Method for modifying phosphorus-containing compound on surface of high-nickel ternary material and lithium ion battery

A high-nickel ternary material and modification method technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reduced electrochemical performance, lithium deficiency of high-nickel materials, and dissolution of metal elements, so as to improve capacity performance, The effect of reducing the residual alkali content on the surface and improving the surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

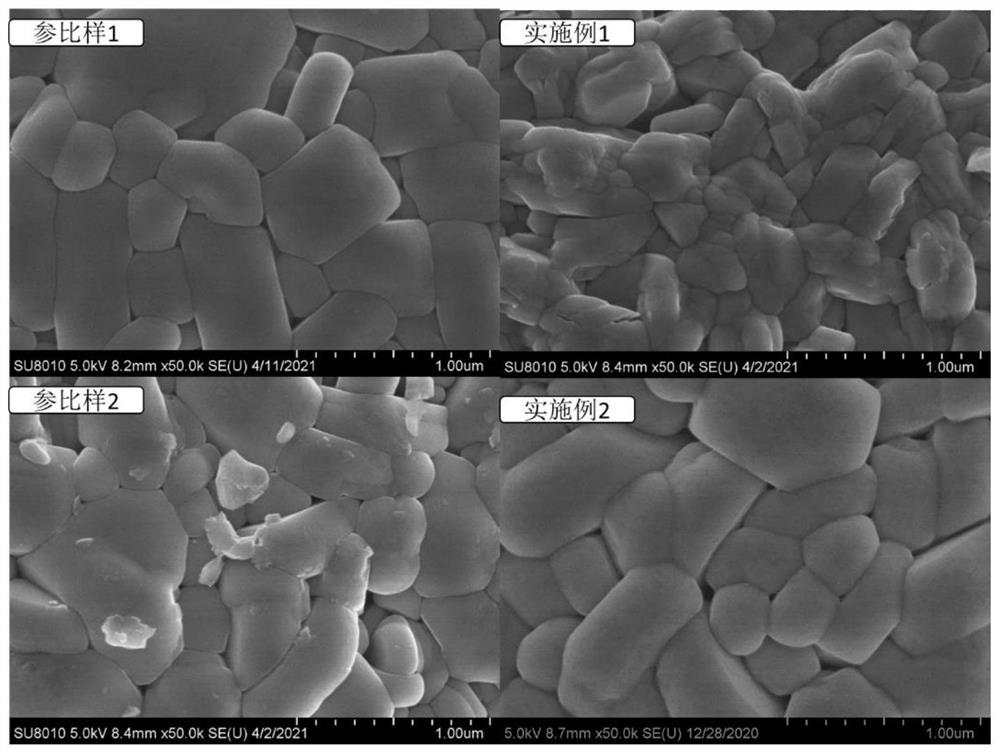

Embodiment 1

[0046] 1kg LiNi 0.96 co y mn z o 2 The material and potassium dihydrogen phosphate are ball milled and mixed by a planetary ball mill; the added content of phosphorus is 3.1*10^-4ppm, and the two materials are mixed in a 300rpm ball mill for 3 hours; the sagger containing the mixed material is placed in oxygen The flux is sintered in a heat treatment furnace of 10L / min; the heating rate of the furnace body is 2°C / min, and the temperature is kept at a high temperature of 600°C for 12h.

Embodiment 2

[0048] 1kg LiNi 0.96 co y mn z o 2 The material and ammonium dihydrogen phosphate are ball milled and mixed by a planetary ball mill; the added content of phosphorus is 1.24*10^-3ppm, and the two materials are mixed in a 300rpm ball mill for 3 hours; the sagger containing the mixed material is placed in oxygen The flux is sintered in a heat treatment furnace of 12L / min; the heating rate of the furnace body is 2°C / min, and the temperature is kept at a high temperature of 600°C for 10h.

[0049] Reference sample 1

[0050] High nickel ternary material LiNi with high surface residual alkali 0.96 co y mn z o 2 .

[0051] Reference sample 2

[0052] 1kg LiNi 0.96 co y mn z o 2 The material and potassium dihydrogen phosphate are ball milled and mixed by a planetary ball mill; the added content of phosphorus is 3.1*10^-4ppm, and the two materials are mixed in a 300rpm ball mill for 3 hours; the sagger containing the mixed material is placed in oxygen The flux is sintere...

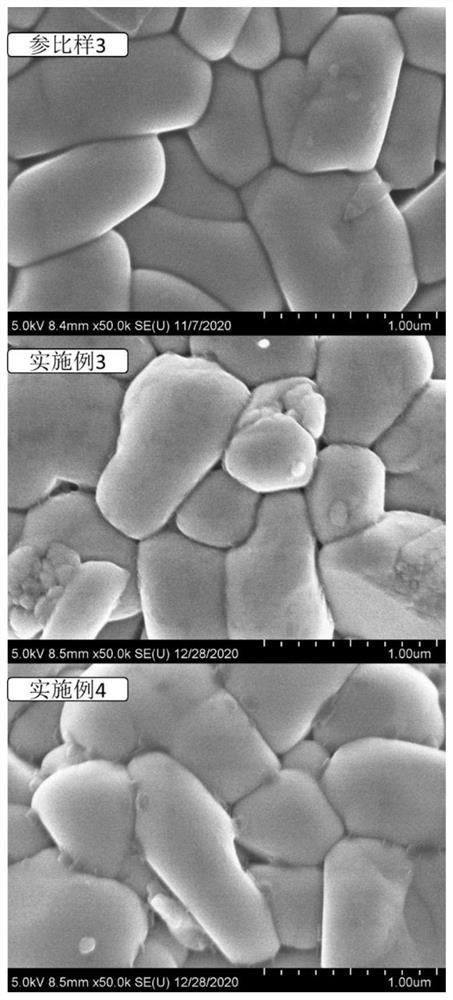

Embodiment 3

[0054] 3kg LiNi 0.96 co y mn z o 2 The material and aluminum dihydrogen phosphate are mechanically mixed by a high-speed mixer at a speed of 1000rpm for 25 minutes; the phosphorus content accounts for 4.65*10^-4ppm; the sagger with the mixed material is placed in a heat treatment furnace with an oxygen flux of 10L / min During the sintering process, the oxygen content inside the furnace cavity is above 92%; the heating rate of the furnace body is 2°C / min, and the temperature is kept at a high temperature of 480°C for 12h; naturally cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com