A Casting Process of High Strength and High Toughness Ductile Iron

A technology of ductile cast iron and casting process, which is applied in the field of casting process of high-strength and high-toughness ductile iron, can solve the problems of complex casting process, high production cost, low molding efficiency, etc. drop, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

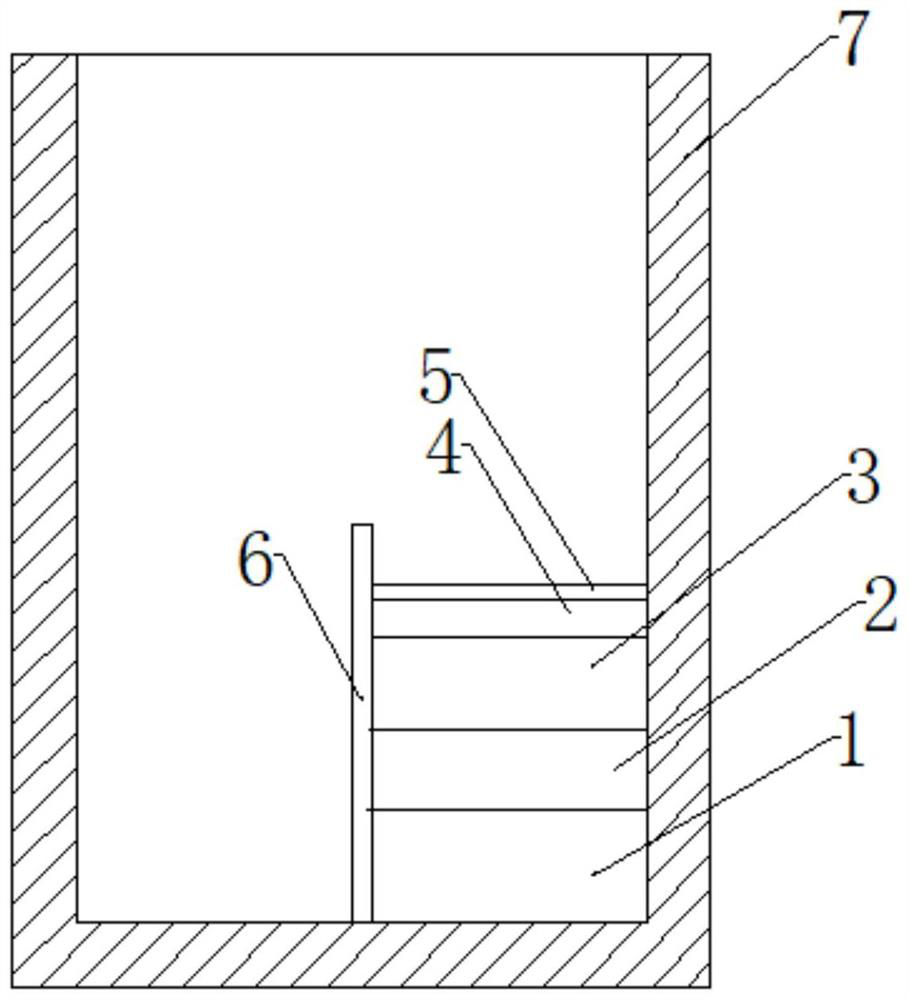

Image

Examples

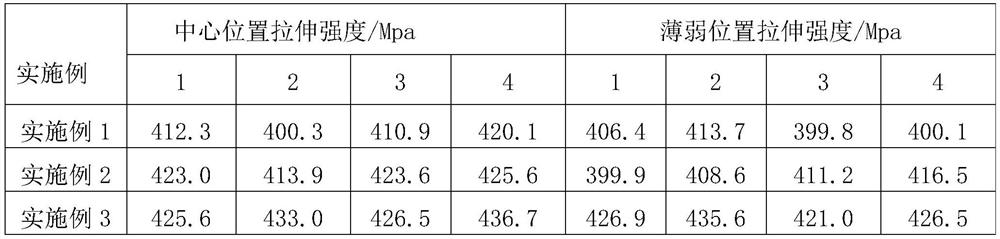

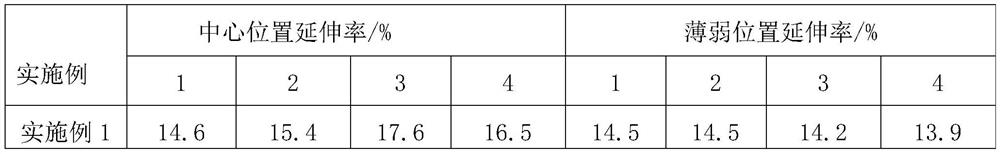

Embodiment 1

[0045] Preliminary preparation: conduct a comprehensive and detailed inspection of all equipment to confirm that there is no abnormality in the equipment;

[0046] Raw material preparation: the raw materials include pig iron, steel scrap, recycled material, pretreatment agent, Sb, carburizer, nodulizer, inoculant, and the inoculant includes inoculant in the bag and iron inoculant;

[0047] Wherein, the pretreatment agent is composed of the following components in terms of mass fraction: Si62%, Zr5%, Al5%, Ca1.5%, and the balance is Fe; the carburizer is composed of The following components are composed: C99.5%, the balance is S; the nodulizer, by mass fraction, is composed of the following components: Si45%, Mg6%, Ca1.2%, Re1.0%, Al1. 0%, Ba0.2%, Pb0.2%, Cu0.1%, Ni0.1%, the balance is Fe, the Re includes Ce, Nd, Y, and the Ce:Nd:Y=2:1: 1. The inoculant in the bag is composed of the following components by mass fraction: Si75%, Ca1.0%, Al1%, Ba2.5%, and the balance is Fe; the ...

Embodiment 2

[0055] Preliminary preparation: conduct a comprehensive and detailed inspection of all equipment to confirm that there is no abnormality in the equipment;

