Interface composite modification method of positive electrode material, positive electrode material and application

A technology of interfacial compounding and positive electrode material, applied in positive electrodes, chemical instruments and methods, nickel compounds, etc., can solve the problems of reduced discharge specific capacity rate performance, no strong chemical bonding, uneven local coating, etc. The effect of improving rate performance, improving material structure stability, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

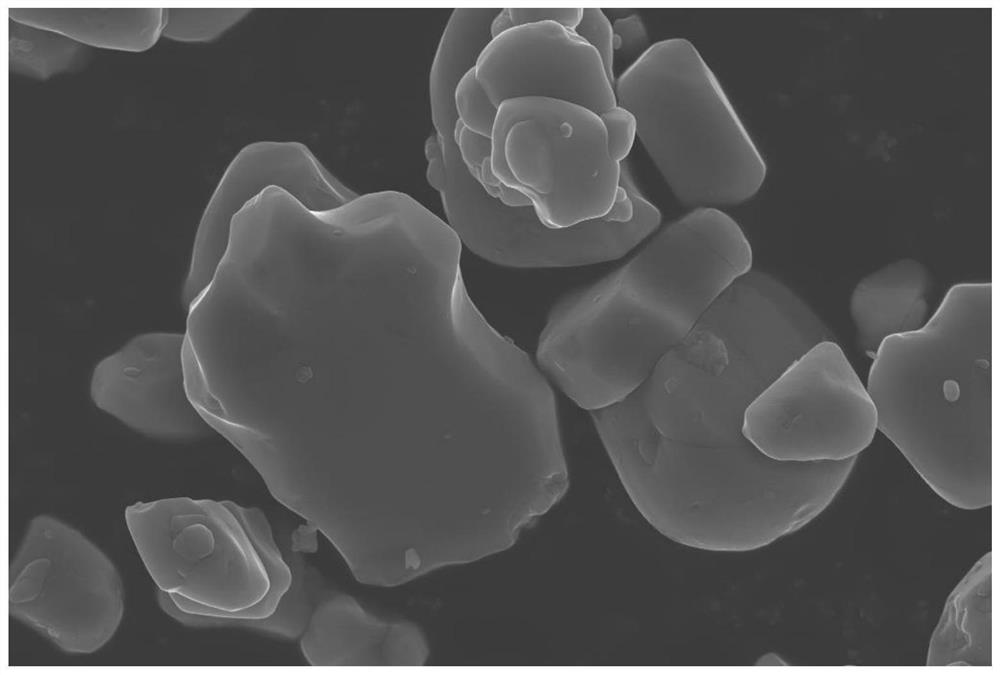

Image

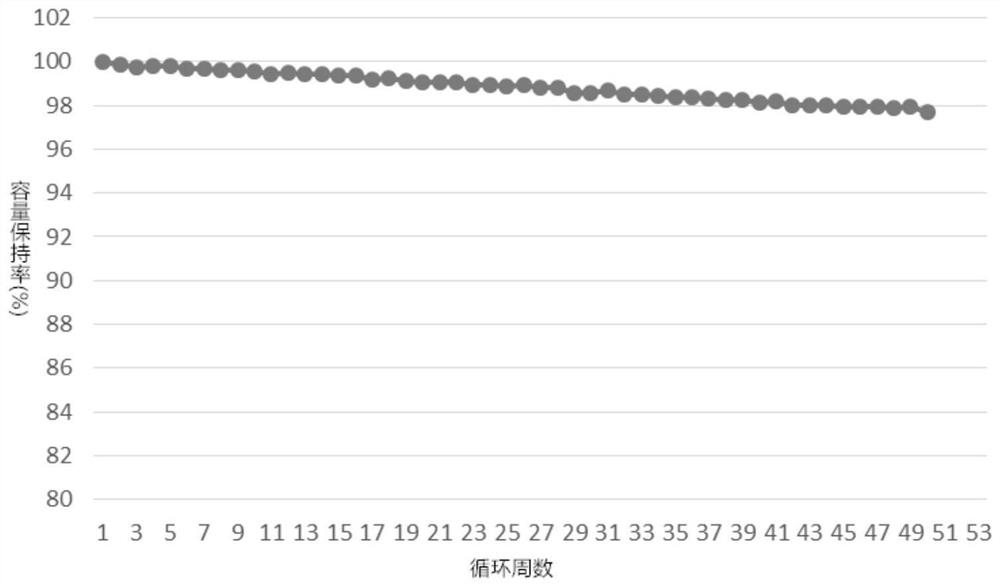

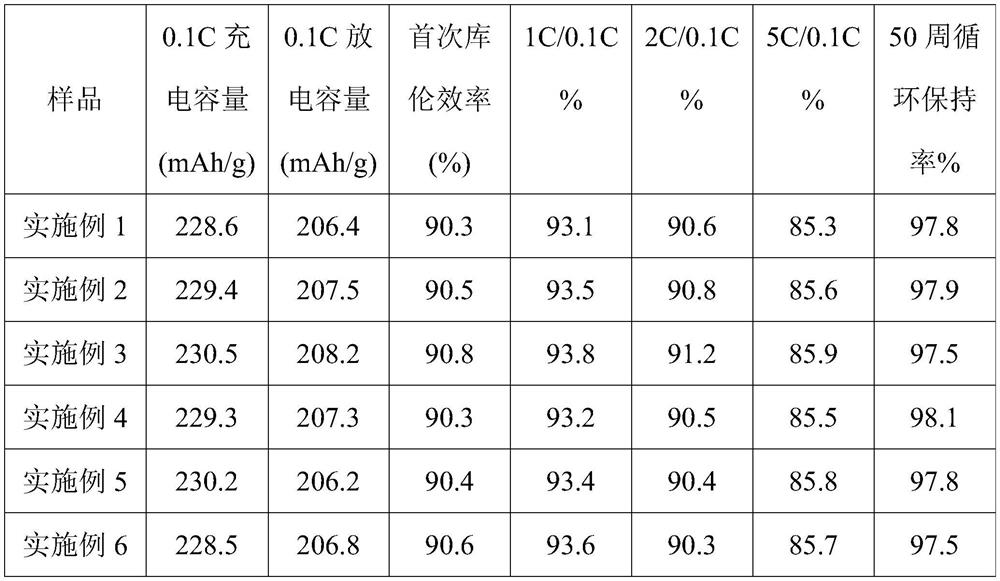

Examples

Embodiment 1

[0054] This embodiment provides a method for interfacial composite modification of nickel-cobalt lithium manganese oxide positive electrode material. The interface composite modification method specifically includes the following steps:

[0055] (Ⅰ) Precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 , Li(OH) 2 After mixing with nano zirconia for 10min once, Li(OH) 2 and the precursor according to the molar ratio of Li:(Ni+Co+Mn)=1, the addition of nano-zirconia is the precursor and Li(OH) 2 500ppm of the total mass;

[0056] (II) The material after primary mixing is placed in an oxygen atmosphere (oxygen concentration ≥ 99.99%) with an oxygen flow rate of 5L / min, heated to 800°C at a heating rate of 2°C / min, kept for 15h, and sintered after sieving;

[0057] (Ⅲ) The sintered material, cyanuric acid and boric acid were mixed for 10 minutes according to the mass ratio of 1:0.2:0.3, and then placed in a nitrogen atmosphere, and the temperature was raised to 300°C at a heating rate of 2°...

Embodiment 2

[0059] This embodiment provides a method for interfacial composite modification of nickel-cobalt lithium manganese oxide positive electrode material. The interface composite modification method specifically includes the following steps:

