Organosilicon pressure-sensitive adhesive for fingerprint-resistant glass as well as preparation method and application of organosilicon pressure-sensitive adhesive

A silicone pressure-sensitive adhesive and anti-fingerprint technology, used in pressure-sensitive films/sheets, adhesives, adhesive additives, etc. It can improve the stability of temperature resistance and peel force, improve the exhaust performance, and improve the cohesive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

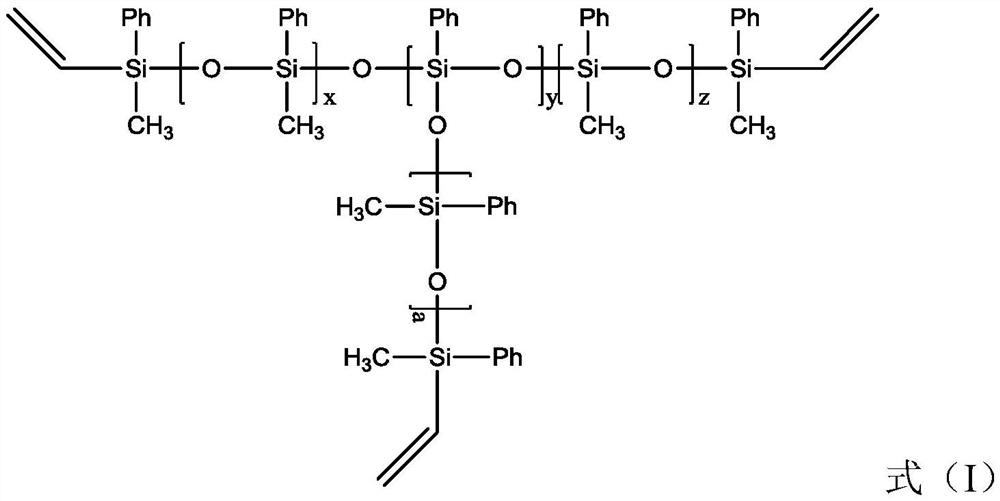

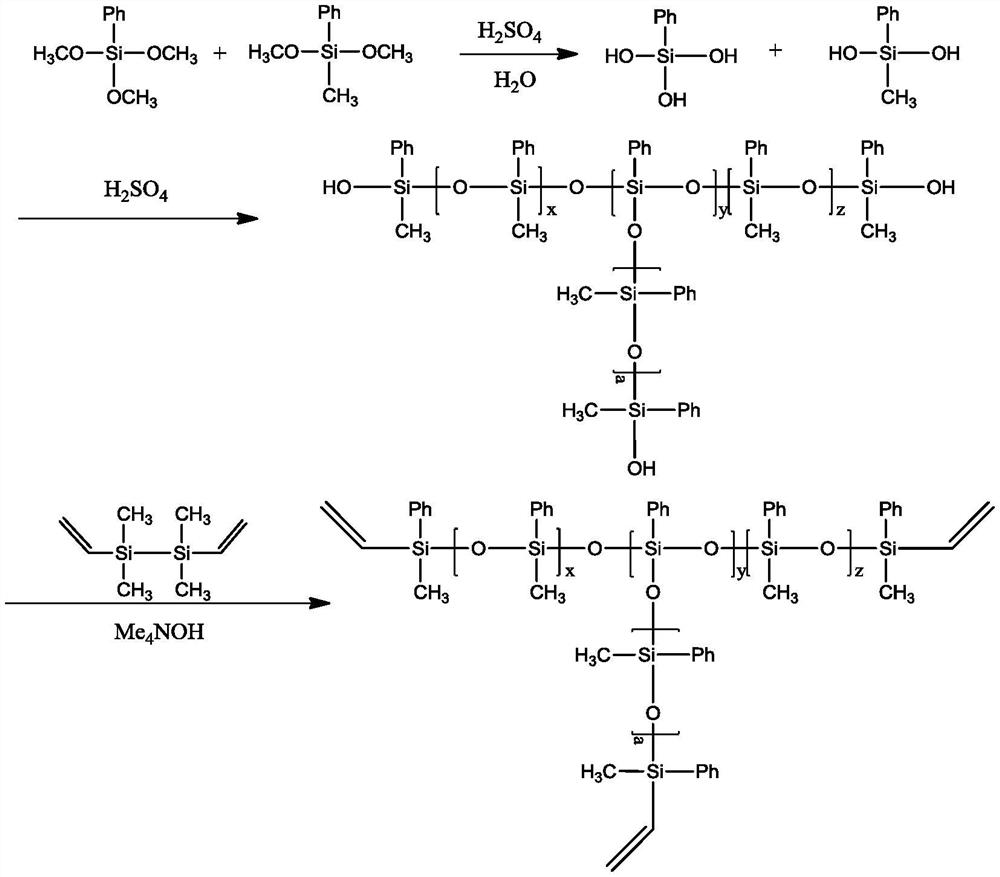

[0030] The preparation method of branched vinyl silicone oil comprises the hydrolytic condensation of phenyltrimethoxysilane and methylphenyldimethoxysilane, under the catalysis of acid, phenyltrimethoxysilane and methylphenyldimethoxysilane The hydrolysis reaction of base silane, and further dehydration condensation to obtain hydroxyl-terminated T-type polysiloxane chain segment, when the number of chain segments reaches a certain amount, vinyl double-capped head is added for end-capping reaction, and finally separated and purified to obtain T-shaped polysiloxane segment Branched vinyl silicone oil.

[0031] In the preparation process of the above-mentioned branched vinyl silicone oil, the catalyst of the acid is selected from any one of concentrated sulfuric acid, acetic acid, propionic acid, benzoic acid, phenylacetic acid, trifluorobenzenesulfonic acid, acid diatomaceous earth, etc., preferably For concentrated sulfuric acid.

[0032] The preparation steps of branched vin...

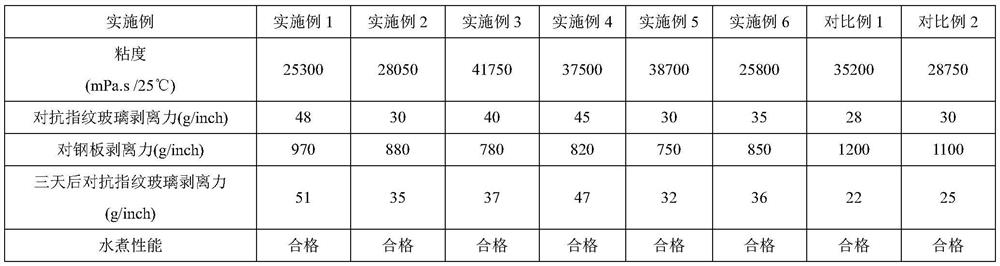

Embodiment 1

