Quenching cooling method for bainite steel frog point rail

A technology of bainitic steel and a cooling method, which is applied in the field of quenching and cooling of bainitic steel frog core rails, can solve the problems of inability to industrialize, large-scale deformation prevention, single quick cooling adjustment method, and small adjustment range, etc. The effect of uniform performance index, small deformation and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

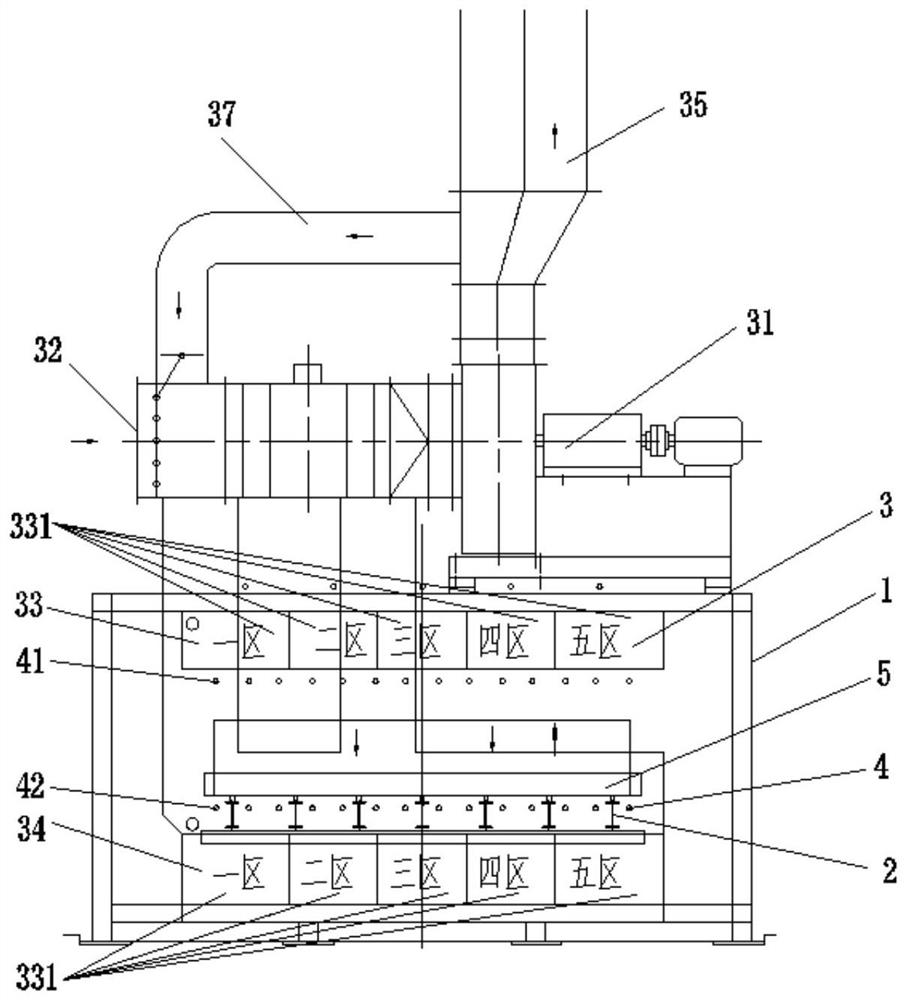

[0051] A method for quenching and cooling a bainite steel frog core rail, comprising the following steps:

[0052] S001, the furnace door 6 of the quenching and rapid cooling chamber is opened; the reclaimer places the core rails that need to be rapidly cooled at a fixed distance before on the support 2; the furnace door 6 of the quenching and rapid cooling chamber is closed.

[0053] S002. Manually click the start button, and the quenching rapid cooling chamber starts to execute the rapid cooling procedure.