[0056] Raw material preparation: the raw materials include pig iron, steel scrap, recycled material, pretreatment agent, Sb, carburizer, nodulizer, inoculant, and the inoculant includes inoculant in the bag and iron inoculant;

[0057] Wherein, the pretreatment agent, in terms of mass fraction, is composed of the following components: Si65%, Zr5%, Al5%, Ca1.0%, and the balance is Fe; the carburizer, in mass fraction, consists of The following components are composed: C99.5%, the balance is S; the nodulizer, by mass fraction, is composed of the following components: Si45%, Mg5%, Ca1.0%, Re1, Al1.0%, Ba0.3%, Pb0.25%, Cu0.2%, Ni0.1%, the balance is Fe, the Re includes Ce, Nd, Y, and the Ce:Nd:Y=2:1:1; The inoculant in the bag, by mass fraction, is composed of the following components: Si72%, Ca1.0%, Al1%, Ba2.0%, and the bal...

Embodiment 3

[0065] Preliminary preparation: conduct a comprehensive and detailed inspection of all equipment to confirm that there is no abnormality in the equipment;

[0066] Raw material preparation: the raw materials include pig iron, steel scrap, recycled material, pretreatment agent, Sb, carburizer, nodulizer, inoculant, and the inoculant includes inoculant in the bag and iron inoculant;

[0067] Wherein, the pretreatment agent is composed of the following components in terms of mass fraction: Si62%, Zr5%, Al3%, Ca1.5%, and the balance is Fe; the carburizer is composed of The following components are composed: C99.5%, the balance is S; the nodulizer, by mass fraction, is composed of the following components: Si44%, Mg6%, Ca1%, Re1%, Al0.5%, Ba0 .2%, Pb0.2%, Cu0.1%, Ni0.1%, the balance is Fe, the Re includes Ce, Nd, Y, the Ce:Nd:Y=2:1:1; The inoculant in the bag is composed of the following components by mass fraction: Si74%, Ca2%, Al1%, Ba2.0%, and the balance is Fe; the iron inocul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com