[0060] (Ⅰ) Precursor Ni 0.82 co 0.08 mn 0.1 (OH) 2 , Li(OH) 2 After mixing with nano-titanium oxide for 14min once, Li(OH) 2 According to the mol ratio of Li:(Ni+Co+Mn)=1.05 feeding intake with the precursor, the addition of nano-titanium oxide is the precursor and Li(OH) 1000ppm of the total mass;

[0061] (II) The materials mixed once are placed in an oxygen atmosphere (oxygen concentration ≥ 99.99%) with an oxygen flow rate of 8L / min, heated to 830°C at a heating rate of 2.5°C / min, kept for 13h, and sintered after sieving;

[0062] (Ⅲ) The sintering material, dicyandiamide and boron oxide were mixed for 14 minutes according to the mass ratio of 1:0.4:0.3, and then placed in a nitrogen atmosphere, and the temperature was raised to 380°...

Embodiment 3

[0065] This embodiment provides a method for interfacial composite modification of nickel-cobalt lithium manganese oxide positive electrode material. The interface composite modification method specifically includes the following steps:

[0066] (Ⅰ) Precursor Ni 0.85 co 0.05 mn 0.1 (OH) 2 , Li(OH) 2and nano tungsten oxide mixed for 18min once, Li(OH) 2 With the precursor according to the molar ratio of Li:(Ni+Co+Mn)=1.08 feed intake, the addition of nano-tungsten oxide is the precursor and Li(OH) 1500ppm of the total mass;

[0067] (II) Put the mixed material once in an oxygen atmosphere (oxygen concentration ≥ 99.99%) with an oxygen flow rate of 10L / min, raise the temperature to 860°C at a heating rate of 3°C / min, keep it warm for 10h, and sinter the material after sieving;

[0068] (Ⅲ) The sintering material, hydroxyethyl urea and boric acid were mixed for 18 minutes according to the mass ratio of 1:0.5:0.4, and then placed in an argon atmosphere, and the temperature wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com