Gas shielded welding method for low-carbon Q420q bridge steel

A gas-shielded welding and gas-shielded technology, applied in welding equipment, welding medium, welding equipment, etc., can solve problems affecting the popularization and application of new bridge steel, difficult construction environment, long project cycle, etc., achieve economical welding process and promote promotion , Excellent tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A gas shielded welding method for low-carbon Q420q bridge steel, the specific steps are as follows:

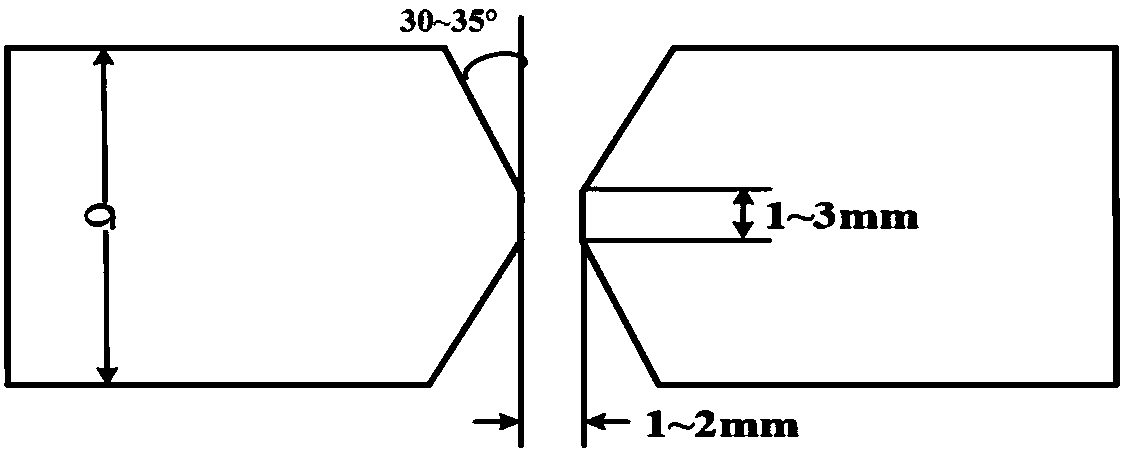

[0038] Step 1, beveling:

[0039] Double-sided V-shaped symmetrical grooves are made on the Q420q bridge steel plate with a base plate combination of 14+14mm and a single-side base plate size of 400×200×14mm. The groove angle is 60°, and the blunt edge is 1mm. Gap 1mm;

[0040] Step 2, preprocessing:

[0041] Use 600-mesh sandpaper to grind the V-shaped symmetrical groove and the steel plate within 5cm on both sides, and then clean it with acetone to remove rust and impurities to ensure the quality of the welded joint;

[0042] Step 3, soldering:

[0043] (1) at 20% CO 2 Under the protection of +80% Ar mixed gas, the root welding is carried out. The welding current of the root welding is 200A, the welding voltage is 22V, the welding speed is 400mm / min, and the input energy is 6.6kJ / cm;

[0044] (2) After bottom welding, in 20% CO 2 Filling welding is carried out u...

Embodiment 2

[0047] A gas shielded welding method for low-carbon Q420q bridge steel, the specific steps are as follows:

[0048] Step 1, beveling:

[0049] Double-sided V-shaped symmetrical grooves are made on the Q420q bridge steel plate with a substrate combination of 20+20mm and a single-sided substrate size of 400×200×20mm. The groove angle is 60° and the blunt edge is 2mm. Gap 1.30mm;

[0050] Step 2, preprocessing:

[0051] Use 600-mesh sandpaper to grind the V-shaped symmetrical groove and the steel plate within 5cm on both sides, and then clean it with acetone to remove rust and impurities to ensure the quality of the welded joint;

[0052] Step 3, soldering:

[0053] (1) at 20% CO 2 Under the protection of +80% Ar mixed gas, the root welding is carried out. The welding current of the root welding is 230A, the welding voltage is 24V, the welding speed is 360mm / min, and the input energy is 9.2kJ / cm;

[0054] (2) After bottom welding, in 20% CO 2 The filling welding is carried ou...

Embodiment 3

[0058] A gas shielded welding method for low-carbon Q420q bridge steel, the specific steps are as follows:

[0059] Step 1, beveling:

[0060] Double-sided V-shaped symmetrical grooves are made on the Q420q bridge steel plate with a substrate combination of 40+40mm and a single-sided substrate size of 400×200×40mm. The groove angle is 55° and the blunt edge is 3mm. Gap 2mm;

[0061] Step 2, preprocessing:

[0062] Use 600-mesh sandpaper to grind the V-shaped symmetrical groove and the steel plate within 5cm on both sides, and then clean it with acetone to remove rust and impurities to ensure the quality of the welded joint;

[0063] Step 3, soldering:

[0064] (1) at 20% CO 2 Under the protection of +80% Ar mixed gas, the root welding is carried out. The welding current of the root welding is 280A, the welding voltage is 26V, the welding speed is 330mm / min, and the input energy is 13.23kJ / cm;

[0065] (2) After bottom welding, in 20% CO 2 The filling welding is carried o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com