Vertical multi-directional heating organic solid waste pyrolysis device

A technology of organic solid waste and pyrolysis, which is used in the removal, transportation and packaging of solid waste, chemical instruments and methods, etc., can solve the problems of high production cost, popularization and application, many hidden safety hazards and high energy consumption, and can increase the residence time. , the effect of improving production capacity and fully releasing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

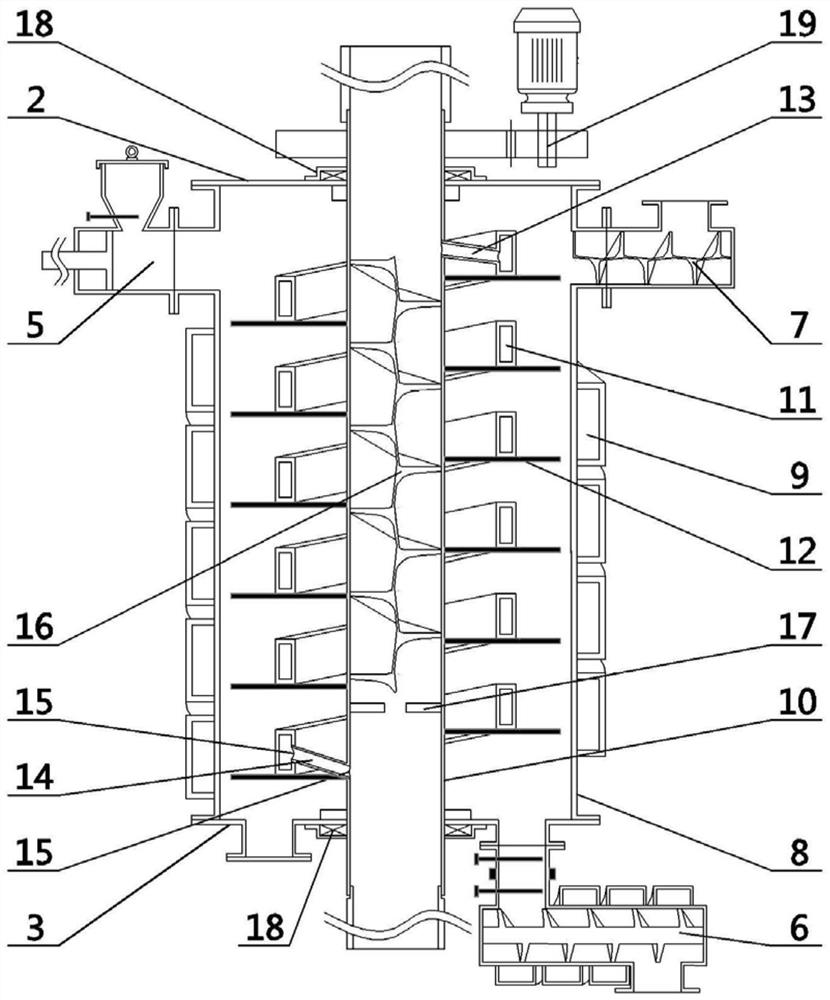

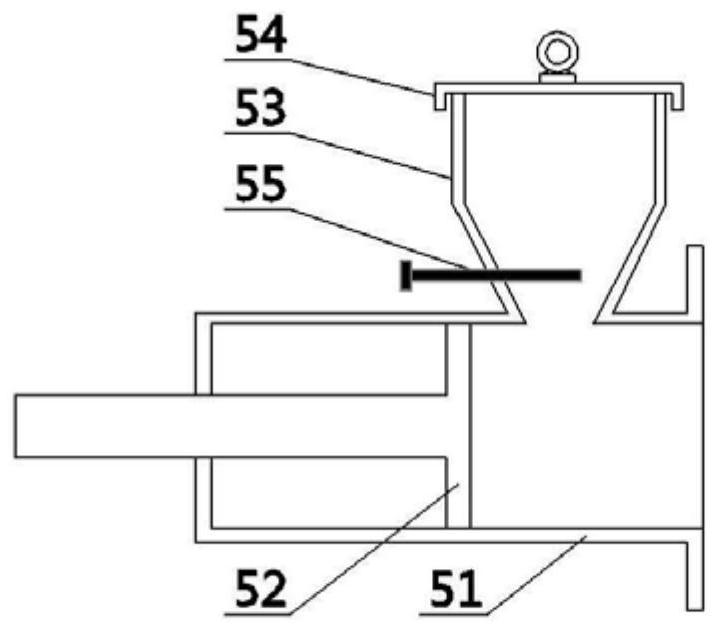

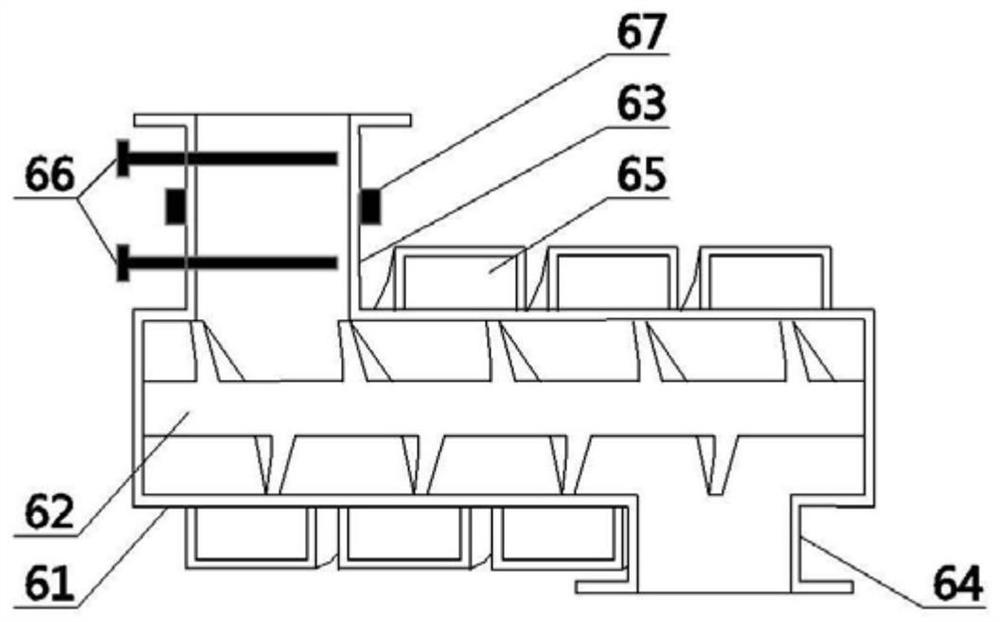

[0032] Such as figure 1 As shown in -7, the vertical multi-directional heating organic solid waste pyrolysis device is characterized in that the device includes an inner cylinder 4, an outer cylinder 1 covering the outer circumference of the inner cylinder 4, and connecting and fixing the outer cylinder 1 and the inner cylinder. The upper end cover 2 and the lower end cover 3 of the cylinder body 4; the closed space formed between the outer cylinder body 1, the inner cylinder body 4 and the upper and lower end covers (2, 3) constitutes the effective space of the pyrolysis device;

[0033] Wherein, the outer cylinder body 1 includes a cylindrical outer cylinder 8, the outer wall of the outer cylinder 8 is coiled with a spiral coil 9 (the cross section is usually rectangular or circular), and the spiral coil 9 coiled around the outer wall of the outer cylinder 8 forms the outer cylinder The spiral heating channel on the outside of body 1, the outlet and inlet of heating gas are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com