Biodegradable polyester and preparation method thereof

A technology for biodegrading polyester and carbonate, applied in the field of organic materials, to achieve good tensile properties, excellent tensile mechanical properties, and excellent degradation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

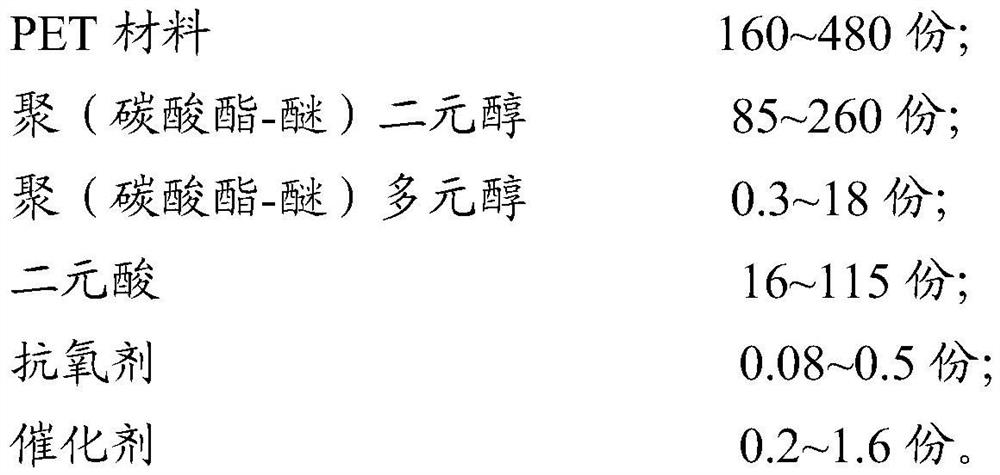

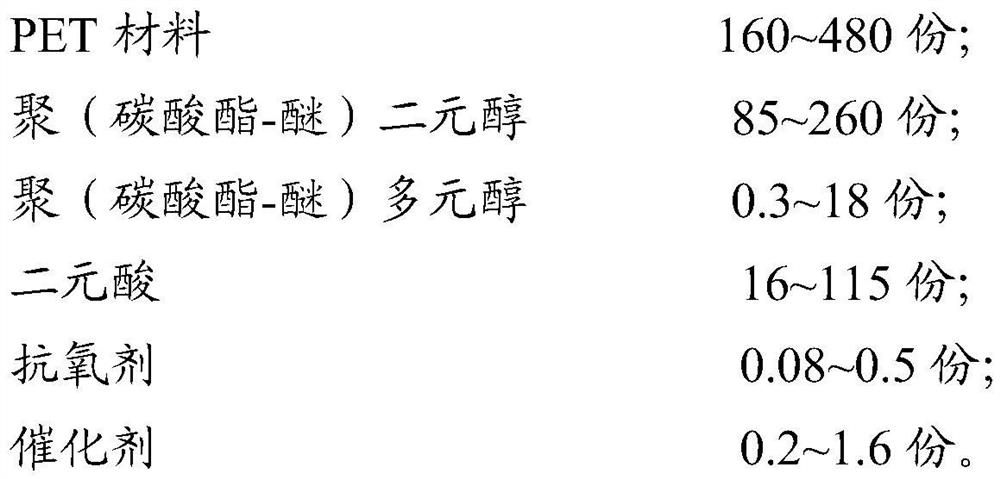

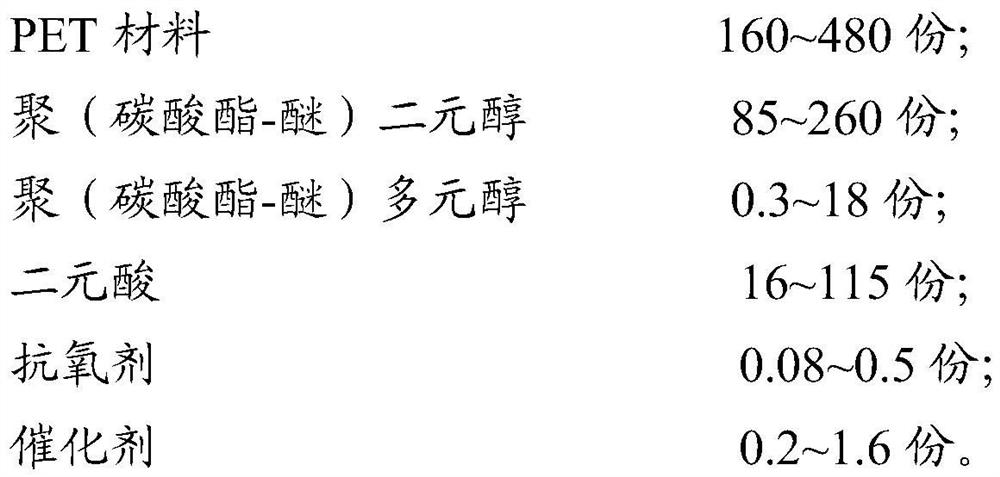

[0045] The present invention also provides a method of preparing a biodegradable polyester described in the above-described technical solution, comprising the steps of:

[0046] a) mix the PET material, poly (carbonate-ether) diol, catalyst, and antioxidant to obtain the first intermediate;

[0047] b) A mixture of the first intermediate and poly (carbonate-ether) polyol to obtain a second intermediate;

[0048] c) The second intermediate and dibasic acid mixed to obtain a biodegradable polyester.

[0049] Among them, the PET material, a poly (carbonate-ether) diol, poly (carbonate-ether) polyol, dibasic acid, catalyst, and antioxidant type and amount of oxygen-based, etc. are described in the above technical solution. Consistent, there is no longer described here.

[0050] With regard to step a): The PET material, the poly (carbonate-ether) diol, a catalyst, and an antioxidant were mixed to give the first intermediate.

[0051] In the present invention, the reaction is preferably...

Embodiment 1

[0070] Sl, under nitrogen, to the reactor were successively put into 160g of waste PET, 85g poly (carbonate - ether) diol (Mn = 3300g / mol, Cu% = 30.6%), 0.22g of tetrabutyl titanate, 0.08 after g of triethyl phosphite was heated to 140 deg.] C, stirring was started, the reaction for 2.5 hours to give a first intermediate.

