Photocatalyst as well as preparation method and application thereof

A technology of photocatalyst and reactor, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of complex preparation process, limited potential, high cost, etc. Achieve high-efficiency photocatalytic degradation, promote separation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

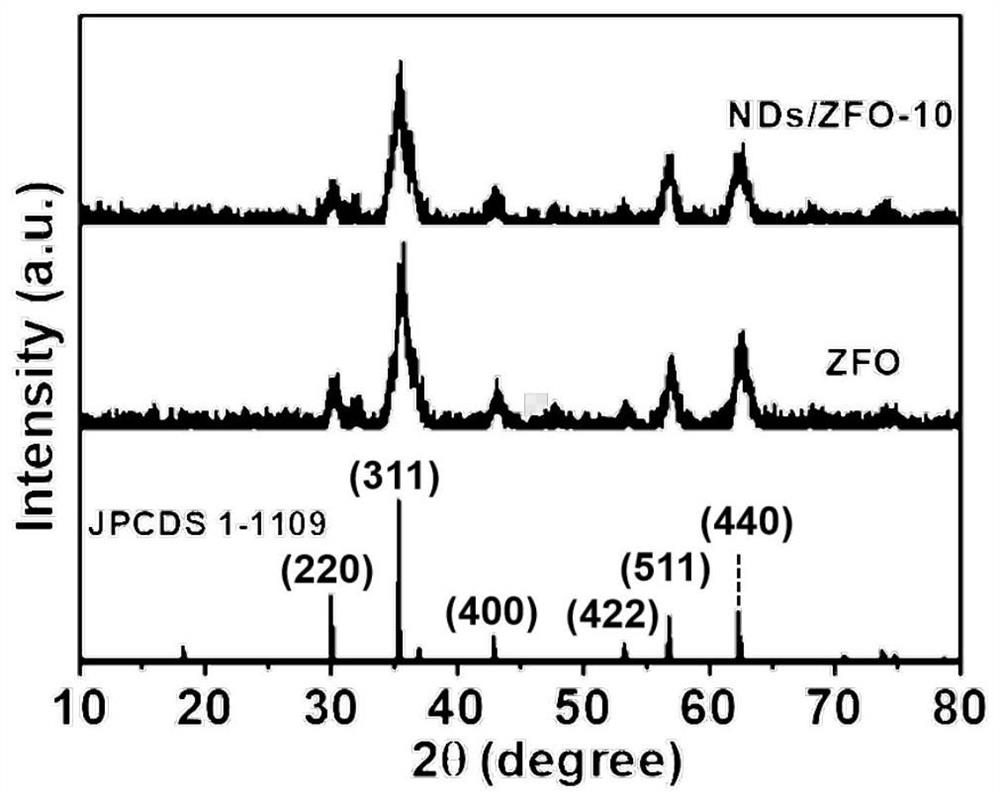

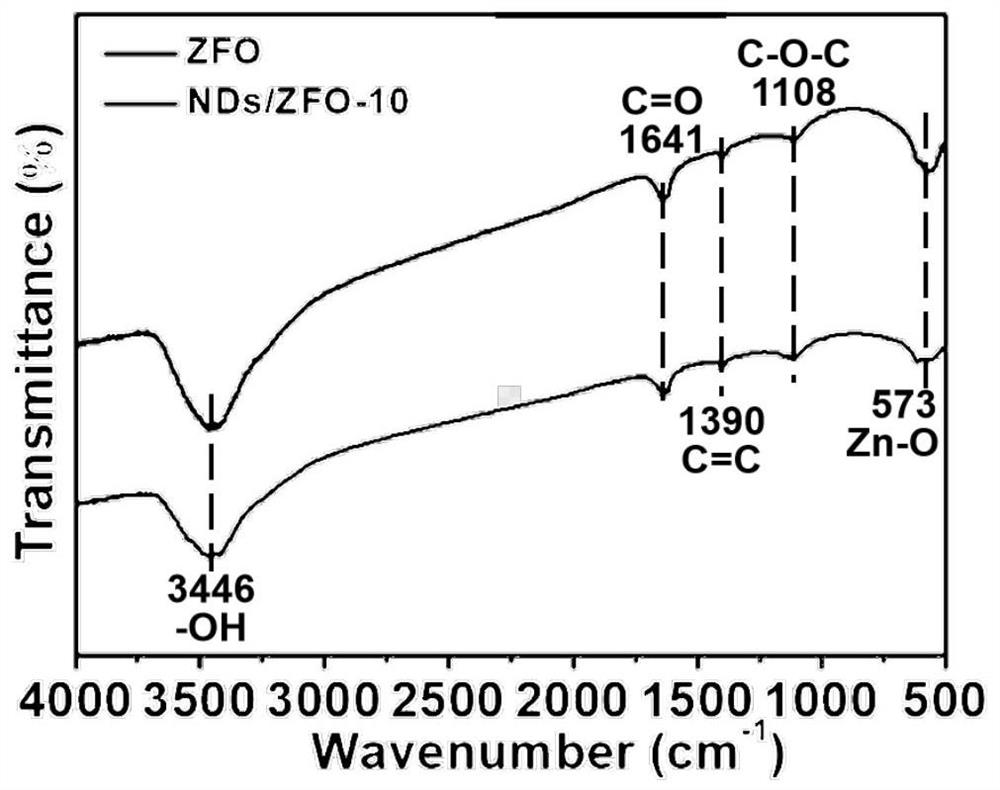

[0029] A photocatalyst consisting of nanodiamond NDs and yolk-shell structured ZnFe 2 o 4 , the incorporation mass of the NDs is ZnFe 2 o 4 1% of mass. Its preparation method is as follows:

[0030] At room temperature, 0.25 mmol of Zn(NO 3 ) 2 ·6H 2 O, 0.5mmol of Fe(NO 3 ) 3 9H 2 O and the theoretical formation of ZnFe 2 o 4 Add 1% of the mass of NDs into a beaker containing 50mL isopropanol and 10mL glycerin and mix well, then pour it into the reaction kettle, and react at 180°C for 6h. Wash 2 times and dry. The dried product was poured into a crucible, put into a muffle furnace, heated to 350°C at a heating rate of 10°C / min, and kept for 2 hours. After the muffle furnace was cooled to room temperature, the obtained sample was put into an agate mortar, ground to a uniform powder, collected for later use, and recorded as NDs / ZFO-1.

Embodiment 2

[0032] A photocatalyst consisting of nanodiamond NDs and yolk-shell structured ZnFe 2 o 4 , the incorporation mass of the NDs is ZnFe 2 o 4 3% of mass. Its preparation method is as follows:

