Shear thickening effect-based milling chatter suppression and deformation control method for thin-wall part

A technology of deformation control and milling chatter, which is applied in the direction of milling machine equipment, manufacturing tools, milling machine equipment details, etc., can solve the problems of not being disclosed, milling vibration without considering forced vibration, and processing chatter of thin-walled parts, etc., to achieve The effect of increasing stiffness and increasing damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

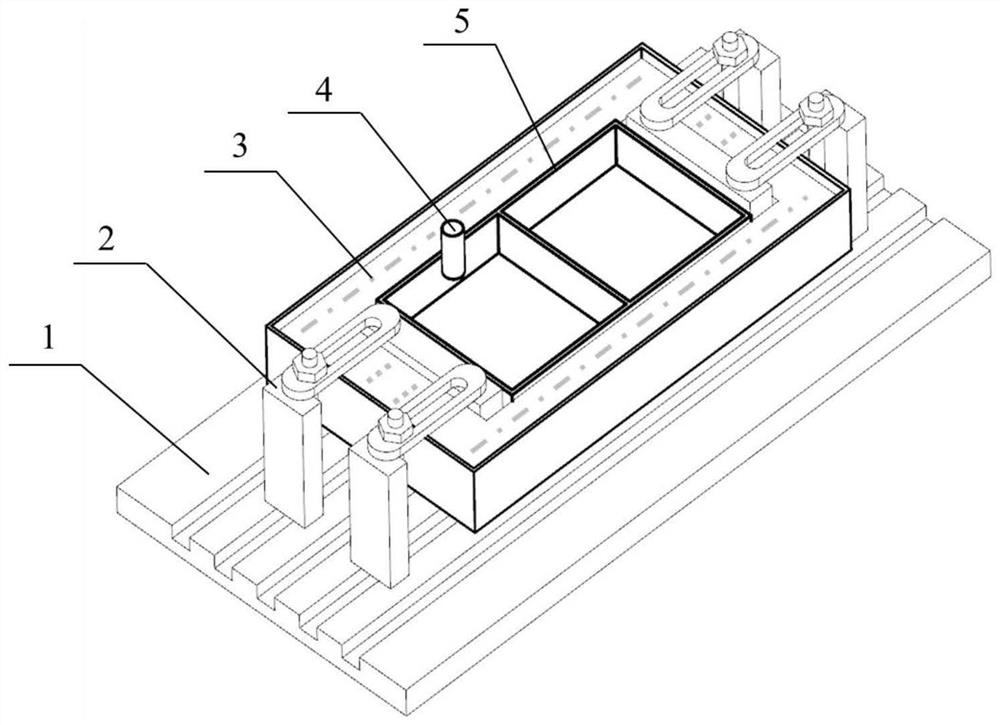

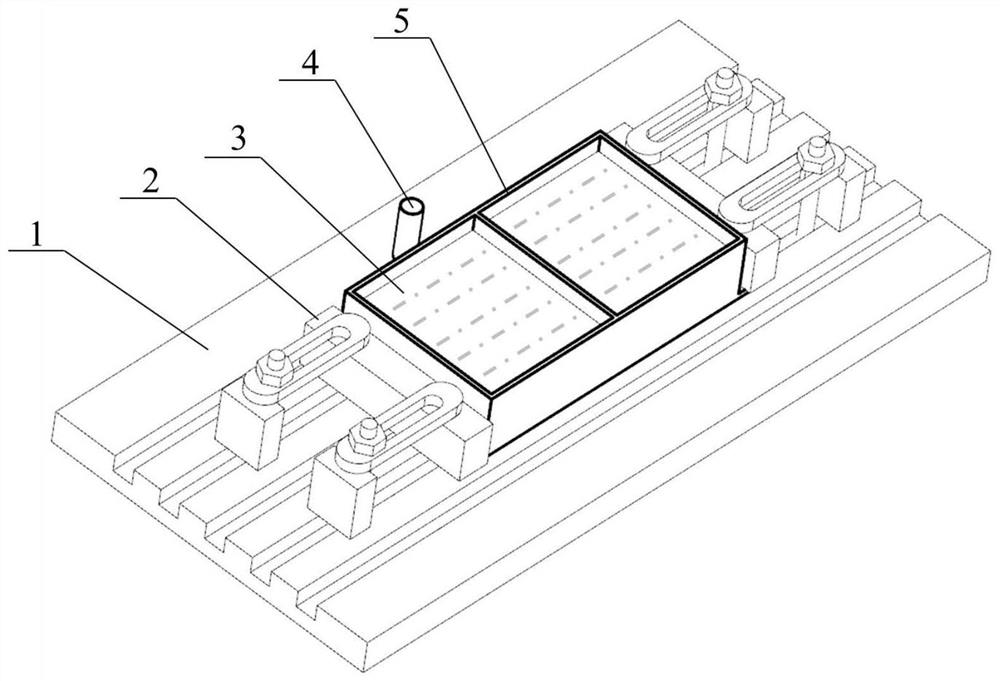

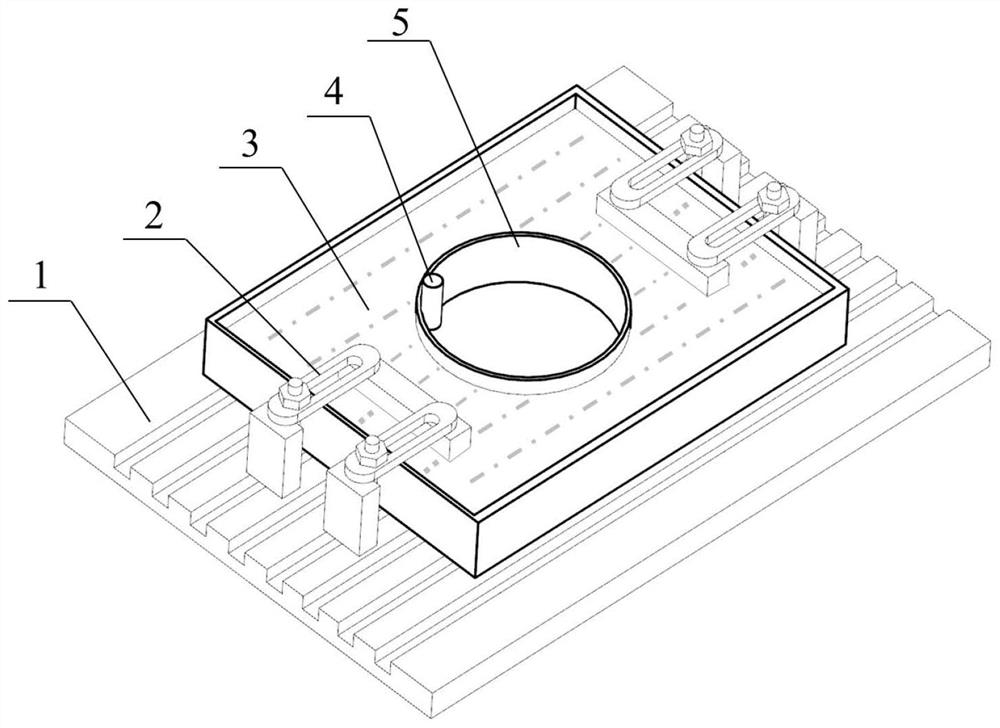

Embodiment 1

[0038] The method is verified by the milling test of thin-walled parts. The shear thickening fluid used in the test is corn starch-water suspension. The workpiece processed in the milling experiment is a thin-walled structural part with two cavities. The workpiece material is aviation aluminum alloy 7075-T7651. Milling tests of thin-walled parts were carried out with and without the addition of corn starch-water suspension. The machine tool used in the test was the Hurco five-axis machining center VMX42UI, and the test tool was hard alloy knives. In the milling experiment, the acceleration sensor PCB352C33 and the dynamic signal acquisition instrument DHDAS8302 are used to collect and analyze the vibration acceleration signal, and the sampling frequency is 5kHz. The milling parameters are cutting speed 376.8m / min, feed per tooth 0.05mm, milling width 0.5mm, axial depth of cut 9mm, and workpiece thickness after machining is 2.5mm. The experimental results show that, in the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com