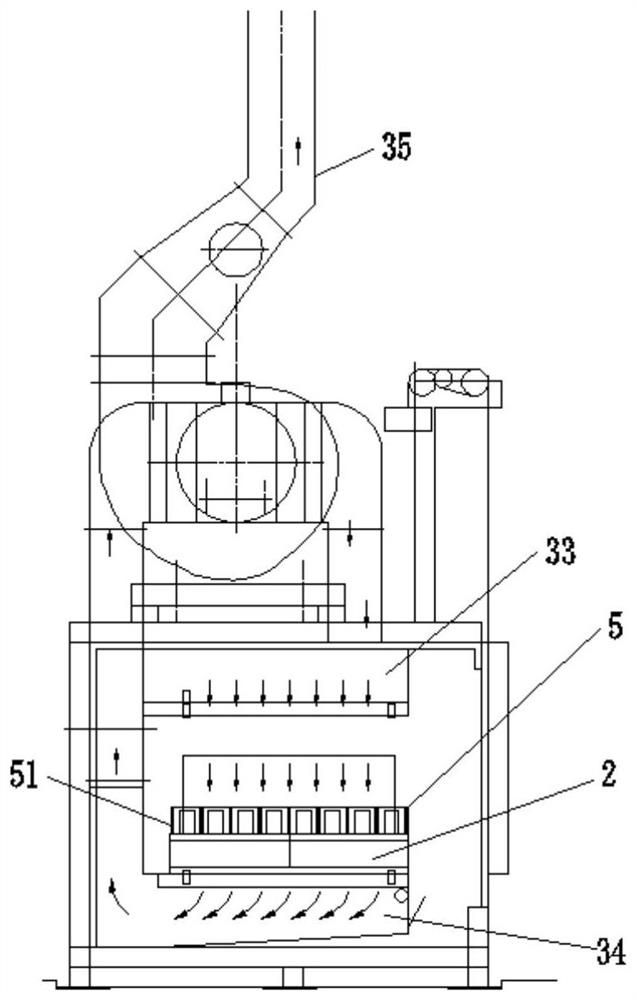

[0054] S003. In the 920-650°C high-temperature cooling stage in the rapid cooling program, in the quenching rapid cooling chamber, combine the air cooling device 3 with the reversing function and partition function with the non-contact water cooling heat exchange device 5 to perform cooling on the frog core rail. Cool down.

[0055] In step S003, further: the centrifugal fan 31 used by the air cooling device 3 rotates at 1400 rpm, and blows air at the maximum rated spee...

Embodiment 2

[0070] A method for quenching and cooling a bainite steel frog core rail, comprising the following steps:

[0071] S001, the furnace door 6 of the quenching and rapid cooling chamber is opened; the reclaimer places the core rails that need to be rapidly cooled at a fixed distance before on the support 2; the furnace door 6 of the quenching and rapid cooling chamber is closed.

[0072] S002. Manually click the start button, and the quenching rapid cooling chamber starts to execute the rapid cooling procedure.

[0073] S003. In the 920-650°C high-temperature cooling stage in the rapid cooling program, in the quenching rapid cooling chamber, combine the air cooling device 3 with the reversing function and partition function with the non-contact water cooling heat exchange device 5 to perform cooling on the frog core rail. Cool down.

[0074] In step S003, further: the centrifugal fan 31 used by the air cooling device 3 rotates at 1400 rpm, and blows air at the maximum rated spee...

Embodiment 3

[0082] A method for quenching and cooling a bainite steel frog core rail, comprising the following steps:

[0083] S001, the furnace door 6 of the quenching and rapid cooling chamber is opened; the reclaimer places the core rails that need to be rapidly cooled at a fixed distance before on the support 2; the furnace door 6 of the quenching and rapid cooling chamber is closed.

[0084] S002. Manually click the start button, and the quenching rapid cooling chamber starts to execute the rapid cooling procedure.

[0085] S003. In the 920-650°C high-temperature cooling stage in the rapid cooling program, in the quenching rapid cooling chamber, combine the air cooling device 3 with the reversing function and partition function with the non-contact water cooling heat exchange device 5 to perform cooling on the frog core rail. Cool down.

[0086] In step S003, further: the centrifugal fan 31 used by the air cooling device 3 rotates at 1400 rpm, and blows air at the maximum rated spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com