[0033] At room temperature, 0.24 mmol of Zn(NO 3 ) 2 ·6H 2 O, 0.49mmol of Fe(NO 3 ) 3 9H 2 O and the theoretical formation of ZnFe 2 o 4Add 3% NDs by mass into a beaker containing 49.5mL isopropanol and 9.5mL glycerin and mix evenly, then pour it into the reaction kettle, and react at 170°C for 5h. After the reaction is completed and cooled, the mixture is centrifuged. Wash 3 times with alcohol and dry. The dried product was poured into a crucible, put into a muffle furnace, heated to 340°C at a heating rate of 9.5°C / min, and kept for 1.5h. After the muffle furnace was cooled to room temperature, the obtained sample was put into an agate mortar, ground to a uniform powder, collected for later use, and recorded as NDs / ZFO-3.

Embodiment 3

[0035] A photocatalyst consisting of nanodiamond NDs and yolk-shell structured ZnFe 2 o 4 , the incorporation mass of the NDs is ZnFe 2 o 4 5% of the mass. Its preparation method is as follows:

[0036] At room temperature, 0.27 mmol of Zn(NO 3 ) 2 ·6H 2 O, 0.51mmol of Fe(NO 3 ) 3 9H 2 O and the theoretical formation of ZnFe 2 o 4 Add 5% NDs by mass into a beaker containing 50.5mL isopropanol and 10.5mL glycerin and mix evenly, then pour it into the reaction kettle, and react at 190°C for 7h. After the reaction is completed and cooled, the mixture is centrifuged. Wash 4 times with alcohol and dry. The dried product was poured into a crucible, put into a muffle furnace, heated to 360°C at a heating rate of 9.7°C / min, and kept for 1.8h. After the muffle furnace was cooled to room temperature, the obtained sample was put into an agate mortar, ground to a uniform powder, collected for later use, and recorded as NDs / ZFO-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com