Local porous silicon microneedle array and preparation method thereof

A microneedle array, porous silicon technology, applied in the field of silicon microneedles, achieves the effects of adjustable drug release, flexible drug loading, and large drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

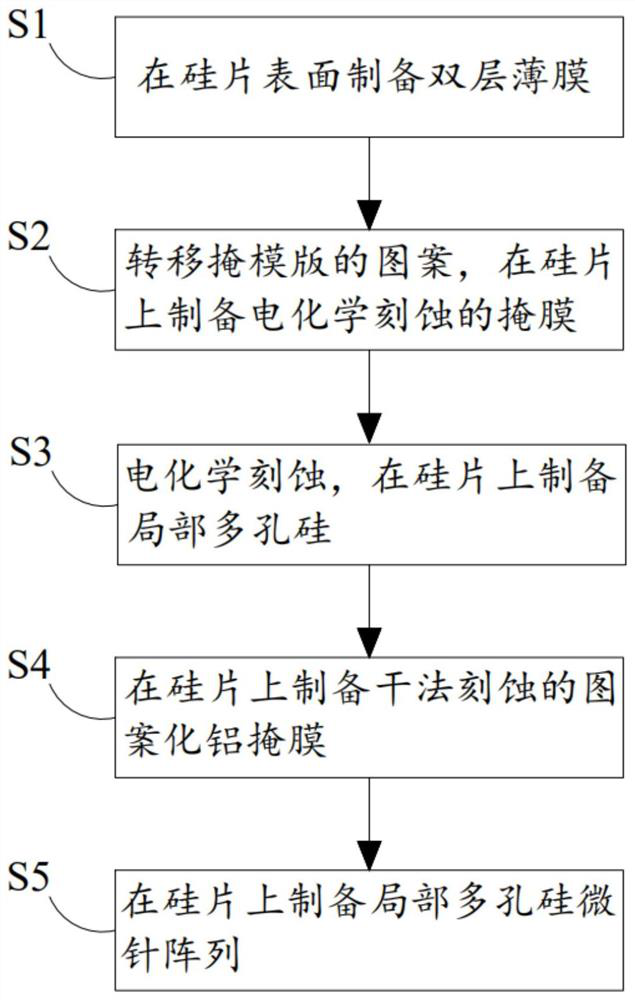

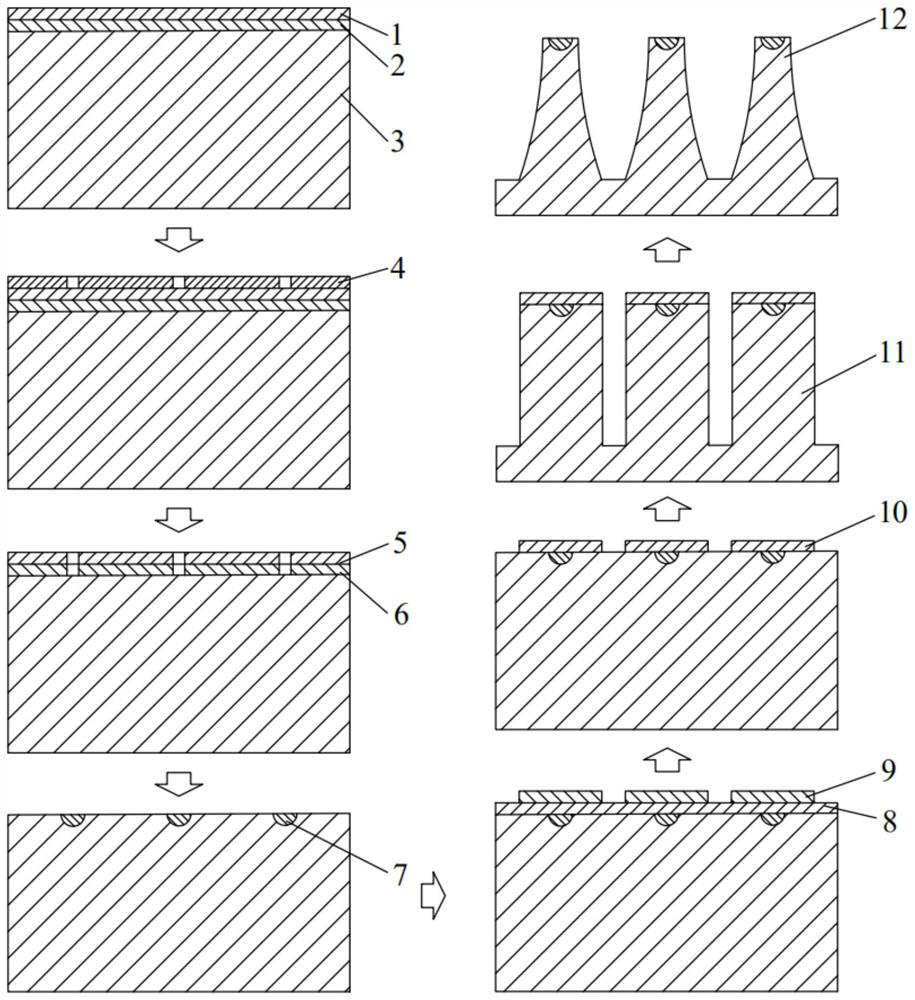

[0053] A method for preparing a partially porous silicon microneedle array, see figure 1 and combine figure 2 , Figure 4 shown. figure 2 The above is an array of 3 needles.

