Sand-carrying fiber and preparation and application thereof

A technology of sand fiber and fibrin glue, which is applied in the field of composite nanomaterials and oil exploration technology research, can solve the problems of delayed solubility, sand carrying and easy flowback performance, etc., and achieve low risk of fracture blockage and high conductivity Strong, good toughness and solubility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

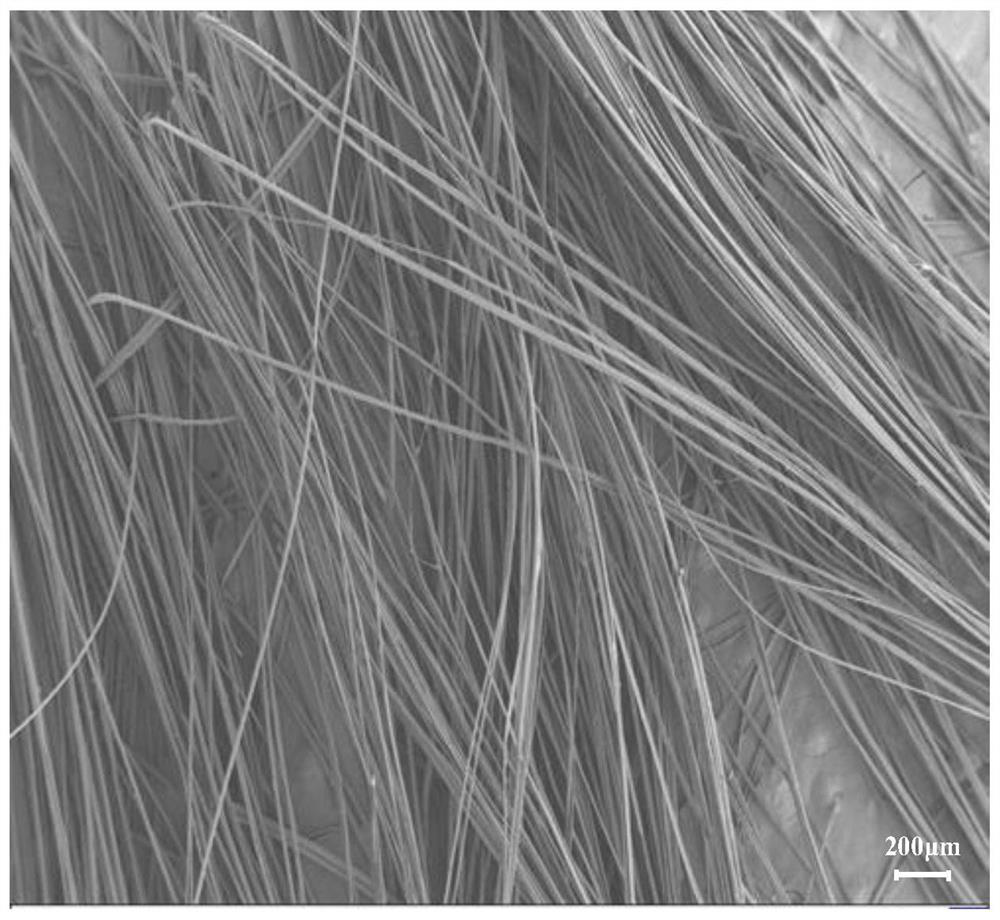

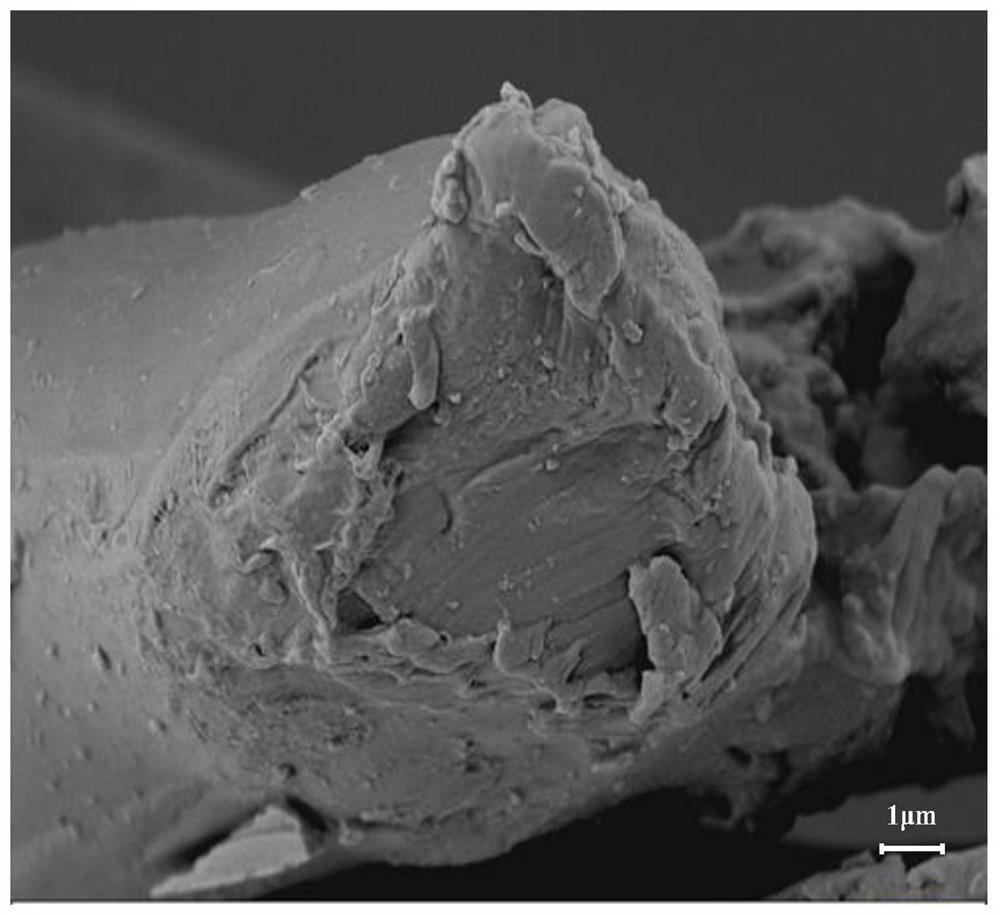

[0056] This embodiment prepares a kind of sand-carrying fiber, comprises the following steps:

[0057] 100 parts of polylactic acid, 15 parts of poly-p-phenylene terephthalamide, 3 parts of sodium dodecylbenzenesulfonate, 3 parts of citric acid, 16 parts of polyvinyl alcohol, 11 parts of glyceryl monostearate, 16 parts of polyethylene glycol, 8 parts of magnesium phosphate-fibrin glue, and 2 parts of zinc chloride were stirred at 1500 r / min for 30 minutes to obtain a uniform mixed solution.

[0058] Among them, the relative molecular weight of polylactic acid polylactic acid is 110,000, the relative molecular weight of polyvinyl alcohol is 27,000, and the relative molecular weight of polyparaphenylene terephthalamide is 55,000.

[0059] The prepared polylactic acid mixture is screw extruded and melted at 200°C, and the melted mixture is extruded into a thin stream of melt through the electrospinning equipment, and the melted mixture is extruded into a thin stream of melt throu...

