A kind of high-nickel positive electrode material and preparation method thereof

A positive electrode material, high-nickel technology, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve problems that have not been considered, and achieve reduced surface impedance, stable crystal structure, and cycle stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

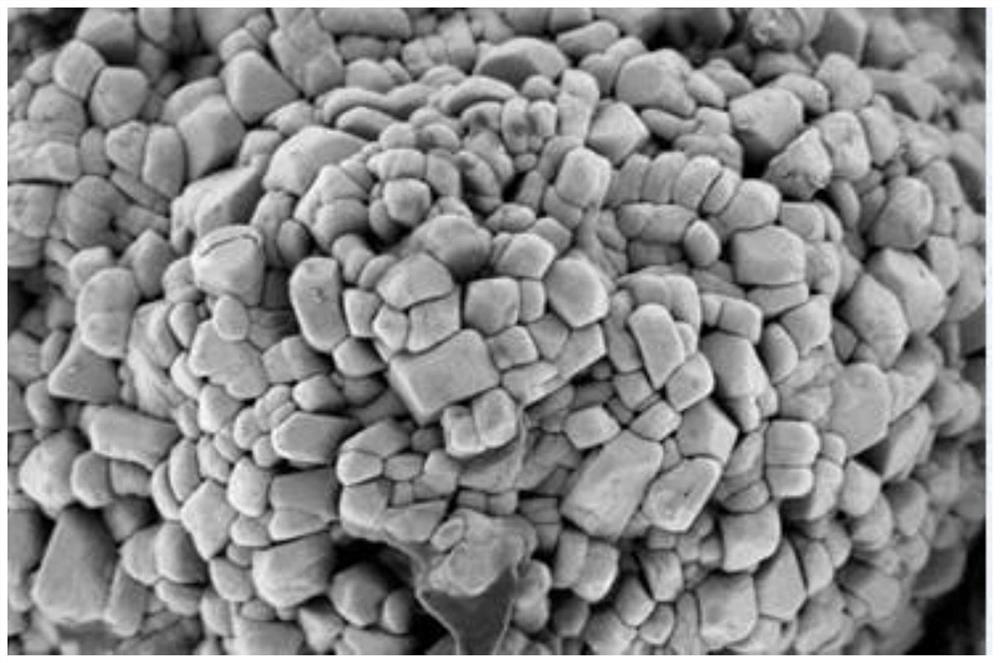

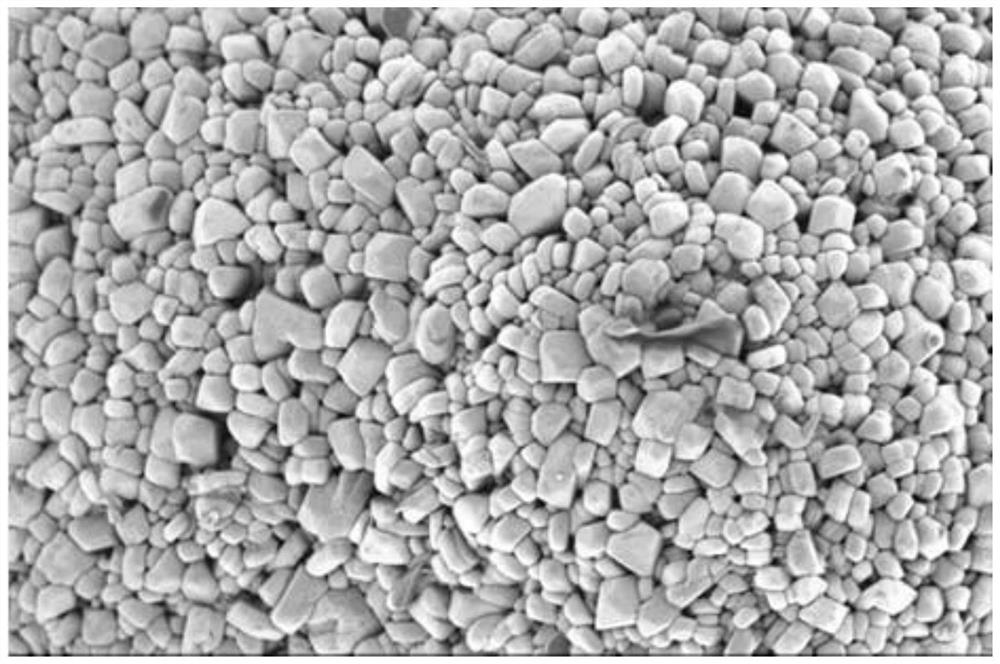

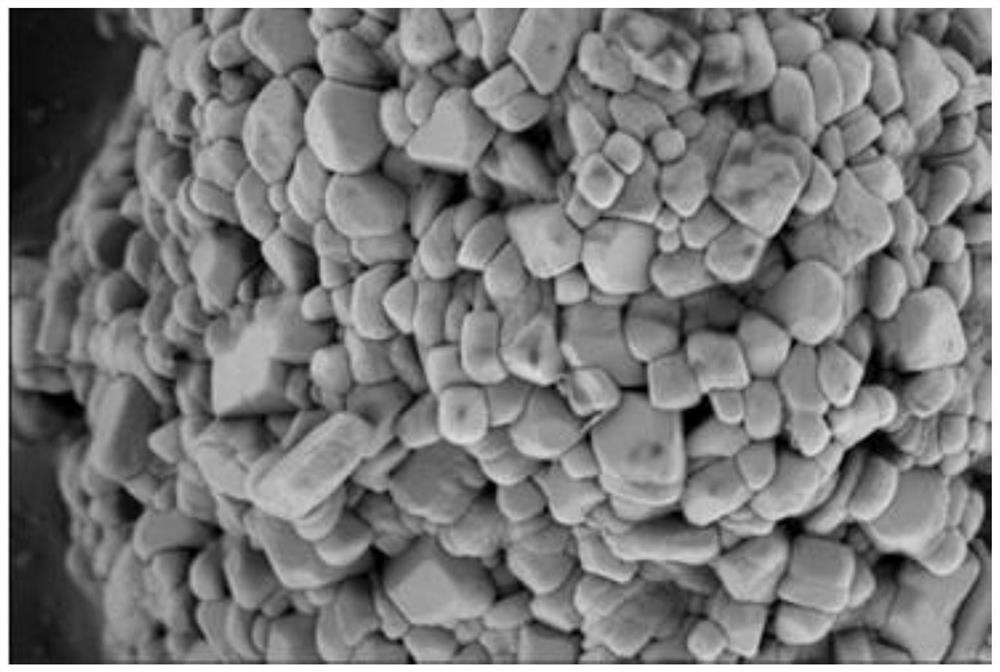

Image

Examples

Embodiment 1

[0029] Precursor Ni 0.83 co 0.12 mn 0.05 (OH) 2 and lithium hydroxide monohydrate in a high-speed mixer according to the molar ratio of Li / (Ni+Co+Mn) of 1.05, and then sintered at 790° C. for 15 hours in a pure oxygen atmosphere to obtain a base material.

[0030] Nano Al 2 o 3 (0.05wt%), nano ZrO 2 (0.1wt%) mixed with the base material at high speed and then annealed at 720°C for 5 hours to obtain a primary modified powder. During annealing, high-purity oxygen was introduced to ensure the sintering atmosphere. The deionized water and primary modified powder were dispersed and stirred for 5 minutes according to the mass ratio of 2:1, and then suction filtered, and the filtered material was dried in a vacuum oven at 120°C for 12 hours, and N 2 Perform atmosphere replacement.

[0031] TiO 2 (0.1wt%) and the washed and dried primary modified powder were uniformly mixed with a high-speed mixer, and then sintered at 600°C for 5 hours in a pure oxygen atmosphere to obtain a ...

Embodiment 2

[0034] Precursor Ni 0.83 co 0.12 mn 0.05 (OH) 2and lithium hydroxide monohydrate in a high-speed mixer according to the molar ratio of Li / (Ni+Co+Mn) of 1.05, and then sintered at 790° C. for 15 hours in a pure oxygen atmosphere to obtain a base material.