[0054] The preparation method of the local porous silicon microneedle array comprises the following steps:

[0055] Step S1, preparing a double-layer thin film on the surface of the silicon wafer, specifically includes the following steps:

[0056] 1.1. Put the P-type monocrystalline silicon wafer 3 with (100) crystal orientation, preferably with a thickness of 525 ± 25 μm, into a beaker filled with deionized water, ethanol and acetone in turn for ultrasonic cleaning to remove the silicon wafer surface. Impurities are dried and dehydrated, wherein the P-type single crystal silicon wafer is heavily doped, preferably, the resistance value is 0.01-0.02Ωcm.

[0057] 1.2. Submerge the above-mentioned silicon wafer in the first mixed solution for 3 minutes to prepare a hydrogen-terminated silicon (H-Si)...

Embodiment 2

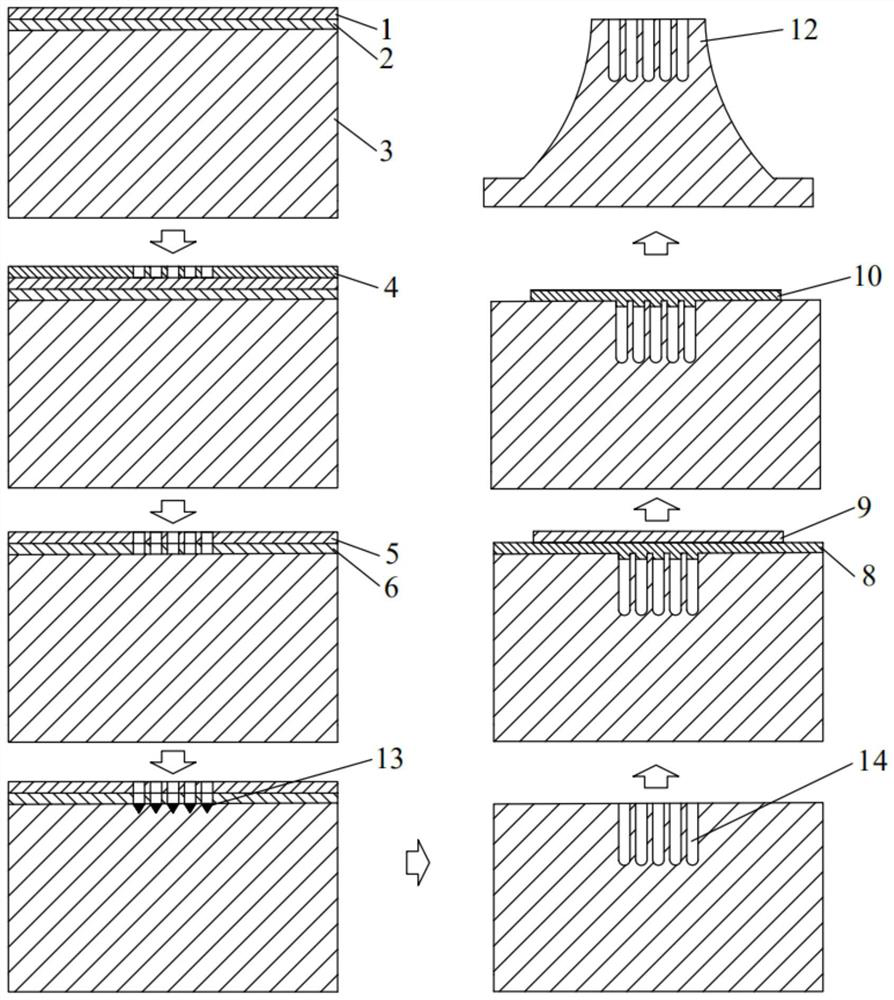

[0077] A method for preparing a locally porous silicon microneedle array. The difference in structure between this example 2 and the locally porous silicon microneedle array in Example 1 is that the locally porous silicon on the tip of the microneedle is composed of regular macroscopic pore array, and the partially porous silicon in Example 1 is mesoporous silicon, see figure 1 and combine image 3 , Figure 4 , Figure 5 shown. In order to more clearly show the local porous silicon microneedle structure in this embodiment, image 3 Only the preparation process and structure of a single partially porous silicon microneedle are expressed, but in fact the microneedles in this embodiment have an array structure.

[0078] The preparation method of the local porous silicon microneedle array in this embodiment comprises the following steps:

[0079] Step S1, preparing a double-layer thin film on the surface of the silicon wafer, specifically includes the following steps:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com