Embodiment 2

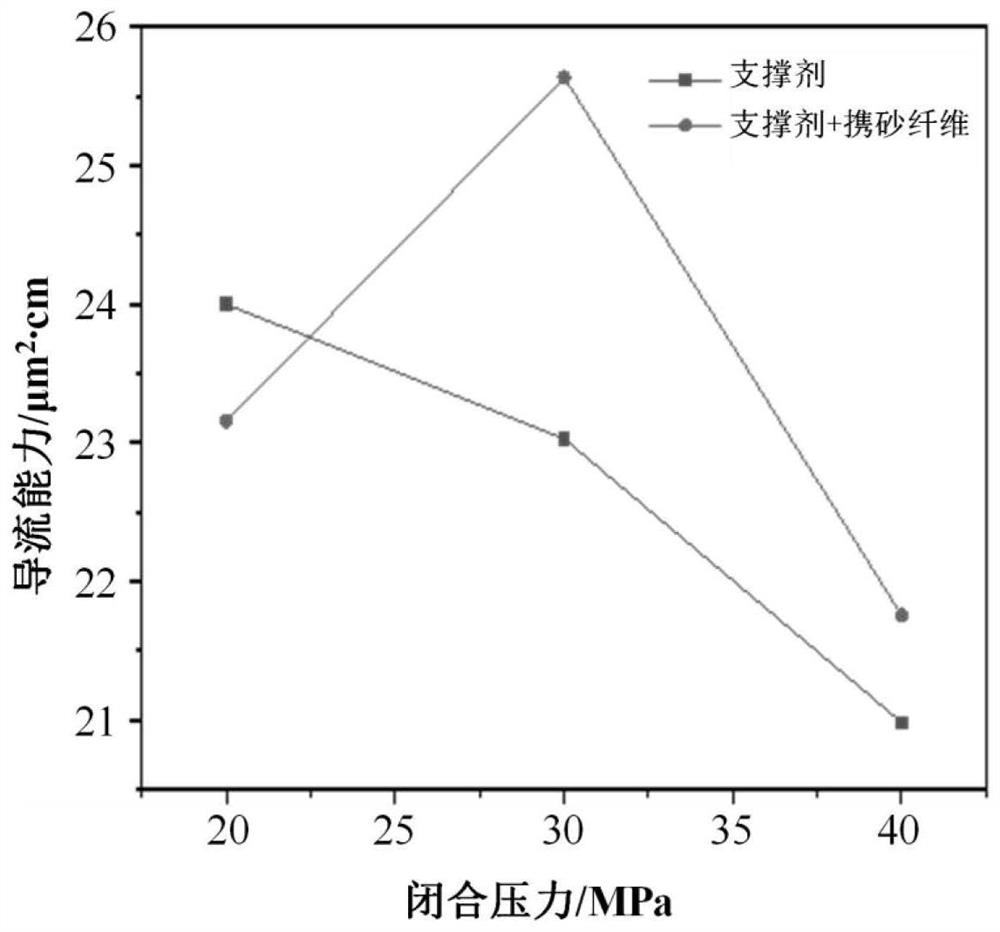

[0062] In this example, the sand-carrying fiber prepared in Example 1 is tested to simulate the influence of the sand-carrying fiber on the proppant conductivity during the fracturing of the oil well reservoir, so as to understand the fractures supported by the sand-carrying fiber in the formation, The relationship between its conductivity and the change of closing pressure.

[0063] The samples were divided into experimental group and control group. In the experimental group, the sand-carrying fiber and 5g proppant (ceramsite) were paved in a single layer on the rock surface covered with copper wire mesh to keep the proppant and sand-carrying fiber dispersed evenly and tightly. . In the control group, only 5g of proppant was spread in a single layer on the rock surface covered with copper wire mesh. Turn on the diversion instrument and apply different pressure loads to obtain the diversion capacity values of the experimental group and the control group under different pres...

Embodiment 3

[0066] In this example, the sand-carrying fiber prepared in Example 1 is tested to examine the influence of the sand-carrying fiber on the suspending capacity of the proppant during the fracturing process of the oil well reservoir.

[0067] Measure 1500mL of deionized water into a beaker, slowly add 4.5g of guar gum, stir at room temperature for 4 hours, and adjust the stirring speed to 1500r / min. The prepared base solution was divided into ten portions, each with 100mL in beakers. Add 50mg, 100mg, 150mg, 200mg, 225mg, 250mg, 300mg, 350mg, 400mg and 500mg of the soluble sand-carrying fiber prepared in Example 1, respectively, and prepare a copy as a blank control. Then add 1g of proppant (ceramsite) respectively, and observe the relative suspended sand performance after 1h.

[0068] image 3 For the test results of the different quality sand-carrying fibers prepared by Example 1 of the present invention to the relative suspension performance of the proppant, image 3 It sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com