Preparation method of master alloy for beryllium bronze based on electroslag smelting of beryllium bag powder waste

A technology of electroslag smelting and beryllium bronze, which is applied in the metallurgy field of metal materials, can solve problems such as environmental hazards, high beryllium content, and long process, and achieve the effects of reducing oxidation and burning loss, high metal yield, and excellent fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

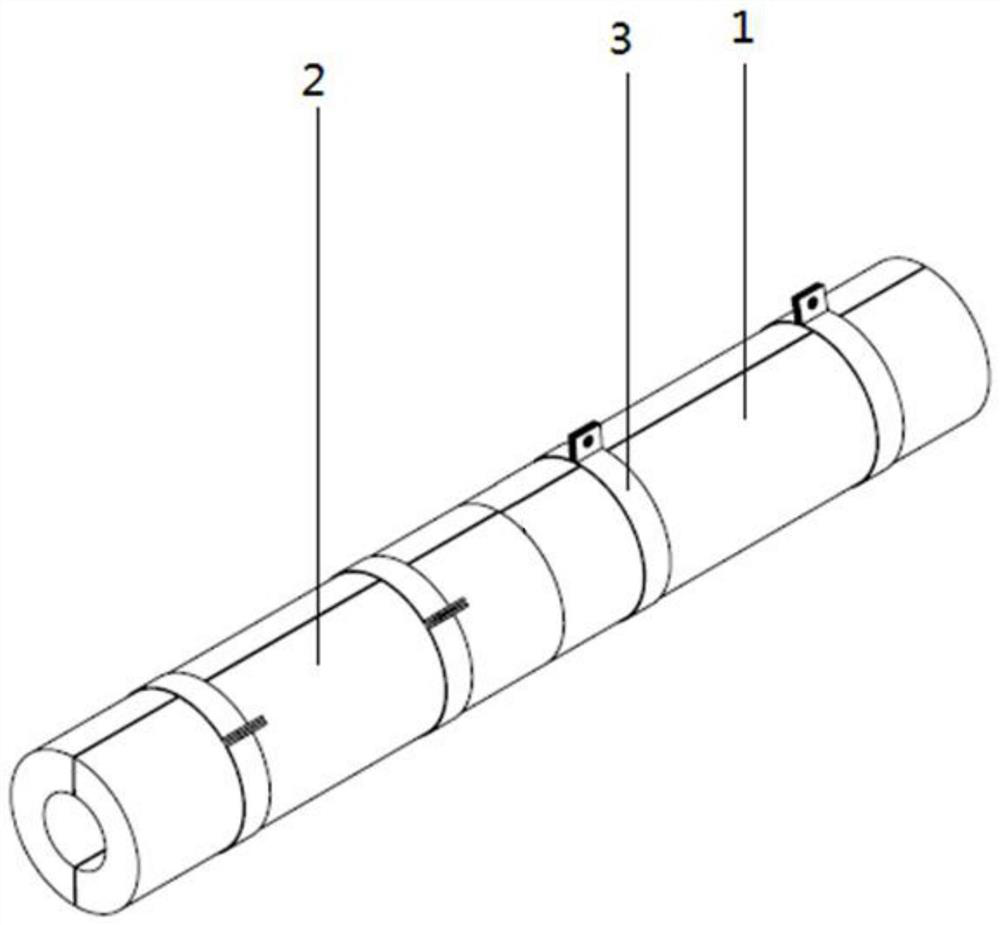

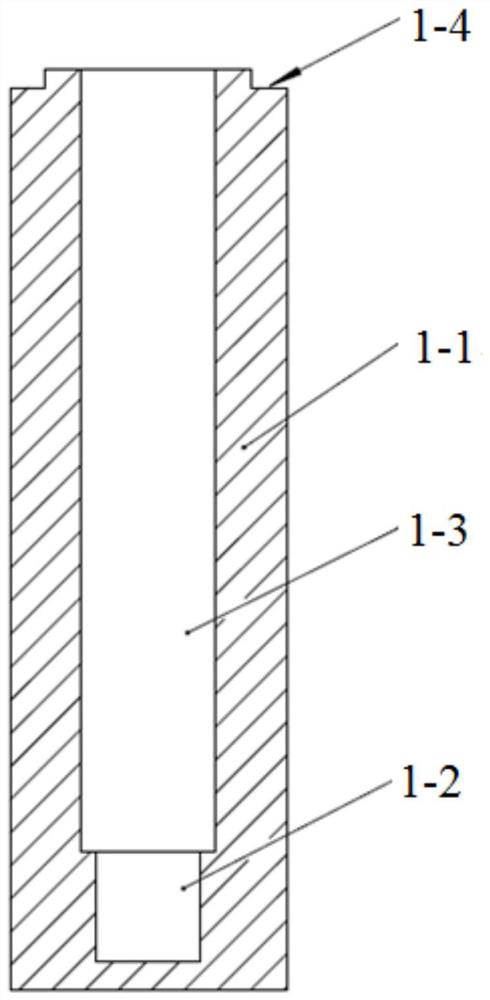

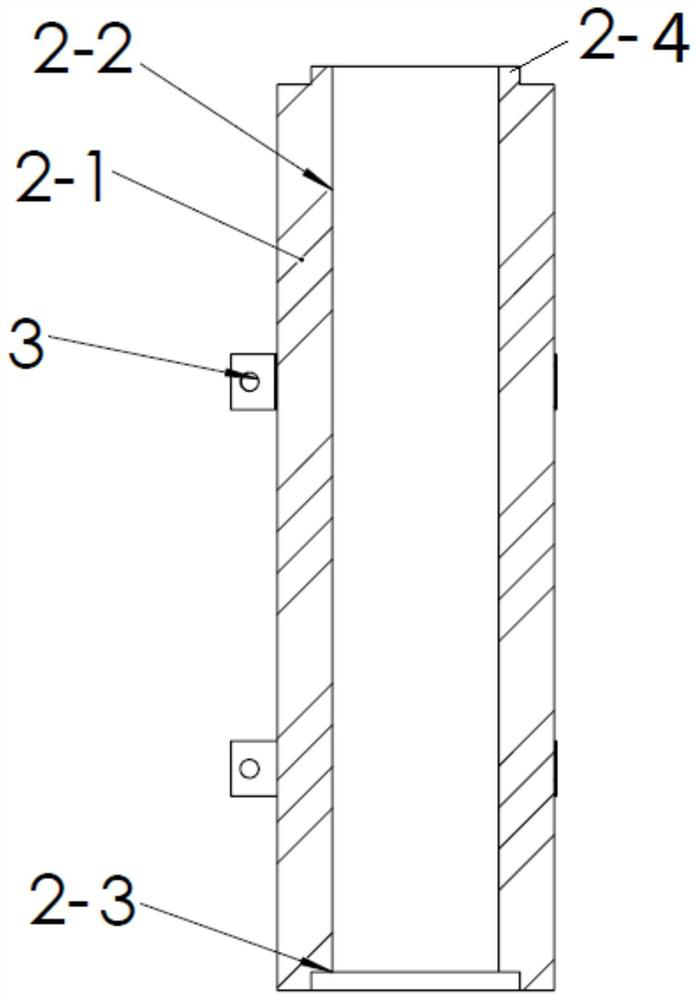

[0056] This embodiment provides a kind of preparation method of master alloy for beryllium bronze based on electroslag smelting of beryllium bag powder waste material, and this preparation method comprises the following steps:

[0057] Step 1: Mix the beryllium cloth bag powder waste and water evenly, and then carry out isostatic pressing molding and drying treatment sequentially to obtain multiple beryllium rods.

[0058] The beryllium bag powder waste is mixed with appropriate amount of water, pressed and formed by an isostatic pressing machine, and processed into a billet (ie beryllium rod) of Φ60-80×400mm, and then dried to remove water. The weight fraction of beryllium bag powder waste and water in this embodiment is 1:0.01-0.06, and the mixing time is 20-30 minutes. The pressure of isostatic pressing is 260-440MPa. The temperature of the drying treatment is 220-240° C., and the drying treatment time is 10.5-12.5 hours.

[0059] Step 2: Gradient heating of copper to 106...

Embodiment 1

[0094] 1. Weigh 8 kg of beryllium cloth bag powder waste, add 0.08 kg of water and mix for 20 minutes, press and form it under the pressure of 260 MPa by an isostatic pressing machine, and process it into 4 sections of Φ60×400 mm billet (ie, beryllium rod), and then heat it at 220 ° C, Dry under the condition of 10.5h to remove moisture.