[0035] Nano Al 2 o 3 (0.1wt%), nano ZrO 2 (0.1wt%) mixed with the base material at high speed and then annealed at 720°C for 5 hours to obtain a primary modified powder. During annealing, high-purity oxygen was introduced to ensure the sintering atmosphere. The deionized water and primary modified powder were dispersed and stirred for 5 minutes according to the mass ratio of 2:1, and then suction filtered, and the filtered material was dried in a vacuum oven at 120°C for 12 hours, and N 2 Perform atmosphere replacement.

[0036] Will B 2 o 3 (0.1wt%) and the washed and dried primary modified powder were uniformly mixed with a high-speed mixer, and then sintered at 500°C for 5 hours in a pure oxygen atmosphere to obt...

Embodiment 3

[0039] Precursor Ni 0.83 co 0.12 mn 0.05 (OH) 2 and lithium hydroxide monohydrate in a high-speed mixer according to the molar ratio of Li / (Ni+Co+Mn) of 1.05, and then sintered at 790° C. for 15 hours in a pure oxygen atmosphere to obtain a base material.

[0040] Nano Al 2 o 3 (0.1wt%), nano ZrO 2 (0.2wt%) mixed with the base material at high speed and then annealed at 720°C for 5 hours to obtain a primary modified powder. During annealing, high-purity oxygen was introduced to ensure the sintering atmosphere. The deionized water and primary modified powder were dispersed and stirred for 5 minutes according to the mass ratio of 2:1, and then suction filtered, and the filtered material was dried in a vacuum oven at 120°C for 12 hours, and N 2 Perform atmosphere replacement.

[0041] TiO 2 (0.05wt%) and the washed and dried primary modified powder were uniformly mixed with a high-speed mixer, and then sintered at 500°C for 5 hours in a pure oxygen atmosphere to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com