Polytetrafluoroethylene sealing friction material for hydraulic oil cylinder and preparation method thereof

A polytetrafluoroethylene, sealing friction technology, applied in the field of sealing friction materials, can solve problems such as no clear application of sealing parts, and achieve the effect of reducing stress, ensuring service life and reliability, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

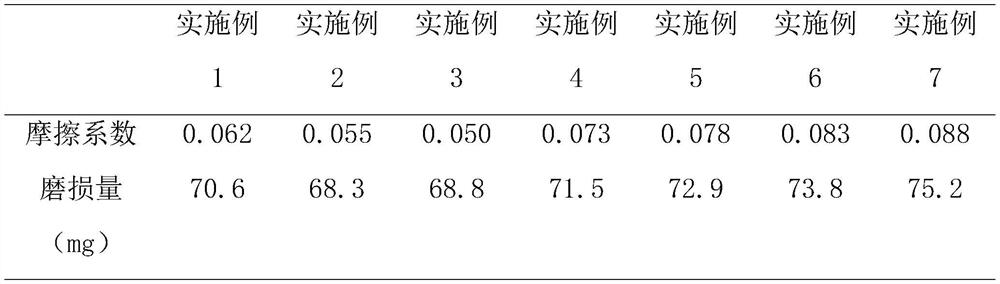

[0023] 50% by mass of polytetrafluoroethylene powder, 40% of carbon fiber and 10% of graphite powder were mixed in a high-speed mixer to prepare a billet, the rotation speed was 1500 rpm, and the mixing time was 1 minute. After taking it out and standing it for 15 minutes, put it back into the high-speed mixer, and mix again according to the same rotation speed and time. The mixed billet was cold-pressed in a mold at room temperature, with a cold-pressing speed of 0.1 mm / s, a final cold-pressing pressure of 40 MPa, and a holding time of 5 minutes. The billet was removed from the mold and left to stand for 24 hours. Sinter the above formed billet in a sintering furnace with a heating rate of 10°C / hour, a holding temperature of 370°C, a holding time of 2 hours, and a cooling rate of 10°C / hour to obtain a PTFE sealing material. Test the wear resistance and friction reduction performance of PTFE sealing material in 46# anti-wear hydraulic oil, using a reciprocating friction testi...

Embodiment 2

[0025] Change the mass ratio in Example 1 to 50% polytetrafluoroethylene powder, 35% carbon fiber and 15% graphite powder, and keep other process conditions unchanged to obtain the PTFE sealing material. Test the wear resistance and friction reduction performance of PTFE sealing material in 46# anti-wear hydraulic oil, using a reciprocating friction testing machine, the load is 28MPa, the reciprocating speed is 0.2m / s, and the wear time is 1h. The results are shown in Table 1. .

Embodiment 3

[0027] Change the mass ratio in Example 1 to 50% polytetrafluoroethylene powder, 30% carbon fiber and 20% graphite powder, and keep other process conditions unchanged to obtain the PTFE sealing material. Test the wear resistance and friction reduction performance of PTFE sealing material in 46# anti-wear hydraulic oil, using a reciprocating friction testing machine, the load is 28MPa, the reciprocating speed is 0.2m / s, and the wear time is 1h. The results are shown in Table 1. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com