High-strength fastener for bridge in marine atmosphere and humid environments

A wet environment, marine atmosphere technology, applied in the field of fasteners, can solve the problems of easy damage of the surface coating, poor resistance to hydrogen embrittlement, loss of protection, etc., to achieve excellent anti-rust, improve corrosion resistance, and delay corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

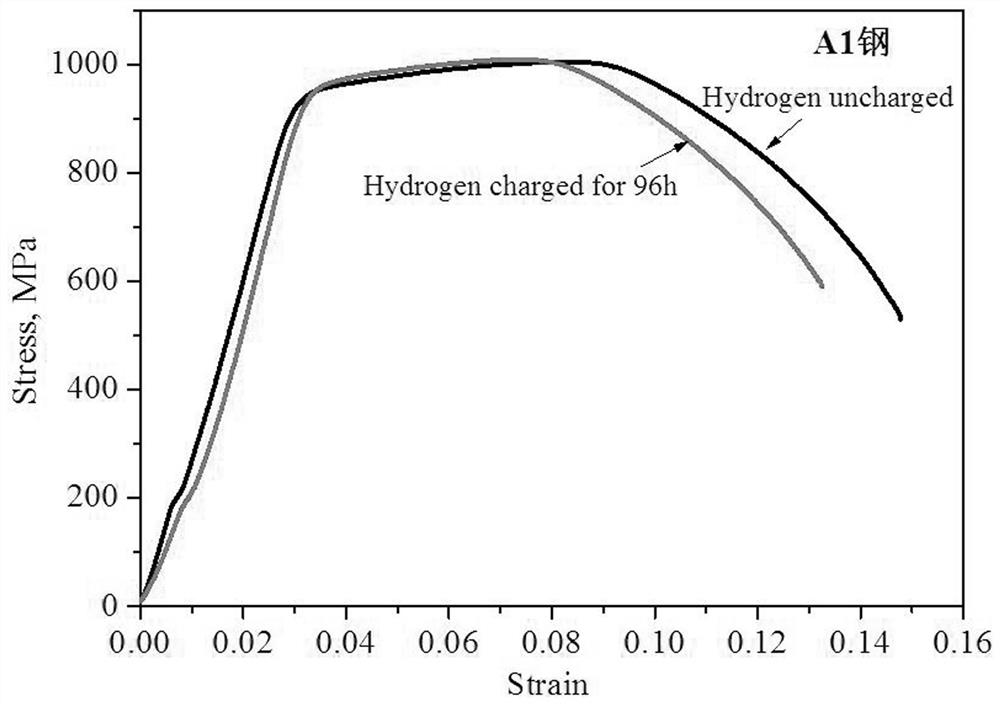

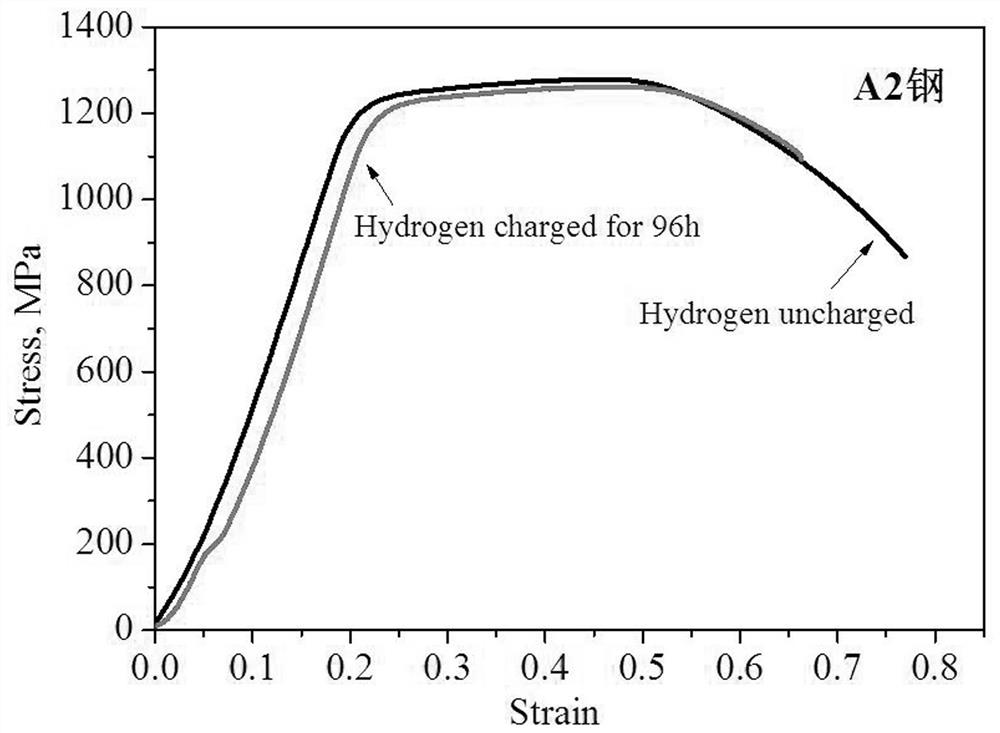

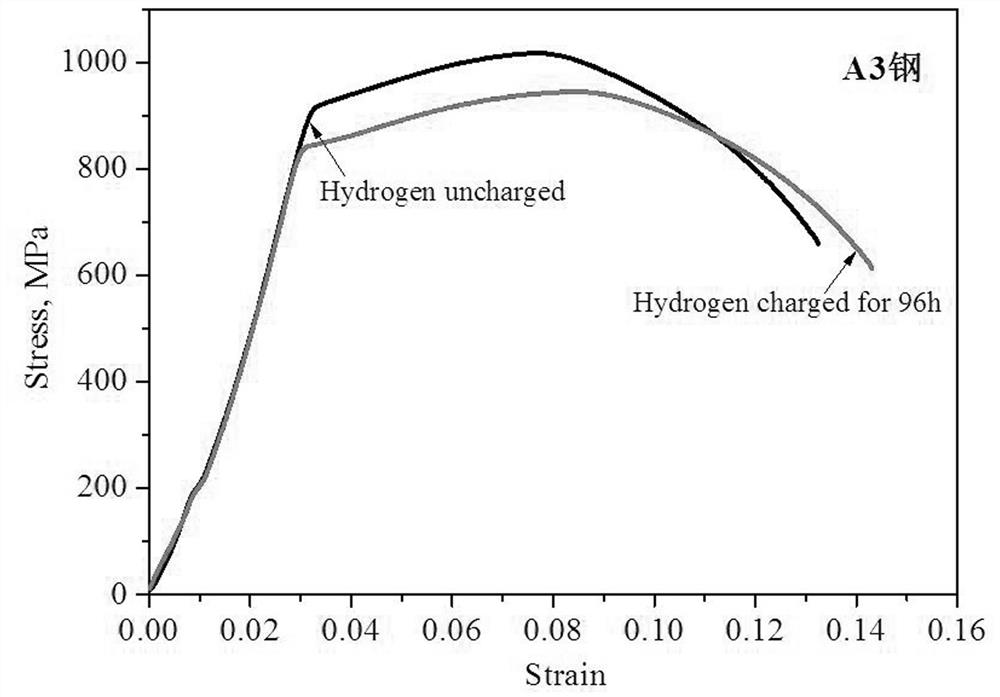

[0048] The chemical composition (mass percentage) of the steel for high-strength bolts used in the high-strength bolts for bridges with wide-range diameters and good hydrogen embrittlement resistance of the present invention is: C 0.07-0.25%, Si 0.20-0.50% , Mn 0.20-0.80%, S≤0.035%, P≤0.035%, Ni 1.00-5.50%, Cr 0.35-1.50%, Mo 0.30-1.50%, V 0.02-0.10%, Cu≤0.30%, the balance is Fe and trace impurities.

[0049] The steel type described in the present invention is suitable for producing high-strength bolts with a diameter of ≤150mm.

[0050] The cathodic dense coating for high-strength bolts in the present invention has a composite sandwich structure: Ni-W-P / Ni / Ni-Co, so as to obtain more excellent corrosion resistance and mechanical damage resistance. The corrosion potential difference between Ni-Co and Ni layer is controlled at 100mV, and the corrosion potential difference between the innermost layer of Ni-W-P and the substrate and the middle Ni layer is controlled at about 150...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com