[0095] 2. Weigh the dried bag powder sticks, and mix them into copper blocks according to the target beryllium content of 4.0% in the beryllium-copper master alloy.

[0096]3. Put the prepared red copper block into the induction furnace crucible and send electricity to carry out gradient heating: use 50KW power to heat up from room temperature to 200°C for 12 minutes; then use 80KW power to heat up from 200°C to 500°C for heat preservation 6 minutes; continue to use 100KW power, heat up from 500°C to 1060°C for 6 minutes; finally use 150KW power, heat up from 1060°C to 1180°C for 2 minutes and keep it for 2 minutes. After 2 minutes, pour th...

Embodiment 2

[0105] 1. Weigh 10 kg of beryllium cloth bag powder waste, add 0.6 kg of water and mix for 30 minutes, press and form it under the pressure of 440 MPa by an isostatic pressing machine, and process it into 4 sections of Φ80×400 mm billet (ie, beryllium rod), and then heat it at 240 ° C, Dry for 12.5 hours to remove moisture.

[0106] 2. Weigh the dried bag powder sticks, and mix them into copper blocks according to the target beryllium content of 4.2% in the beryllium-copper master alloy.

[0107] 3. Put the prepared electrolytic copper into the induction furnace crucible and then send electricity to carry out gradient heating: use 50KW power to heat up from room temperature to 200°C for 18 minutes; then use 80KW power to heat up from 200°C to 500°C for heat preservation 8 minutes; continue to use 100KW power, heat up from 500°C to 1060°C for 8 minutes; finally use 150KW power, heat up from 1060°C to 1180°C for 4 minutes and keep it for 4 minutes. After 3 minutes, pour the cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com