[0078] 1) Add 20g of branched vinyl silicone oil, 10g of vinyl MQ silicone resin, 20g of hydroxyl raw rubber, 60g of hydroxyl MQ silicone resin, 80g of xylene, and 0.8g of ethynyl cyclohexanol into the reactor, stir and dissolve; wherein, hydroxyl raw The molecular weight of the glue is 600,000; the viscosity of branched vinyl silicone oil is 500mPa·s, and the mass fraction of vinyl is 1.5%; the ratio of hydroxyl MQ silicone resin to vinyl MQ is 6:1;

[0079] 2) Stir with nitrogen gas, after stirring evenly, dilute 0.8g of acetic acid with 20g of xylene and add slowly, then react at 150°C for 4h under reflux dehydration;

[0080] 3) Cool to room temperature, add 1.5 g of silicon hydrogen cross-linking agent and stir evenly to obtain pressure-sensitive adhesive base 1;

[0081] 4) Add 0.5g of anchoring agent and 100g of toluene to 100g of base glue 1, stir evenly, add 1.5g of platinum catalyst with a platinum content of 4000ppm, stir evenly, spread on an 80μm thick SRF substrat...

Embodiment 2

[0083] 1) Add 15g of branched vinyl silicone oil, 10g of vinyl MQ silicone resin, 25g of hydroxyl raw rubber, 60g of hydroxyl MQ silicone resin, 80g of xylene, and 0.8g of ethynyl cyclohexanol into the reactor, stir and dissolve; wherein, hydroxyl raw The molecular weight of the glue is 620,000; the viscosity of branched vinyl silicone oil is 1000mPa·s, the mass fraction of vinyl is 1.5%, and the ratio of hydroxyl MQ silicone resin to vinyl MQ is 6:1;

[0084] 2) Stir with nitrogen gas, after stirring evenly, dilute 0.8g of acetic acid with 20g of xylene and add slowly, then react at 150°C for 4h under reflux dehydration;

[0085] 3) Cool to room temperature, add 1.5 g of silicon hydrogen cross-linking agent and stir evenly to obtain pressure-sensitive adhesive base 2;

[0086] 4) Add 0.5g of anchoring agent and 100g of ethyl acetate to 100g of base glue 2, stir evenly, add 1.5g of platinum catalyst with a platinum content of 4000ppm, stir evenly, spread on the 80μm thick SRF ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com