Vibration signal and neural network-based TBM disc cutter wear identification system

A vibration signal and disc-shaped hob technology, applied in the direction of biological neural network model, neural architecture, neural learning method, etc., to achieve good accuracy level, good stability and reliability, and high reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

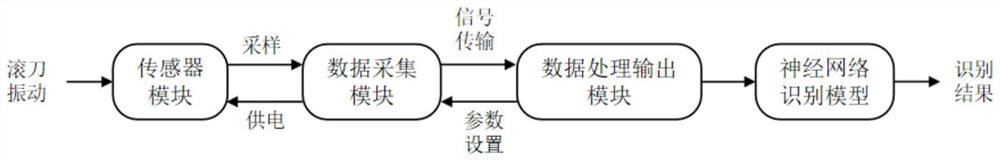

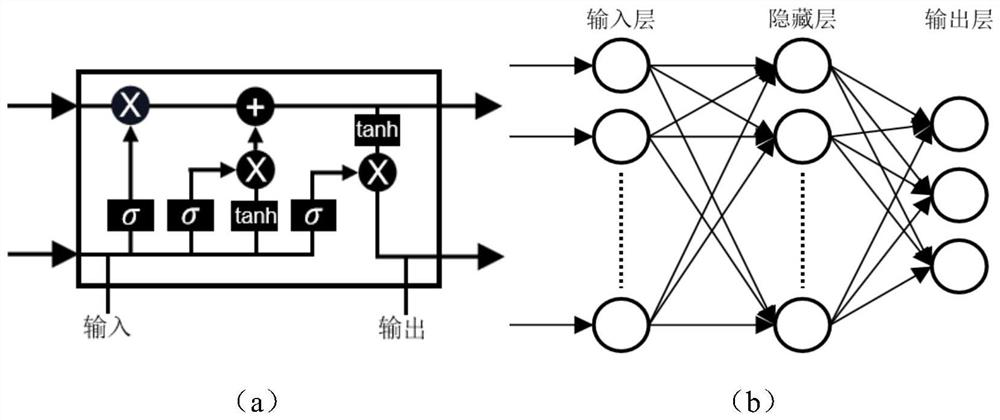

[0022] The invention installs the three-axis vibration acceleration sensor on the hob, directly collects the vibration signal when the hob breaks the rock, analyzes the vibration signal in the time domain, takes the periodic waveform segment for FFT calculation, and obtains the frequency domain characteristics of the periodic waveform segment, The frequency domain features are output as time series data to train the LSTM model to realize the identification and diagnosis of the wear state of a single hob. The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 Shown, a kind of TBM disc hob wear identification system based on vibration signal and neural network of the present invention comprises vibration signal acquisition and processing subsystem and neural network identification model, and vibration signal acquisition and processing subsystem comprises sensor module connected in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com