Lithium ion battery positive electrode material as well as preparation method and application thereof

A technology for lithium-ion batteries and positive electrode materials, applied in the field of lithium-ion battery positive electrode materials and its preparation, can solve the problems of first-round charge and discharge capacity decline, positive active material intensification, positive electrode plate overpotential increase, etc., to reduce direct contact, Inhibiting dissolution and reducing the effect of residual alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The first aspect of the present invention provides a kind of preparation method of lithium-ion battery cathode material, comprises the following steps:

[0032] According to the general chemical formula Al 2 Ti 1+a o 5 Dissolving the water-soluble titanium source and aluminum source in water and mixing them uniformly to obtain a mixed solution;

[0033] Mix the polymer hydrogel and the ternary cathode material evenly to obtain the first mixture;

[0034] Dropping the mixed solution into the first mixture under ultrasonic vibration conditions to obtain the second mixture;

[0035] After plasma activation of the second mixture, sintering, crushing and sieving, the lithium ion battery cathode material is obtained.

[0036] In this preparation method, the ternary positive electrode material refers to the conventional ternary positive electrode material LiNi in this field. x co y m 1-x- y o 2 , wherein, M is manganese (Mn) or aluminum (Al), 02 Ti 1+a o 5 (where, a...

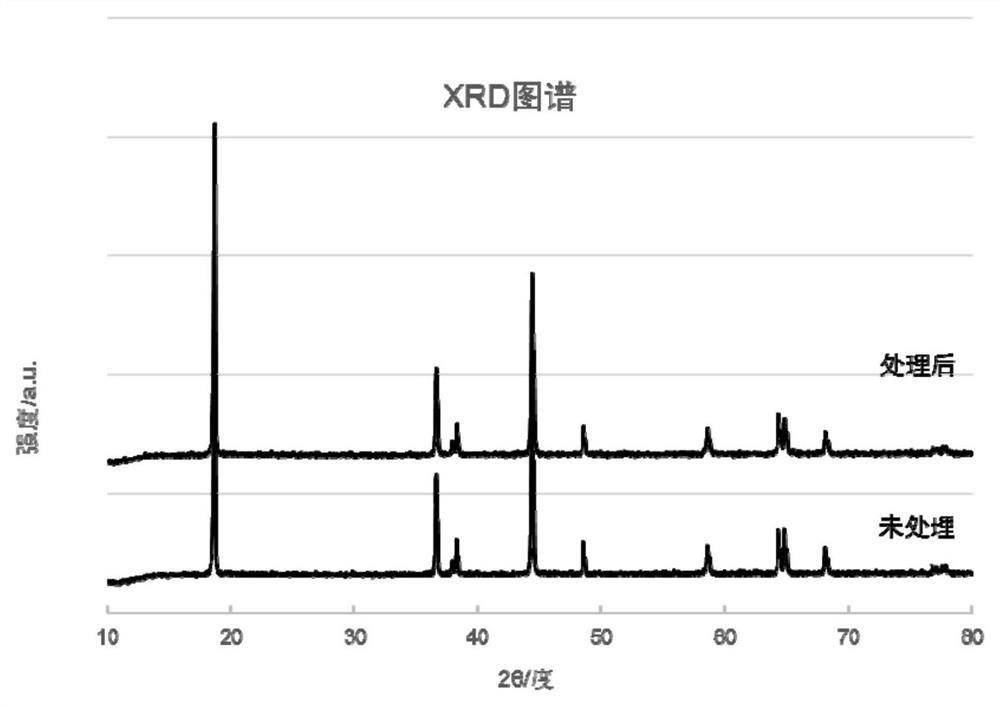

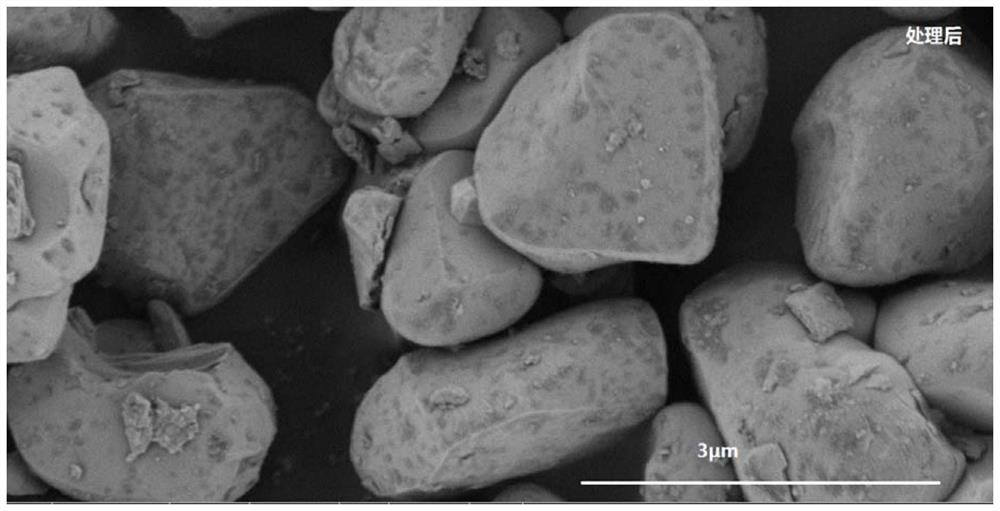

Embodiment 1

[0049] In this embodiment, single crystal LiNi 0.7 co 0.1 mn 0.2 o 2 @Al 2 Ti 1.05 o 5 The specific steps for the preparation of lithium-ion positive electrode materials are as follows:

