Degradable polyester-polycarbonate copolymer with high gas barrier property as well as preparation method and application thereof

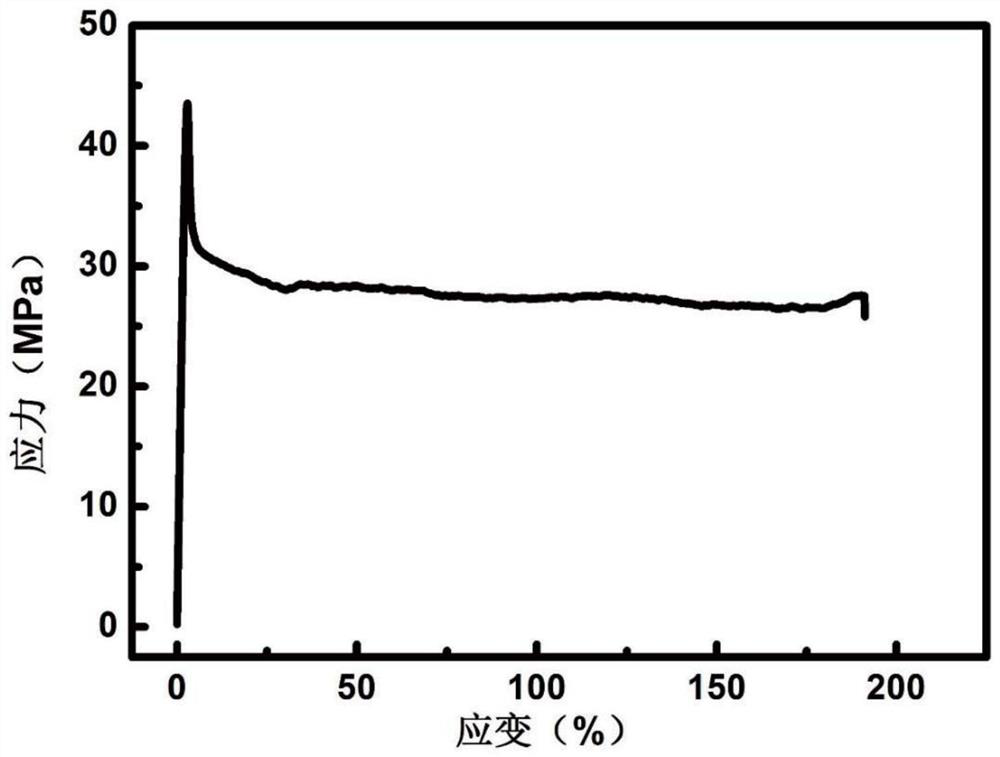

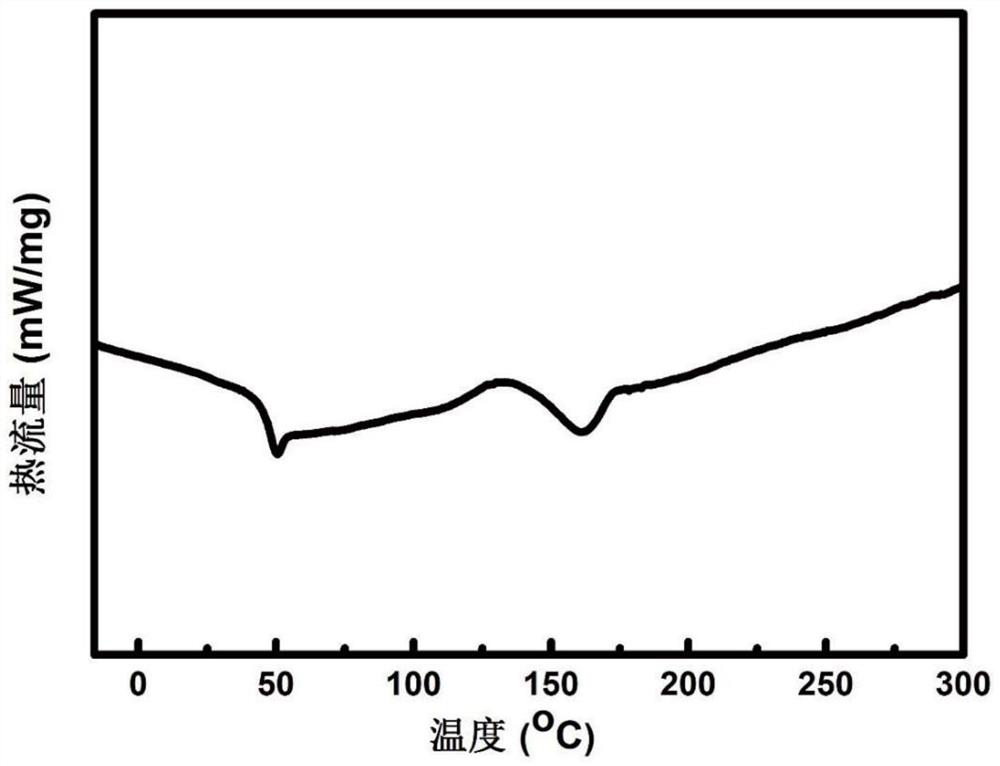

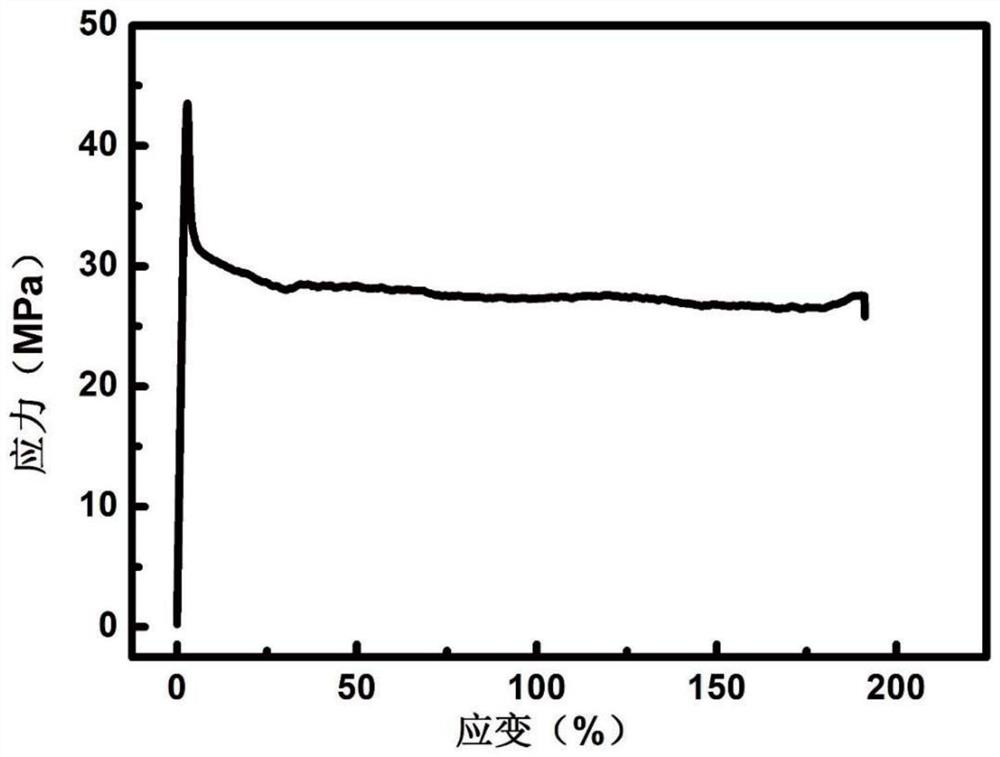

A gas barrier and polycarbonate technology, applied in the field of polymer materials, can solve the problems of degradable polyester mechanical properties, poor heat resistance gas barrier performance, etc., to achieve improved gas barrier performance, excellent comprehensive performance, excellent gas barrier performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A method for preparing a degradable high gas barrier polyester-polycarbonate copolymer provided by an aspect of the embodiments of the present invention includes:

[0046] (1) Under a protective atmosphere, the first mixed reaction system comprising carbonic acid diester, the first dihydric alcohol, and the first transesterification catalyst is subjected to transesterification at 90 to 220° C., and the first intermediate product is formed after completion ;

[0047] (2) Under protective atmosphere, make the catalyst containing bio-based aromatic dibasic acid and / or esterification thereof, adipic acid and / or esterification thereof, the second glycol, the second esterification or transesterification The second mixed reaction system is subjected to esterification or transesterification reaction at 140-240°C, and the second intermediate product is obtained after completion;

[0048](3) The third mixed reaction system comprising the first intermediate product, the second in...

Embodiment 1

