Method for eliminating white structure of high-purity pig iron for hydrogen-based smelting reduction casting and pig iron

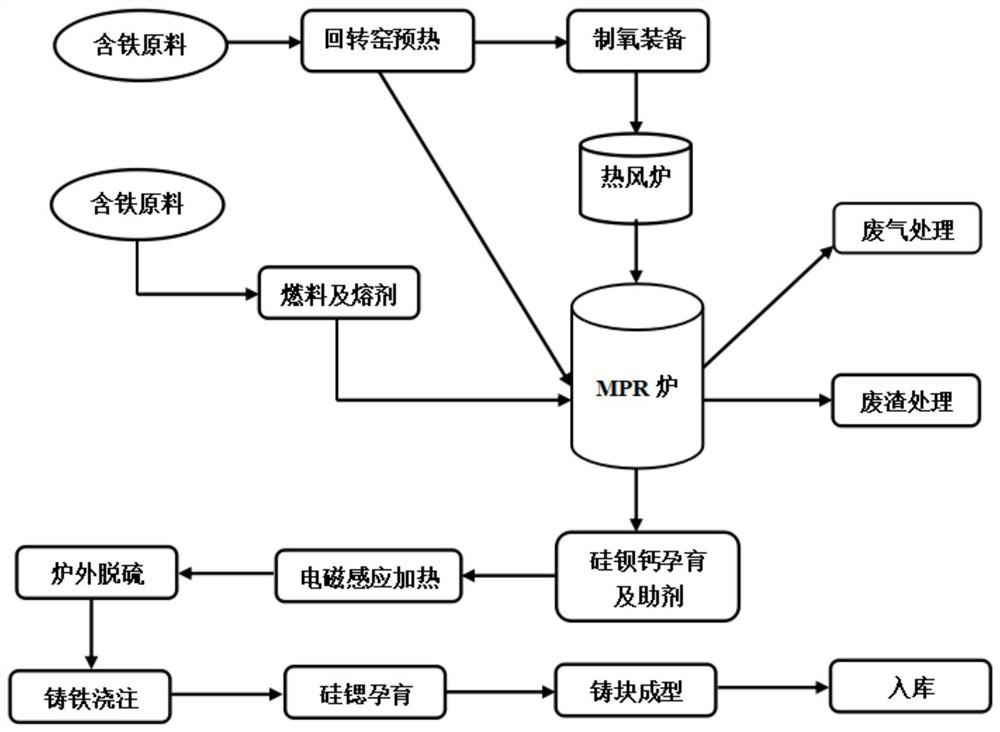

A high-purity pig iron, hydrogen-based technology, applied in the field of eliminating the white structure of high-purity pig iron for hydrogen-based smelting reduction casting, to achieve the effect of promoting carbon precipitation, promoting nucleation, and improving casting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Hydrogen-melting reduction smelting castings with high purity steel, when the height of the iron liquid level reaches 1850 mm, is prepared;

[0039] Then, the temperature was measured at 1405 ° C, and the main elements were shown in Table 1:

[0040] Table 1

[0041] element C Si Mn P S Ti content% 4.15 0.001 0.015 0.009 0.062 0.001

[0042] Chemical composition and particle size of silica matrix

[0043] Table 2

[0044] element Si BA CA granularity content% 67 5.2 2.5 3-10mm

[0045] The aidic zirconium silicon chemical composition and particle size:

[0046] table 3

[0047] element Zr Si FE granularity content% 36 49 margin 3-10mm

[0048] Chemical composition and particle size of strontium silicon gem

[0049] Table 4

[0050] element Sr Si FE granularity content% 0.85 75 margin 0.3-0.7mm

[0051] According to the chemical composition of silicate calcium in Table 2, ...

Embodiment 2

[0061] Hydrogen-melting reduction smelting castings with high purity steel, when the height of the iron liquid level reaches 1850 mm, is prepared;

[0062] Then, the temperature was measured at 1398 ° C, and the main elements were shown in Table 6:

[0063] Table 6

[0064] element C Si Mn P S Ti content% 4.21 0.001 0.019 0.011 0.069 0.001

[0065] Chemical composition and particle size of silica matrix

[0066] Table 7

[0067] element Si BA CA granularity content% 62 4.2 3.1 3-10mm

[0068] The aidic zirconium silicon chemical composition and particle size:

[0069] Table 8

[0070] element Zr Si FE granularity content% 35.5 46 margin 3-10mm

[0071] Chemical composition and particle size of strontium silicon gem

[0072] Table 9

[0073] element Sr Si FE granularity content% 0.72 76.2 margin 0.3-0.7mm

[0074] According to the chemical composition of silicate calcium in Table...

Embodiment 3

[0084] Hydrogen-melting reduction smelting castings with high purity steel, when the height of the iron liquid level reaches 1850 mm, is prepared;

[0085] Then, the temperature was measured on the raw iron ferrite, the temperature was 1421 ° C, and chemical analysis was carried out. The main elements were shown in Table 11:

[0086] Table 11

[0087] element C Si Mn P S Ti content% 3.92 0.001 0.021 0.015 0.058 0.001

[0088] Chemical composition and particle size of silica matrix

[0089] Table 12

[0090] element Si BA CA granularity content% 65 4.9 3.1 3-10mm

[0091] The aidic zirconium silicon chemical composition and particle size:

[0092] Table 13

[0093] element Zr Si FE granularity content% 37 47 margin 3-10mm

[0094] Chemical composition and particle size of strontium silicon gem

[0095] Table 14

[0096] element Sr Si FE granularity content% 1.05 77 margin 0.3-0.7mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com