Hot air internal circulation type drying furnace for anti-static winding film with good tensile property

A technology of hot air internal circulation and stretching performance, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of high energy consumption, large energy consumption, and high cost of drying equipment, and achieve reduction Heat loss, energy saving, good tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

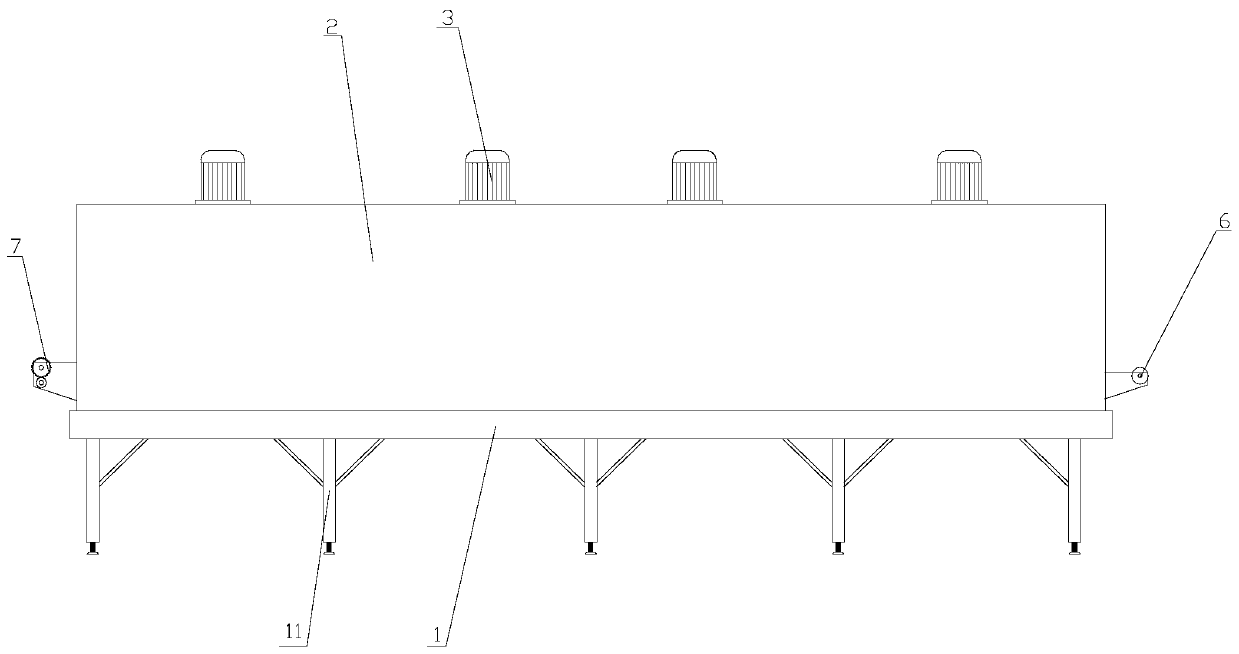

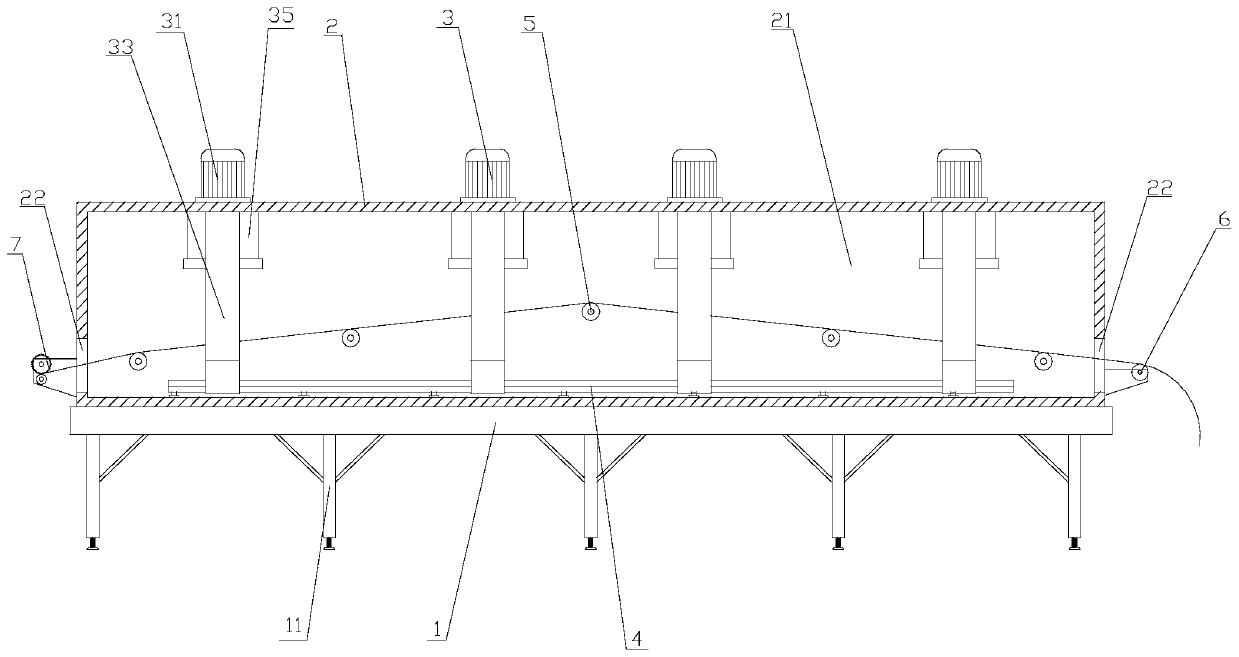

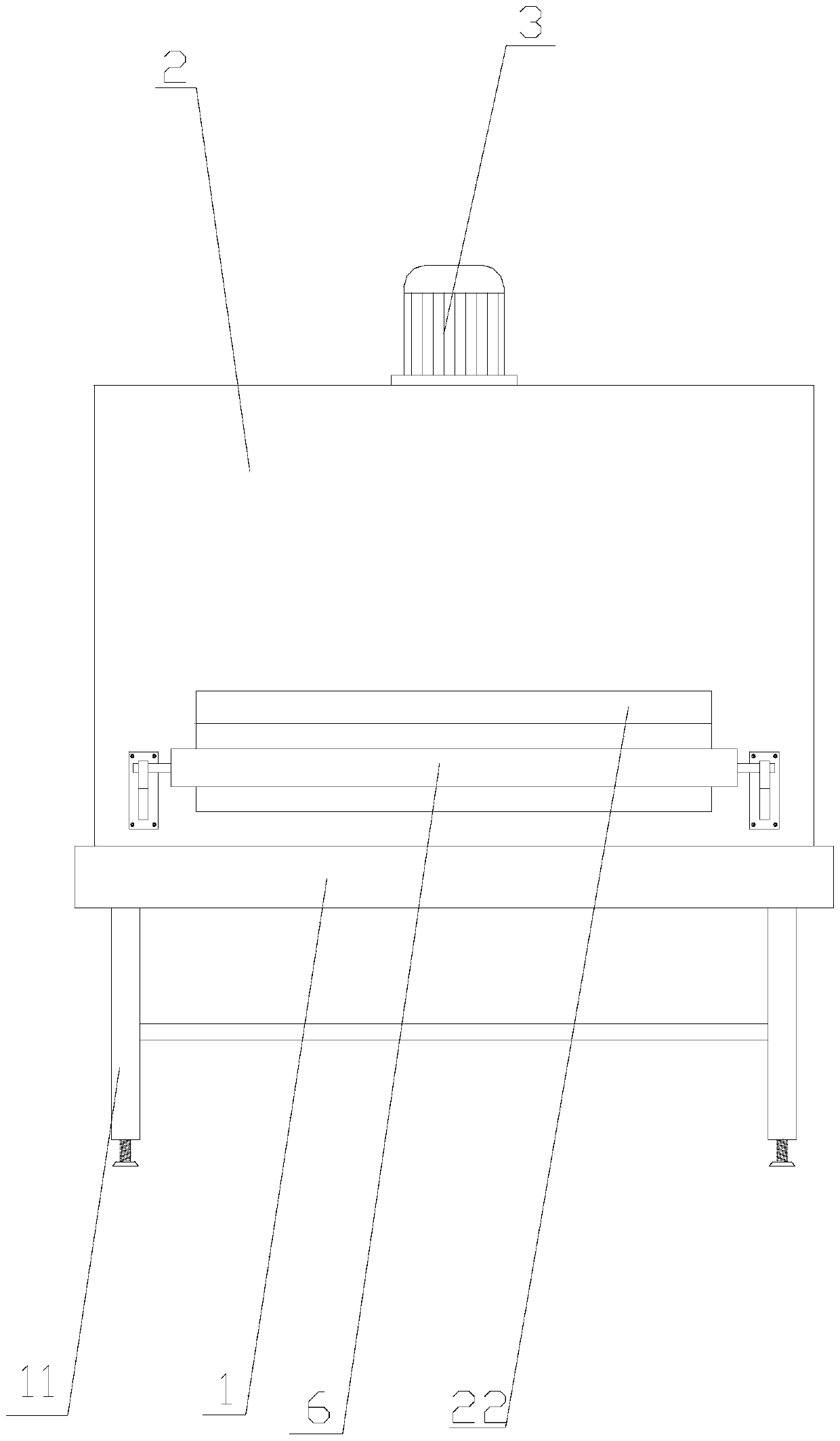

[0016] refer to figure 1 , figure 2 , image 3 and Figure 4 , a hot air internal circulation drying oven for an anti-static stretch film with good tensile properties according to the present invention, comprising a frame 1, a drying furnace body 2, several hot air internal circulation devices 3, a heater 4, and several conveying rollers 5 , into the film roller 6, out of the film roller 7, the upper end of the frame 1 is horizontally provided with a drying furnace body 2, the described drying furnace body 2 is provided with a drying cavity 21, and the described drying furnace body 2 The left and right sides of the furnace body 2 are respectively provided with a film inlet 22 and a film outlet 23. The film inlet 22 and the film outlet 23 are all connected to the drying chamber 21, and the sides of the drying furnace body 2 are close to The film inlet 22 is provided with a film inlet roller 6 that can cooperate with it, and the side of the drying furnace body 2 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com