Sliding water outlet with a micro -expansion of carbon fire -resistant mud and production methods

A sliding nozzle and refractory mud technology, which is applied in the direction of manufacturing tools, casting melt containers, casting equipment, etc., can solve the problems of increased labor intensity of sliding nozzle products, large shrinkage of fire mud, and difficulty in cleaning, etc., so as to prevent the penetration of molten steel and reduce Effect of shrinkage rate and good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

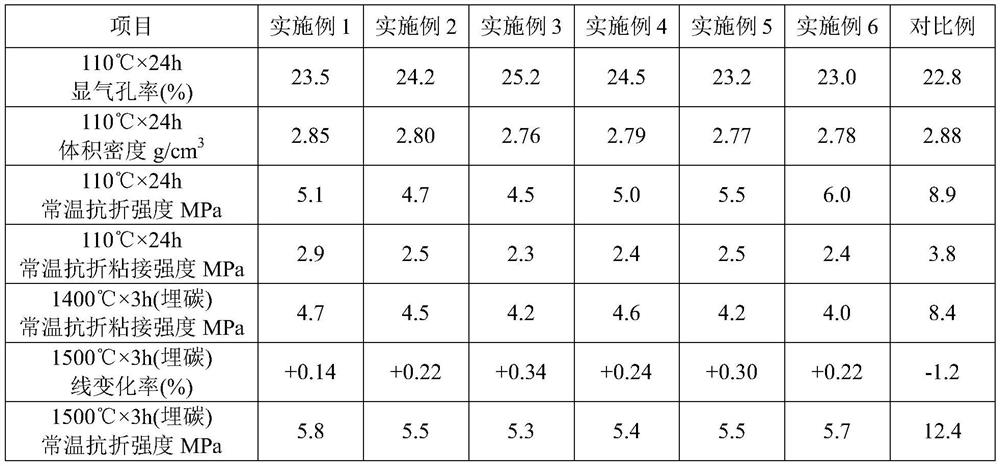

Examples

Embodiment 1

[0027] Micro-expanded carbon-containing refractory mud for sliding nozzles, by weight percentage, the raw material composition is: 68% fused mullite, 5% kyanite, 8% fused white corundum powder, 5% calcined alumina Micro powder, 5% Guangxi white mud, 5% flake graphite, 2% solid aluminum dihydrogen phosphate, 2% boron nitride, plus 2% gum arabic powder and 1% carboxymethyl cellulose.

[0028] Among them, the fused mullite includes: 0.2mm<grain size 1≤0.5mm, 0.074mm<grain size 2≤0.2mm, grain size 3≤0.074mm, and the weight ratio of different grain sizes is: grain size 1: grain size 2: grain size 3=8 : 10:50.

[0029] The particle size of fused white corundum powder is less than or equal to 0.045mm; the particle size of kyanite is less than or equal to 0.2mm; the particle size of Guangxi white mud is less than or equal to 0.2μm; the particle size of flake graphite is less than or equal to 0.074mm, and the carbon content is greater than or equal to 98%; D50 is 1 μm to 2 μm; the pa...

Embodiment 2

[0038] Micro-expanded carbon-containing refractory mud for sliding nozzles, by weight, the raw material composition is: 65% fused mullite, 8% kyanite, 8% fused white corundum powder, 5% calcined alumina Micro powder, 5% Guangxi white mud, 5% flake graphite, 2% solid aluminum dihydrogen phosphate, 2% boron nitride, plus 2% gum arabic powder and 1% carboxymethyl fiber in total of the above raw materials white.

[0039] Among them, the fused mullite includes: 0.2mm

[0040]The particle size of fused white corundum powder is less than or equal to 0.045mm; the particle size of kyanite is less than or equal to 0.2mm; the particle size of Guangxi white mud is less than or equal to 0.2μm; the particle size of flake graphite is less than or equal to 0.074mm, and the carbon content is greater than or equal to 98%; D50...

Embodiment 3

[0043] Micro-expanded carbon-containing refractory mud for sliding nozzles, by weight percentage, the raw material composition is: 63% fused mullite, 10% kyanite, 8% fused white corundum powder, 5% calcined alumina Micro powder, 5% Guangxi white mud, 5% flake graphite, 2% solid aluminum dihydrogen phosphate, 2% boron nitride, plus 2% gum arabic powder and 1% carboxymethyl fiber in total of the above raw materials white.

[0044] Among them, the fused mullite includes: 0.2mm

[0045] The particle size of fused white corundum powder is less than or equal to 0.045mm; the particle size of kyanite is less than or equal to 0.2mm; the particle size of Guangxi white mud is less than or equal to 0.2μm; the particle size of flake graphite is less than or equal to 0.074mm, and the carbon content is greater than or equal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com