Fire disaster low-altitude flight rescue unmanned aerial vehicle fuselage light material surface coating and preparation method thereof

A lightweight material, low-altitude flight technology, applied in metal material coating process, coating, fuselage and other directions, can solve the problems of low melting point, insufficient high temperature resistance, and poor corrosion resistance of resin-based composite materials, and achieve improved Oxidation resistance, oxidation loss prevention, thermal stress reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

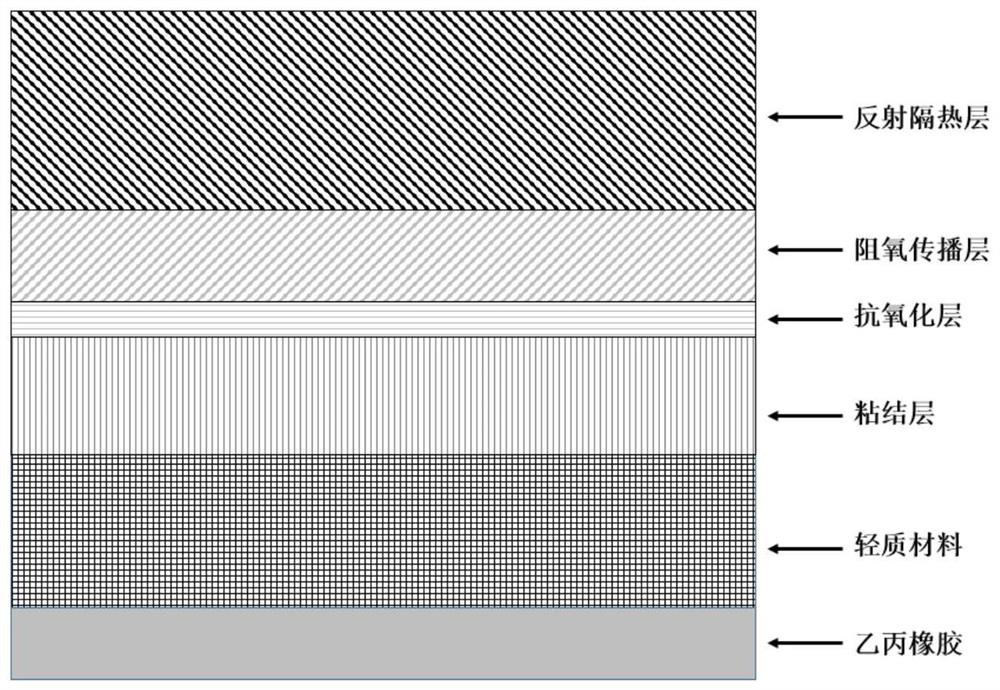

[0046] A low-altitude flight rescue UAV fuselage lightweight material surface coating, the UAV fuselage is made of lightweight materials and the lightweight materials are selected from at least carbon fiber braids, titanium alloys and aluminum alloys A: The surface of the lightweight material is coated with a coating, and the coating is composed of a bonding layer, an anti-oxidation layer, an oxygen barrier propagation layer and a reflective heat insulation layer. The surface of the material is sequentially prepared to form a bonding layer, an anti-oxidation layer, an oxygen barrier propagation layer, and a reflective heat insulation layer. The specific steps are as follows:

[0047] (1) Select a material with a thermal expansion coefficient similar to that of the lightweight material, and form a bonding layer on the surface of the lightweight material by electron beam physical vapor deposition;

[0048] (2) Place the bonding layer in the air for heating and oxidation, so that...

Embodiment 1

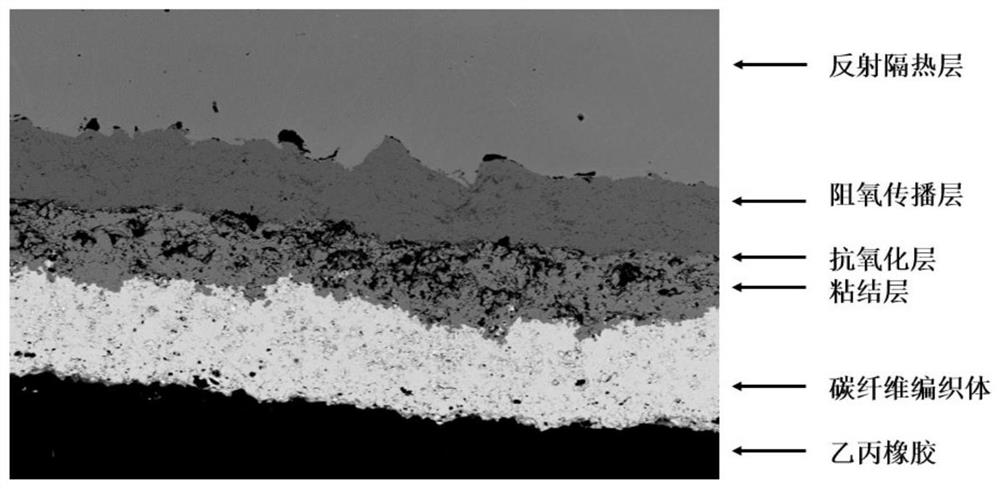

[0068] In this example, the carbon fiber braided body material is used as the substrate, and a coating composed of "bonding layer + anti-oxidation layer + oxygen barrier transmission layer + reflective heat insulation layer" is prepared on the surface of the substrate. The specific steps are as follows:

[0069] (1) Prepare a silicon (Si) bonding layer with a thickness of 50 microns on the surface of the carbon fiber braid by means of electron beam physical vapor deposition. °, the acceleration voltage of electrons is 20kV, and the vacuum degree is lower than 2×10 -3 Pa, the deposition rate is 100nm / min.

[0070] (2) After the Si coating is prepared, it is placed in the air and heated at 300°C for oxidation to obtain SiO with a thickness of 10 microns. 2 Coating, that is, the anti-oxidation layer.

[0071] (3) Prepare an oxygen barrier propagation layer with a thickness of 50 microns on the surface of the anti-oxidation layer by atmospheric plasma spraying——YbTaO 4 Ceramic ...

Embodiment 2

[0076] In this example, the TC4 titanium alloy material is used as the substrate, and a coating composed of "adhesive layer + anti-oxidation layer + oxygen barrier transmission layer + reflective heat insulation layer" is prepared on the surface of the substrate. The specific steps are as follows:

[0077] (1) An aluminum (Al) bonding layer with a thickness of 50 microns was prepared on the surface of TC4 titanium alloy by electron beam physical vapor deposition. °, the accelerating voltage of electrons is 22kV, and the vacuum degree is lower than 3×10 -3 Pa, the deposition rate is 100nm / min.

[0078] (2) After the Al coating is prepared, it is placed in the air and heated at 100°C for oxidation to obtain Al with a thickness of less than 10 microns. 2 o 3 Coating, that is, the anti-oxidation layer.

[0079] (3) Prepare an oxygen barrier propagation layer with a thickness of 50 microns on the surface of the anti-oxidation layer by atmospheric plasma spraying——AlTaO 4 Cerami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com