Brand-new working mode integrating material receiving, chambering, flattening and arranging

A working mode, integrated technology, applied in the direction of winding capacitor machine, capacitor manufacturing, electrical components, etc., can solve the problems of reducing manual adjustment operation, cumbersome, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

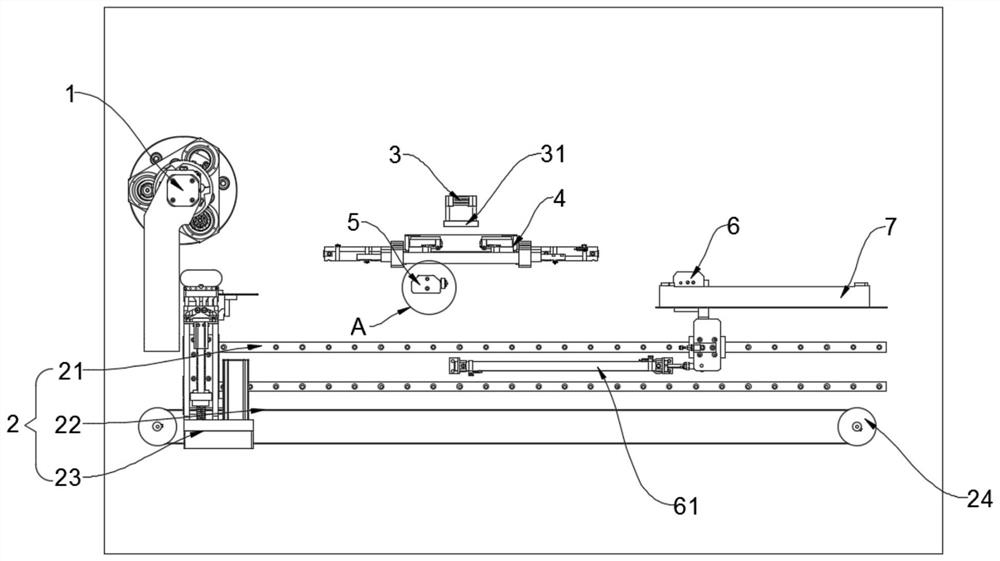

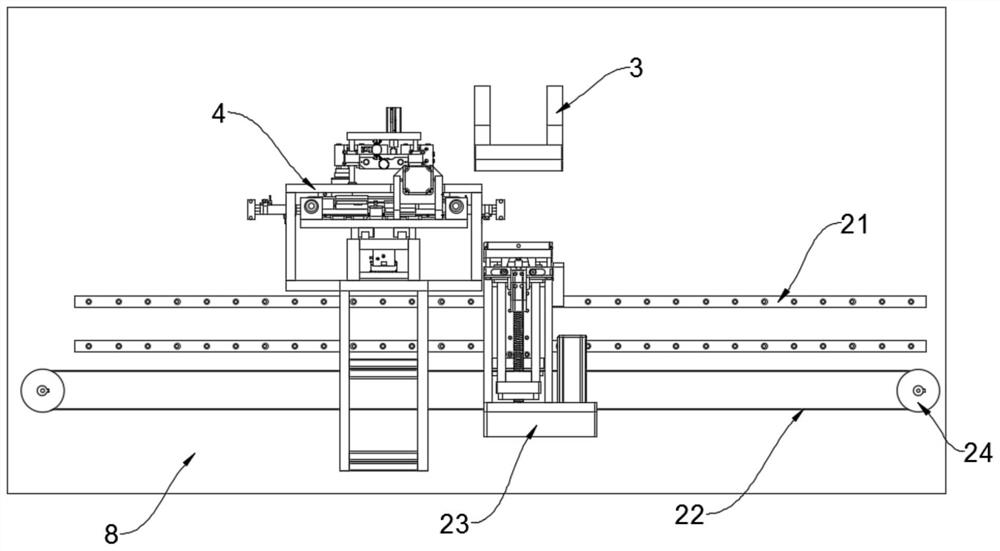

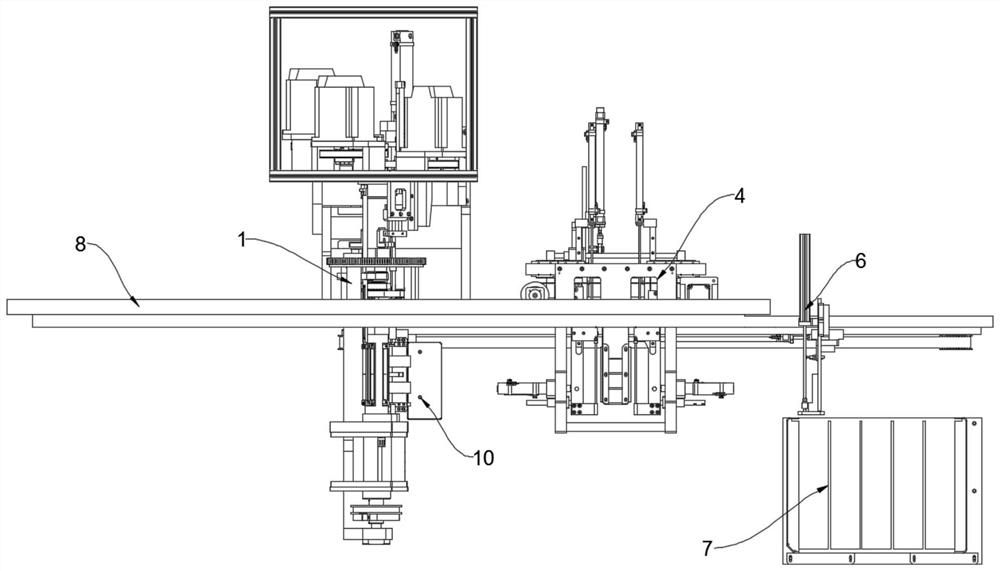

[0038]A brand-new working method integrating material receiving, hole reaming, flattening and arrangement, including winding mechanism 1, conveying component 2, flattening mechanism 3, hole reaming mechanism 4, first core pushing mechanism 5 and second core pushing mechanism Mechanism 6, the winding mechanism 1, the conveying assembly 2, the crushing mechanism 3 and the first core pushing mechanism 5 are all installed on the base plate 8, and the second core pushing mechanism 6 is fixed on the On the conveying assembly 2, the reaming mechanism 4 is located above the first core pushing mechanism 5, the flattening mechanism 3 is located above the reaming mechanism 4, and one side of the conveying assembly 2 is provided with a finished product Arrange rack7.

[0039] The rotating shaft of the pulley 24 is connected to the external power drive equipment.

[0040] The conveying assembly 2 includes a conveying track 21, a conveying belt 22 and a material receiving device 23, the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com