A heat treatment method for railway wagon axles

A process method and technology of railway wagons, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems that the sound transmission performance of axles cannot meet the requirements, and achieve the effect of improving sound transmission performance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a heat treatment process for railway freight car axles. The relationship between the carbon content of the axle and the process parameters of each step of heat treatment is shown in Table 1.

[0029] Table 1

[0030]

[0031] Among them, ±10°C in each temperature parameter is the heating accuracy of the heating furnace in the heat treatment process.

Embodiment 2

[0033] This embodiment provides a heat treatment process for railway freight car axles. The relationship between the carbon content of the axle and the process parameters of each step of heat treatment is shown in Table 2.

[0034] Table 2

[0035]

[0036] Among them, ±10°C in each temperature parameter is the heating accuracy of the heating furnace in the heat treatment process.

Embodiment 3

[0038] This embodiment provides a heat treatment process for railway freight car axles. The relationship between the carbon content of the axle and the process parameters of each heat treatment step is shown in Table 3.

[0039] table 3

[0040]

[0041] Among them, ±10°C in each temperature parameter is the heating accuracy of the heating furnace in the heat treatment process.

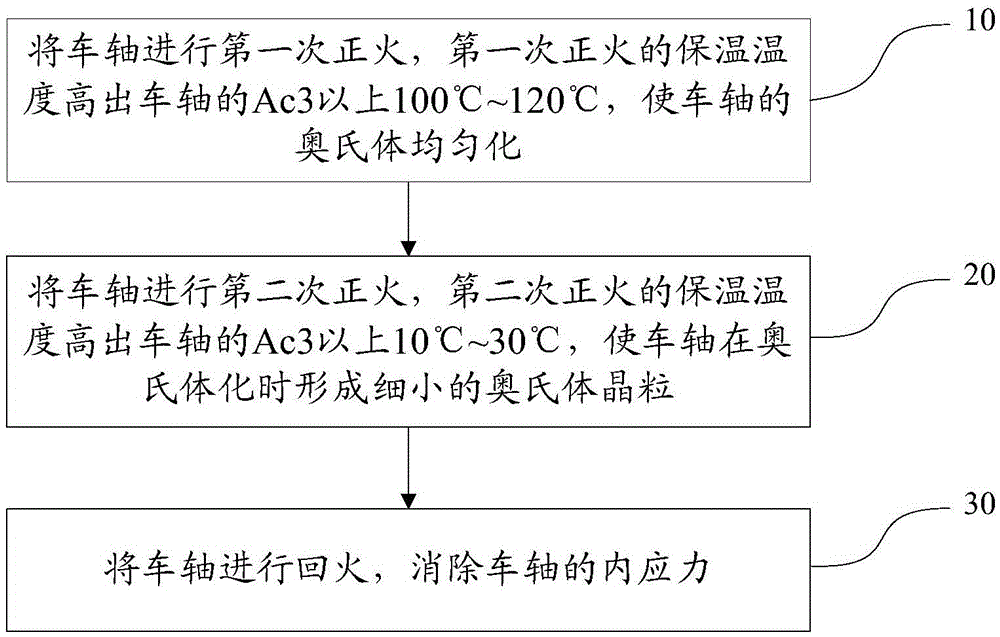

[0042] From the axle heat treatment process introduced in the above examples, it can be seen that the axle has been normalized twice and tempered once during the heat treatment process. The holding temperature of the two normalizings is different, and its purpose and function are also different. The temperature of the first normalizing is high, 100-120°C higher than Ac3, and its main function is to homogenize the austenite of the axle, obtain a uniform structure, and prepare for the second normalizing. The temperature of the second normalizing is low, 10-30°C higher than Ac3, so that when the axle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com