Flotation method for improving beneficiation index of gold-bearing copper sulfide ore

A copper sulfide and ore technology, applied in flotation, process efficiency improvement, recycling technology and other directions, can solve the problems of corrosion equipment, poor floatability, poor quality of copper concentrate, etc., to improve quality and recovery rate , the effect of improving gold recovery rate and copper recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

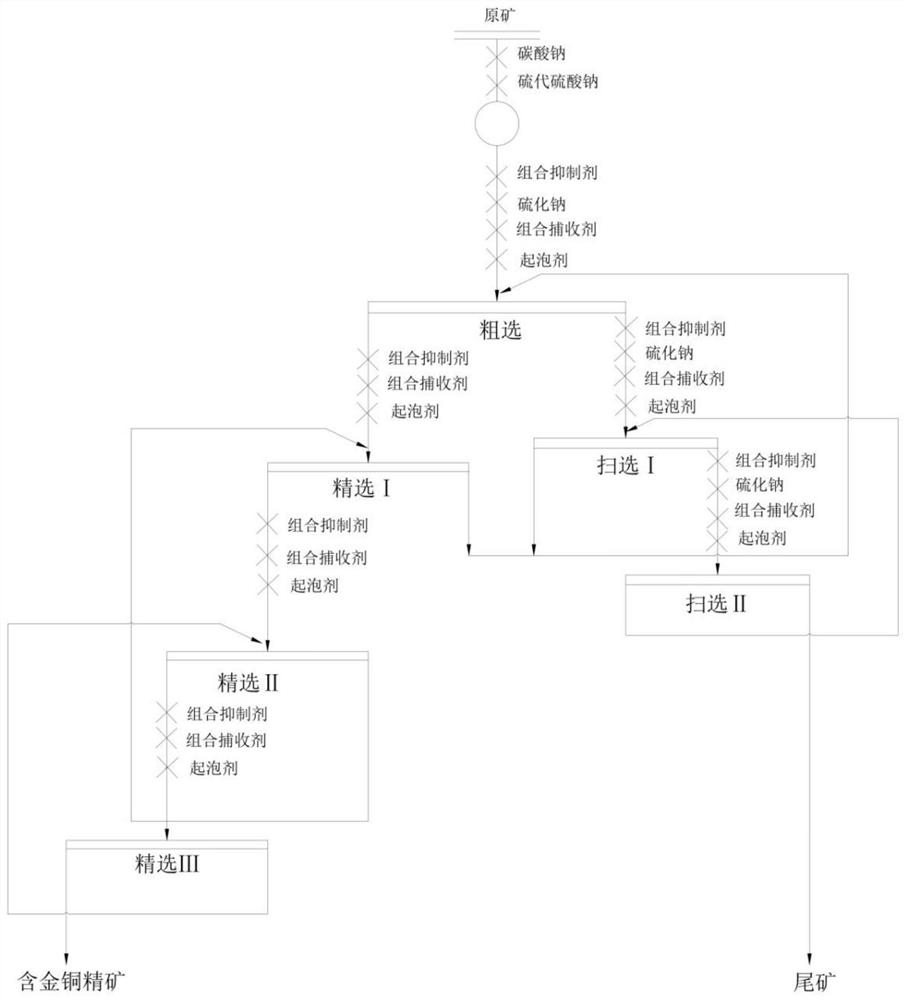

Image

Examples

Embodiment 1

[0038] The raw ore grades selected in this embodiment are copper 0.75%, sulfur 24.50%, iron 25.32%, and gold 0.28g / t. Its material composition is as follows: the main metal minerals in the ore are mainly pyrite and chalcopyrite, and the small and trace minerals are marcasite, bornite, chalcocite and blue chalcocite; the gangue minerals are pyroxene, Dolomite, quartz, calcite, feldspar, chlorite, epidote, etc. The phase analysis results of raw ore copper show that the copper minerals are mainly primary copper minerals (accounting for 92%), and chalcopyrite accounts for 95% of the primary copper minerals.

[0039] The combined inhibitor used in this example is obtained by mixing 45 parts of hydrogen peroxide and 65 parts of starch.

[0040] The combination collector used in this example is obtained by mixing 60 parts of collector Z-20000 and 40 parts of collector BK91640.

[0041] The specific beneficiation steps are as follows:

Embodiment 2

[0048] The raw ore grades selected in this embodiment are copper 0.58%, sulfur 22.50%, iron 23.32%, and gold 0.21g / t. Its material composition is as follows: the main metal minerals in the ore are pyrite and chalcopyrite, and the small and trace minerals are bornite, chalcocite and blue chalcocite; the gangue minerals are dolomite, quartz and calcite. The results of phase analysis of raw ore copper show that copper minerals include primary copper minerals and secondary copper minerals, with primary copper minerals as the main (accounting for 92%), chalcopyrite accounting for 95% of primary copper minerals, and copper oxide 2%.

[0049] The combined inhibitor used in this example is obtained by mixing 50 parts of hydrogen peroxide and 50 parts of starch.

[0050] The combined collector used in this example is obtained by mixing 50 parts of collector Z-20000 and collector BK91650 parts.

[0051] The specific beneficiation steps are as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com