Aluminum-containing low-carbon steel and preparation process

A preparation process and low-carbon steel technology, which is applied in the field of iron and steel smelting, can solve the problems of continuous casting machine shutdown, inclusions, nozzle flocculation, etc., and achieve the effects of improving purity, improving the purity of molten steel, good plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

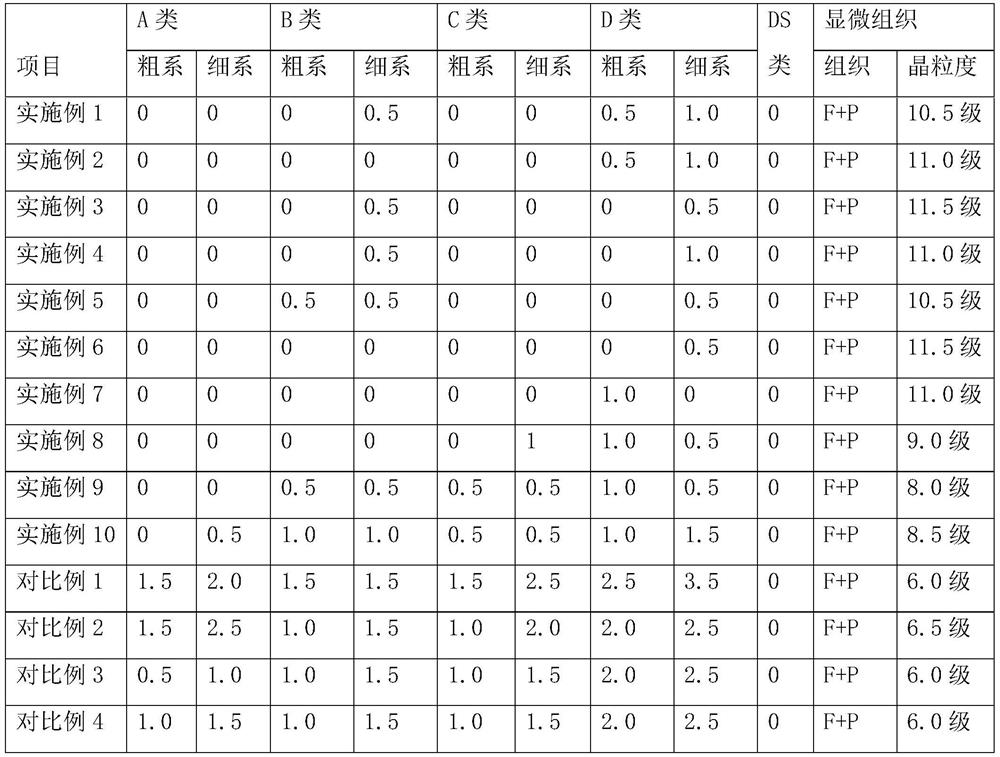

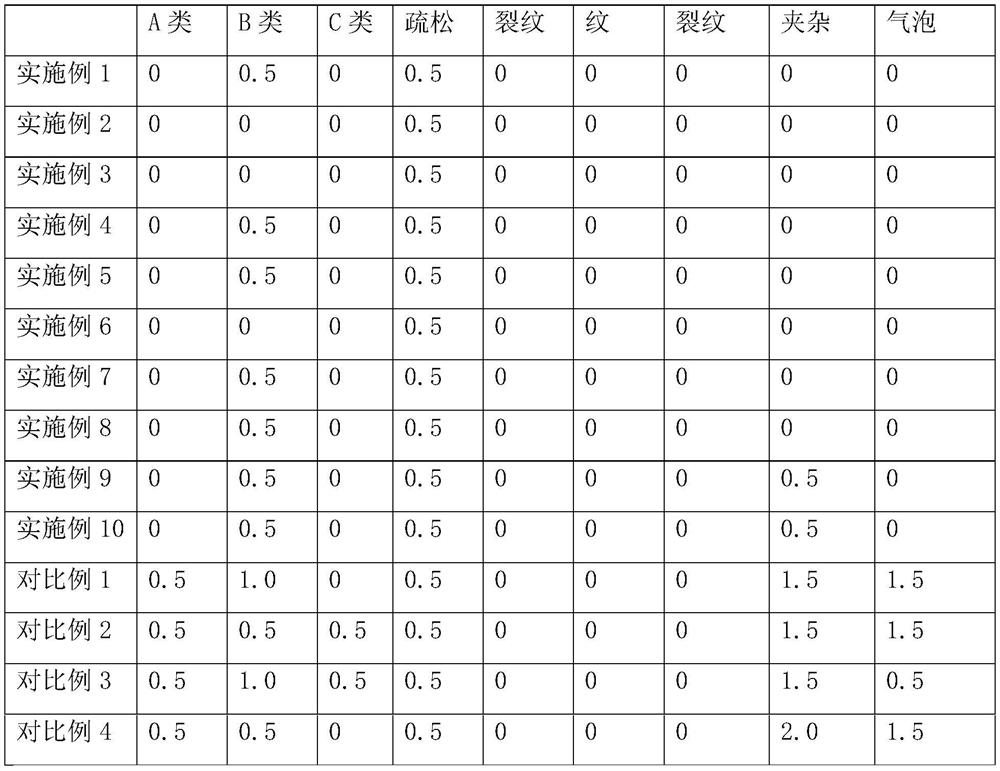

Examples

Embodiment 1

[0037] A production process of aluminum-containing low-carbon steel, comprising the steps of:

[0038] (1) Primary smelting of converter

[0039] (11) First add molten iron to the converter, the temperature of the molten iron entering the furnace is 1350°C, in terms of mass percentage, P0.145% and S0.050% in the molten iron, then add scrap steel to the molten iron, the total charge of molten iron and scrap steel 125t, of which scrap steel is 30t; afterward, blowing is carried out by top-bottom combined blowing for 12min, top-blowing oxygen pressure is 0.6MPa, oxygen lance flow rate is 30000Nm 3 / h, blow nitrogen 5 minutes before bottom blowing, then switch to bottom blowing argon, the flow rate of nitrogen and argon is 40Nm 3 / h, the pressure is 0.5MPa, add 3.75t of limestone and 0.875t of dolomite at the beginning of blowing, control the basicity of slag to 2.8, continue blowing and control the end point composition of converter molten steel: C 0.07%, P 0.030%, S 0.035 %, the...

Embodiment 2

[0052] A production process of aluminum-containing low-carbon steel, comprising the steps of:

[0053] (1) Primary smelting of converter

