Preparation method of oxygen-vacancy-enriched multivalent cobalt in-situ doped ZnO flower-like microsphere composite photocatalyst

An in-situ doping and multi-valence technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of reducing band gap energy and photogenerated current carrying Problems such as sub-separation did not play a key role, to achieve the effect of improving degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

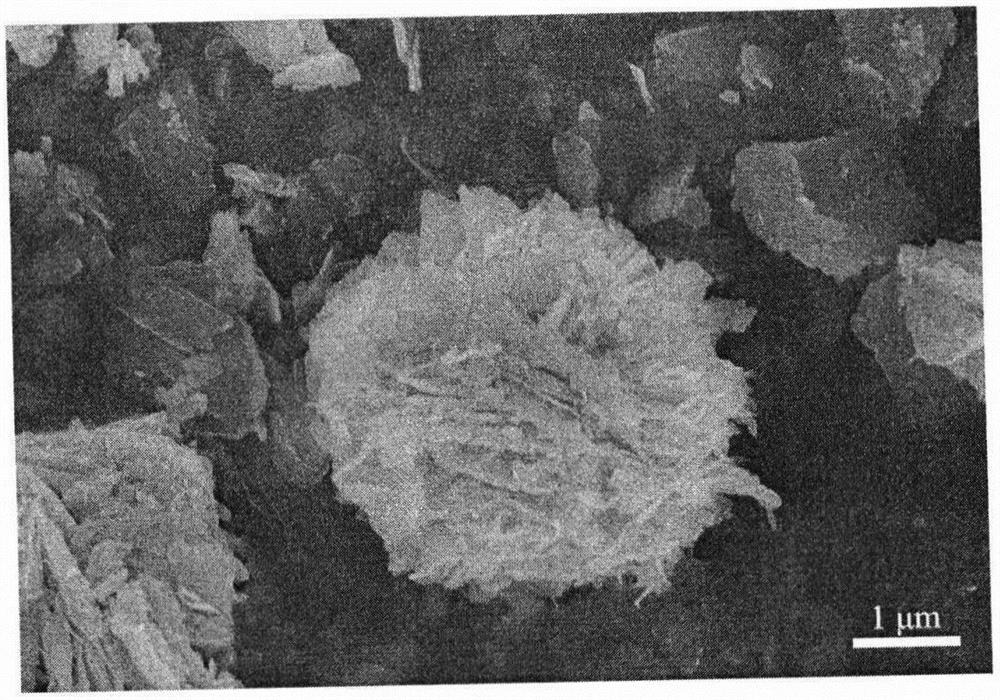

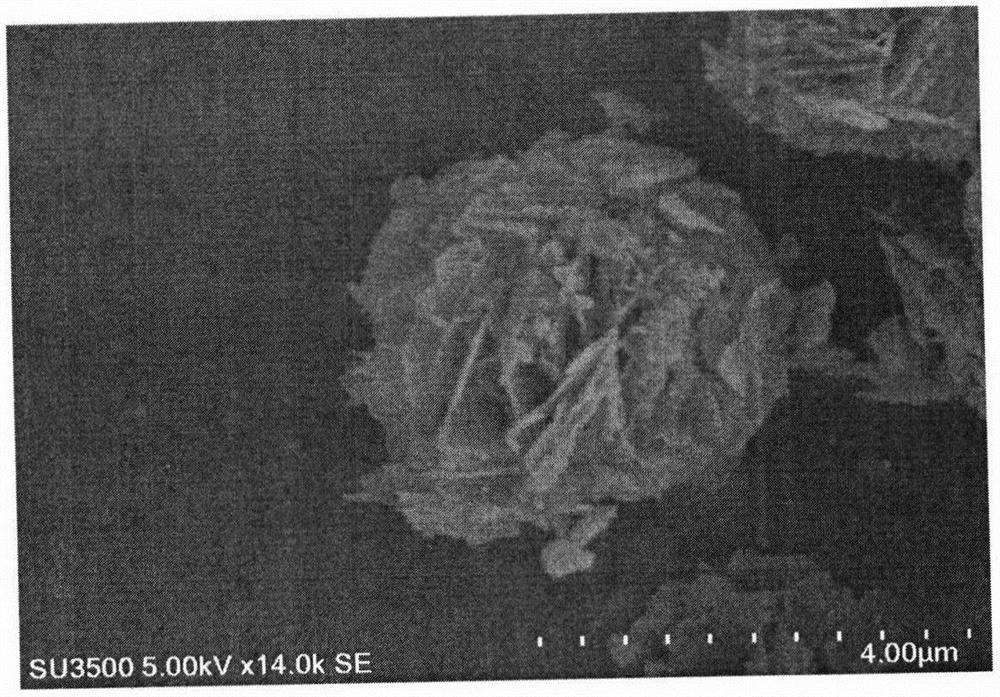

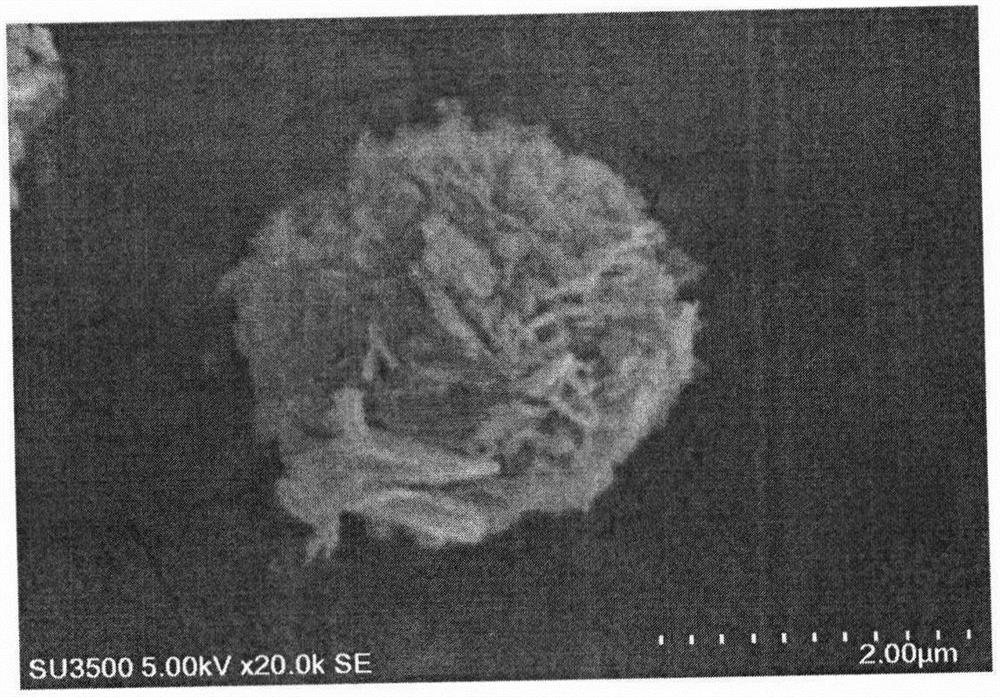

[0048] A method for preparing a composite photocatalyst doped with ZnO flower-like microspheres in-situ with multivalent state cobalt rich in oxygen vacancies, comprising the following steps:

[0049] First, 0.44 g of zinc acetate dihydrate, 0.025 g of cobalt acetate tetrahydrate, 0.24 g of urea and 1 g of sodium lauryl sulfate were dissolved in 80 mL of deionized water, and the above solution was magnetically stirred until the solution became clear. Transfer the resulting solution to a 100mL autoclave and react at 160°C for 12 hours. After cooling down to room temperature, the mixture solution was centrifuged with deionized water, washed three times, and dried in a vacuum oven at 40°C for 72 hours. . The above product was ground with a mortar and placed in a tube furnace. Under a nitrogen atmosphere, the temperature was raised to 400°C at 10°C / min and kept for 6 hours. Finally, the oxygen-rich multivalent state cobalt in-situ doped ZnO flower was obtained. microsphere compos...

Embodiment 2

[0051] A kind of preparation method of oxygen-rich vacancy multivalent state cobalt in-situ doped ZnO flower-shaped microsphere composite photocatalyst, the difference with embodiment 1 is: the weak base selected in the step (1) is pyridine, and all the other conditions are different Change.

Embodiment 3

[0053] A kind of preparation method of oxygen-rich vacancy multivalent cobalt in-situ doped ZnO flower-shaped microsphere composite photocatalyst, the difference from Example 1 is: the weak base selected in step (1) is triethylamine, the rest Conditions remain the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com