[0116] 56.8g (0.63mol) of dimethyl carbonate, 41.2g (0.21mol) of tricyclodecane dimethanol and 0.1% tetrabutyl titanate of the theoretical mass of the polycarbonate tricyclodecane dimethanol oligomer are put into the reaction In the container, under the condition of nitrogen protection, the temperature was gradually raised to 90°C, and the reaction was carried out for 36.0h. After the end, the temperature was lowered to room temperature at a cooling rate of 10°C / min, and then kept in a nitrogen atmosphere for 1h to obtain polycarbonate tricyclodecane Dimethyl ester oligomers.

[0117] 38.7g (0.225mol) of 2,5-thiophene dicarboxylic acid, 40.2g (0.275mol) of adipic acid, 117.8g (0.6mol) of tricyclodecane dimethanol and poly-2,5-thiophene dicarboxylate Put 0.1% tetrabutyl titanate of the theoretical mass of tricyclodecane dimethanol ester oligomer into the reactor, and gradually raise the temperature to 240°C under the condition of nitrogen protection, and react for 4.0h. The te...

Embodiment 2

[0126]56.8g (0.63mol) of dimethyl carbonate, 82.4g (0.42mol) of tricyclodecane dimethanol and 0.2% tetrabutyl titanate of the theoretical mass of the polycarbonate tricyclodecane dimethanol oligomer are put into the reaction In the container, under the condition of nitrogen protection, the temperature was gradually raised to 90°C, and the reaction was carried out for 30.0h. After the end, the temperature was lowered to room temperature at a cooling rate of 20°C / min, and then kept in a nitrogen atmosphere for 2h to obtain polycarbonate tricyclodecane Dimethyl ester oligomers.

[0127] 38.7g (0.225mol) of 2,5-thiophene dicarboxylic acid, 40.2g (0.275mol) of adipic acid, 157.07g (0.8mol) of tricyclodecane dimethanol and poly-2,5-thiophene dicarboxylate Put 0.01% tetrabutyl titanate of the theoretical mass of tricyclodecane dimethanol ester oligomer into the reactor, and gradually raise the temperature to 220°C under the condition of nitrogen protection, and react for 6.0h. The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com