[0071] S2, the system 200 is to continue to heat up deg.] C, the first intermediate was added to 0.35g of poly (carbonate - ether) tetraol (Mn = 2000g / mol, Cu% = 36.9%), 1.5 hours, obtain a second intermediates.

[0072] S3, the system was heated to 230 deg.] C continues, 16g of 1,3-propanedioic acid were added, reaction was continued for 2 hours, the system was evacuated to a reduced pressure of 1000Pa, the reaction for 1.5 hours under reduced pressure to continue the evacuation, the negative pressure control in 50Pa, 5 hours, an acid value of ≤3mgKOH / g, the reaction was stopped. The reaction product was extruded continuously from the bottom of the polym...

Embodiment 2

[0074] Sl, under nitrogen, to the reactor were successively put into 480g of waste PET, 260g poly (carbonate - ether) diol (Mn = 6000g / mol, Cu% = 34.3%), 1.58g tetraisopropyl titanate, after 0.42g pentaerythritol bisphosphite, temperature was raised to 180 ℃, began stirring, for 0.5 hours to give a first intermediate.

[0075] S2, the temperature was raised to 220 deg.] C, the first intermediate was added to 17.8g poly (carbonate - ether) hexahydric alcohols (Mn = 7900g / mol, Cu% = 50.8%), for 0.5 hours to obtain a second intermediate body.

[0076] S3, temperature continues to rise to 270 deg.] C, was added 115g of 1,4-succinic acid, the reaction was continued for 1 hour and the system was evacuated to a reduced pressure of 1000Pa, for 0.5 hr, and further evacuated under reduced pressure, the negative pressure control in 50Pa, reacted for 2 hours, the acid value ≤3mgKOH / g, the reaction was stopped, the reaction product from the bottom of the polymerization vessel continuousl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com