[0050] According to the chemical formula Al 2 Ti 1.05 o 5 Weigh water-soluble titanium trichloride and aluminum trichloride, dissolve in deionized water, stir evenly with a magnetic force, and obtain a mixed solution with a metal ion concentration of 10 g / L;

[0051] Polyacrylamide hydrogel and single crystal cathode material LiNi 0.7 co 0.1 mn 0.2 o 2 Mix evenly according to the mass ratio of 1:60 to obtain the first mixture;

[0052] Under the condition of ultrasonic vibration, drop the mixed solution into the first mixture to form the second mixture; continue to react under the ultrasonic condition for 1h, wherein, the temperature is 50°C, and the ultrasonic dispersion frequency is 10kHz; then the second mixture Lay it flat on the tray, under the protection of argon, use 100L...

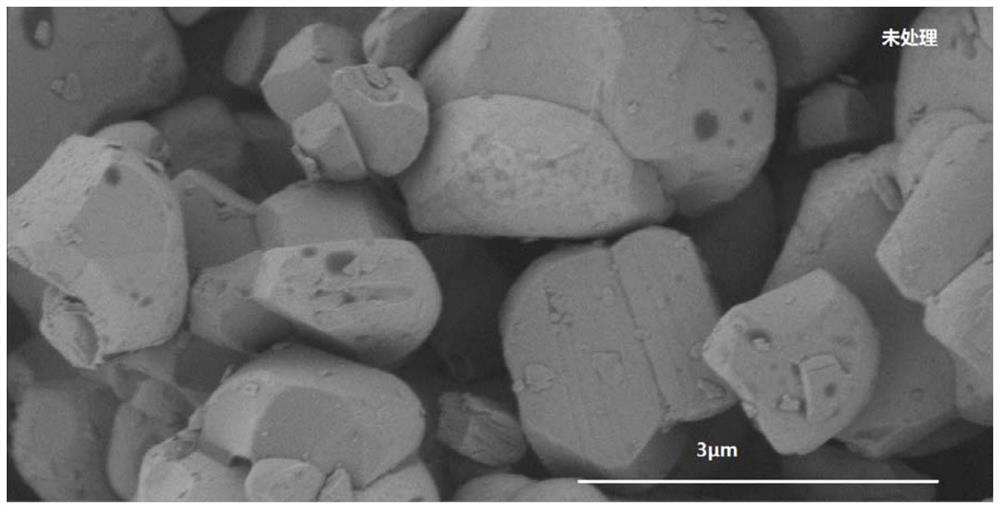

Embodiment 2

[0056] Secondary spherical LiNi in this embodiment 0.7 co 0.1 mn 0.2 o 2 @Al 2 Ti 1.05 o 5 The specific steps for the preparation of lithium-ion positive electrode materials are as follows:

[0057] According to the chemical formula Al 2 Ti 1.05 o 5 Weigh water-soluble titanium trichloride and aluminum trichloride, dissolve in deionized water, stir evenly with a magnetic force, and obtain a mixed solution with a metal ion concentration of 10 g / L;

[0058] Polyacrylic acid hydrogel and secondary spherical cathode material LiNi 0.7 co 0.1 mn 0.2 o 2 Mix evenly according to the mass ratio of 2:90 to obtain the first mixture;

[0059] Under the condition of ultrasonic vibration, drop the mixed solution into the first mixture to form the second mixture; continue to react under the ultrasonic condition for 1h, wherein, the temperature is 50°C, and the ultrasonic dispersion frequency is 15kHz; then the second mixture Lay it flat on the tray, under the protection of argo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com