Method for continuously preparing glyoxylic acid through oxalic acid electrolysis

A technology of glyoxylic acid and oxalic acid, applied in the direction of electrolytic components, electrolytic process, electrolytic organic production, etc., can solve the problems of increasing equipment and operating costs, hidden dangers of industrial production explosion, and many solution preparation tanks, so as to promote continuous production, Reduction of operating and investment costs and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

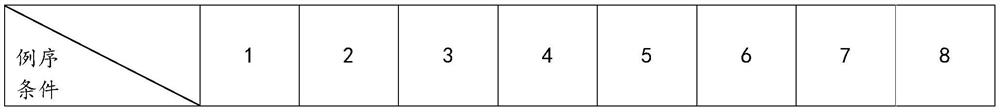

Examples

Embodiment 1

[0043] The invention provides a method for continuously preparing glyoxylic acid by electrolysis of oxalic acid, such as figure 1 As shown, it includes cathode storage tank 1, cathode storage tank 2, anode storage tank 3, cathode gas-liquid separation tank 4, anode gas-liquid separation tank 5 and several electrolyzer modules 6, the cathode storage tank 2 and anode storage tank The tanks 3 are all jacketed storage tanks, and a cooling liquid is arranged between the jackets, and the cooling liquid adopts a circulating flow setting. The cathode storage tank 2 and the anode storage tank 3 can also remove the jacket, and add a heat exchanger instead. Cathode storage tank 1, cathode storage tank 2, and anode storage tank 3 are made of glass-lined or plastic materials, and metal materials cannot be used. The cathode storage tank 1, cathode storage tank 2, and anode storage tank 3 are all set inside There is an agitator, and several electrolyzer modules 6 are equally divided into an ...

specific Embodiment approach

[0055] As a specific embodiment of the present invention, the method for continuously preparing glyoxylic acid by electrolysis of oxalic acid comprises the following steps:

[0056] Preparation of raw materials at the cathode end of S1: First, pour desalted water, oxalic acid crystals and quaternary ammonium salt solid additives into the cathode storage tank 1 at a ratio of 5-8%wt of oxalic acid oxalic acid, 0.1-0.5%wt of additives, and the balance of water. Stir until the solids are all dissolved, open the cathode circulation valve 22, let the catholyte flow into the cathode feed main pipe 7 through the cathode pump 8, and then evenly inject into the multiple groups of parallel electrolyzer modules 6 through the liquid distributor 16 according to the flow rate requirements In the cathode chamber 602, at this time, the electrolyzer module 6 is not powered, and the heat exchange bypass valve 20 is opened to allow the catholyte to leave the electrolyzer module 6, and then return ...

Embodiment 2

[0065] The invention provides a method for continuously preparing glyoxylic acid by electrolysis of oxalic acid, comprising the following steps:

[0066]Preparation of raw materials at the cathode end of S1: First, pour desalted water, oxalic acid crystals and quaternary ammonium salt solid additives into the cathode storage tank 1 at a ratio of 5-8%wt of oxalic acid oxalic acid, 0.1-0.5%wt of additives, and the balance of water. Stir until the solids are all dissolved, open the cathode circulation valve 22, let the catholyte flow into the cathode feed main pipe 7 through the cathode pump 8, and then evenly inject into the multiple groups of parallel electrolyzer modules 6 through the liquid distributor 16 according to the flow rate requirements In the cathode chamber 602, at this time, the electrolyzer module 6 is not powered, and the heat exchange bypass valve 20 is opened to allow the catholyte to leave the electrolyzer module 6, and then return to the cathode storage tank a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com