Double-layer asymmetric dressing for promoting skin wound repair and preparation method thereof

A wound repair, asymmetric technology, applied in spinning solution preparation, pharmaceutical formula, medical science, etc., can solve the problems of poor affinity of the wound area, insufficient water vapor permeability, etc., to achieve excellent biocompatibility, effective Facilitate adhesion and growth, improve quality and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

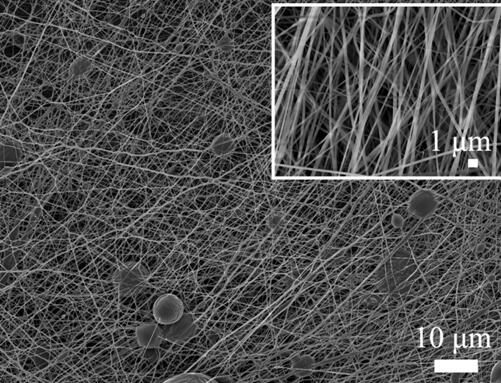

[0020] Preparation of nanofibrous membrane by electrospinning: mix polycaprolactone (PCL) and polylactic acid (PLA) with a mass ratio of 2:1 and dissolve in dichloromethane (DCM) and N-N- In dimethylformamide (DMF) blend solution, at room temperature, magnetically stirred for 24 hours at a speed of 1000r / min, then placed in a magnetic ultrasonic cleaner for 20 minutes to remove air bubbles in the solution, and finally obtained an electrospinning solution. Put the spinning solution in a syringe (20ml), connect the polytetrafluoroethylene hose (1m) and the spinning needle (21G) with an adapter, at an ambient temperature of 25°C, a humidity of 25%, a spinning voltage of 24KV, and a drum speed Under the conditions of 300r / min and spinning extrusion speed of 0.003mm / s, the spinning time lasted 6h to obtain polycaprolactone (PCL) / polylactic acid (PLA) composite electrospun nanofiber membrane.

[0021] Preparation of hydrogel scaffold by 3D printing method: Pour 1.2g polyvinyl alcoho...

Embodiment 2

[0025] The preparation of the electrospun nanofiber membrane, the 3D printed hydrogel scaffold, and the silk fibroin nanofiber solution was the same as in Example 1.

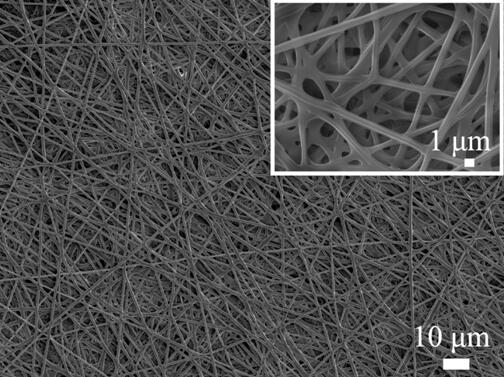

[0026] 3.6g polylactic acid (PLA) was dissolved in 14ml of dichloromethane (DCM) and 6ml of N-N-dimethylformamide (DMF) blend solution, and the upper film was obtained by electrospinning; 1.2g of polyvinyl alcohol ( PVA), 1g sodium alginate (SA), 0.2g chitosan quaternary ammonium salt (HACC) powder were dissolved in 20ml deionized water and mixed evenly, and the hydrogel bottom bracket was prepared by 3D printing method. Dip 0.5ml~1ml of silk fibroin nanofiber solution with a concentration of 0.5wt%~2wt%, and bond the two together. A bilayer asymmetric dressing that promotes wound repair is produced. The average fiber diameter of the electrospun membrane was measured to be 1000nm~1300nm, the water contact angle was 115°~118°, the tensile modulus was 1.8 MPa~2.2 MPa, and the cell survival rates of 1d, 3d, and 5d...

Embodiment 3

[0028] The preparation of the electrospun nanofiber membrane, the 3D printed hydrogel scaffold, and the silk fibroin nanofiber solution was the same as in Example 1.

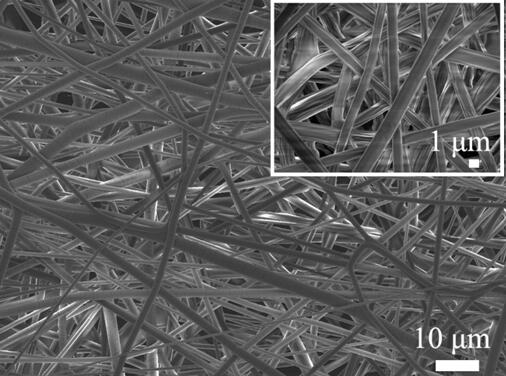

[0029] Dissolve 2.4g of polycaprolactone (PCL) and 1.2g of polylactic acid (PLA) in 14ml of dichloromethane (DCM) and 6ml of N-N-dimethylformamide (DMF) blend solution, prepared by electrospinning Upper layer membrane: 1g of sodium alginate (SA), 0.2g of chitosan quaternary ammonium salt (HACC) powder was dissolved in 20ml of deionized water and mixed evenly, and the hydrogel bottom layer scaffold was prepared by 3D printing. Dip 0.5ml~1ml of silk fibroin nanofiber solution with a concentration of 0.5wt%~2wt%, and bond the two together. A bilayer asymmetric dressing that promotes wound repair is produced. The average fiber diameter of the electrospun membrane was measured to be 700nm~800nm, the water contact angle was 118°~120°, the tensile modulus was 19.11 MPa~20.41 MPa, and the cell survival rates of 1d, 3d,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com