[0054] (11) First add molten iron to the converter, the temperature of the molten iron entering the furnace is 1340°C, in terms of mass percentage, P0.146% and S 0.042% in the molten iron, then add scrap steel to the molten iron, the total charge of molten iron and scrap steel 120t, of which scrap steel is 30t; afterward blowing is carried out for 15min by top-bottom combined blowing, top-blowing oxygen pressure is 0.5MPa, oxygen lance flow rate is 25000Nm 3 / h, nitrogen blowing 10 minutes before bottom blowing, then switch to bottom blowing argon, nitrogen and argon flow are both 50N m 3 / h, the pressure is 0.6MPa, add 3.96t of limestone and 0.6t of dolomite during blowing, control the basicity of slag to 3.1; continue blowing to control the end point composition of molten steel: C0.06%, P 0.030%, S 0.035% , the balance is Fe;

[0055] ...

Embodiment 3

[0067] A production process of aluminum-containing low-carbon steel, comprising the steps of:

[0068] (1) Primary smelting of converter

[0069] (11) First add molten iron to the converter, the temperature of the molten iron entering the furnace is 1430°C, in terms of mass percentage, P0.145% and S0.040% in the molten iron, then add scrap steel to the molten iron, the total charge of molten iron and scrap steel 120t, of which scrap steel is 30t; afterward blowing is carried out by top-bottom combined blowing for 10min, top-blowing oxygen pressure is 1.0MPa, oxygen lance flow rate is 20000Nm 3 / h, nitrogen blowing 10 minutes before bottom blowing, then switch to bottom blowing argon, nitrogen and argon flow are both 45N m 3 / h, the pressure is 0.4MPa, add limestone 4.8t and dolomite 1.2t during blowing, control the basicity of slag to 3.5, continue blowing to control the end point composition of molten steel: C0.06%, P 0.028%, S 0.032% , the balance is Fe;

[0070] (12) Tap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com