Preparation method of 1, 1, 1-tris (4-hydroxyphenyl) ethane

A technology of hydroxyphenyl and hydroxyacetophenone, applied in the first field, can solve the problems of high price of 3-mercaptopropanesulfonic acid sodium salt, inability to effectively recycle, inability to completely remove, etc., to save the cost of three wastes treatment and product yield The effect of high rate and less side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Dissolve titanium sulfate solution in distilled water, add polyethylene glycol solution with a mass fraction of 1% to 2%, add ZSM-5 molecular sieve and stir evenly, then gradually add ammonia water dropwise under strong stirring, form a precipitate and put it in an ice water bath Aging; washing and suction filtration, drying the filter cake at 100°C, grinding it into powder, immersing in 1mol / L sulfuric acid solution for 12 hours, filtering, drying the filter cake at 100°C for 3 hours, and then roasting at 500°C for 5 hours to obtain the solid superacid Scat05.

Embodiment 2

[0033] Weigh 54.4g 4-hydroxyacetophenone, 108.8g dichloroethane, 112.8g phenol, 5g solid acid catalyst SO 4 2- / TiO 2 Add it to a 1000ml three-neck flask, and feed it with a dry and stable nitrogen flow. After the reaction system was raised to an internal temperature of 60°C, it was kept warm for 14 hours and filtered to obtain an orange-yellow solid powder; after methanol was added to filter and recover the solid acid catalyst, after decolorization by activated carbon and sodium borohydride, 39.6 g of off-white powder was obtained by adding water to precipitate 1,1,1 ,-tris(4-hydroxyphenyl)ethane.

[0034] HPLC detected 96.8%, and the yield was 32.3%.

Embodiment 3

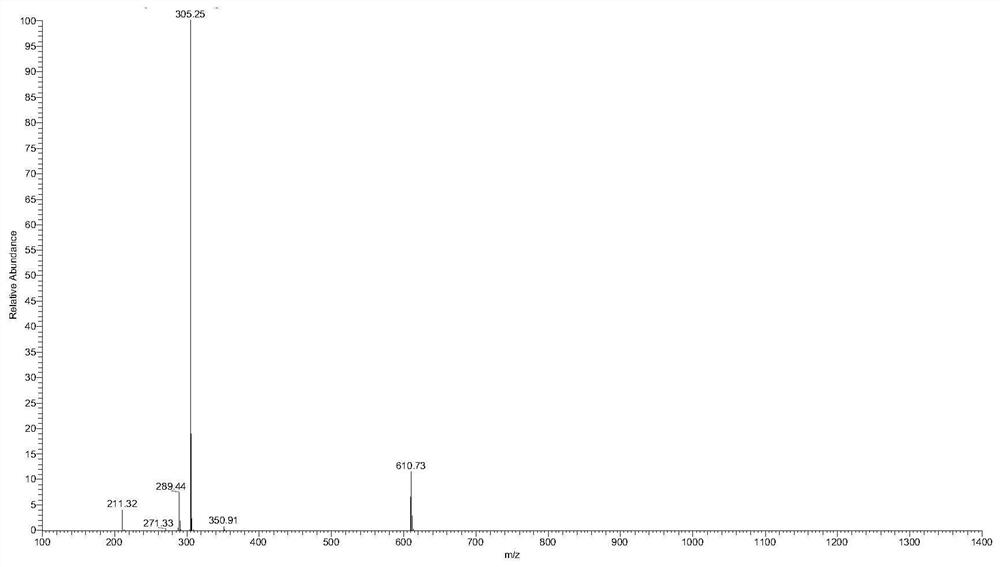

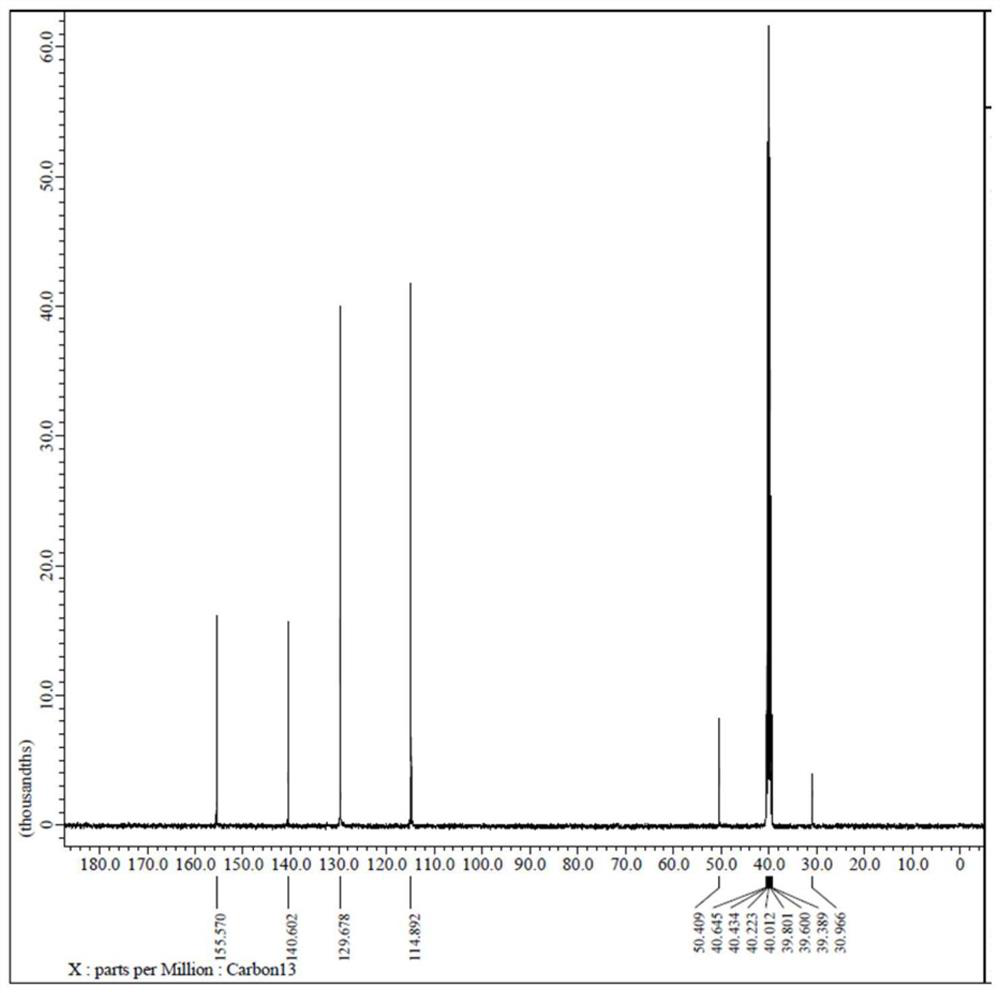

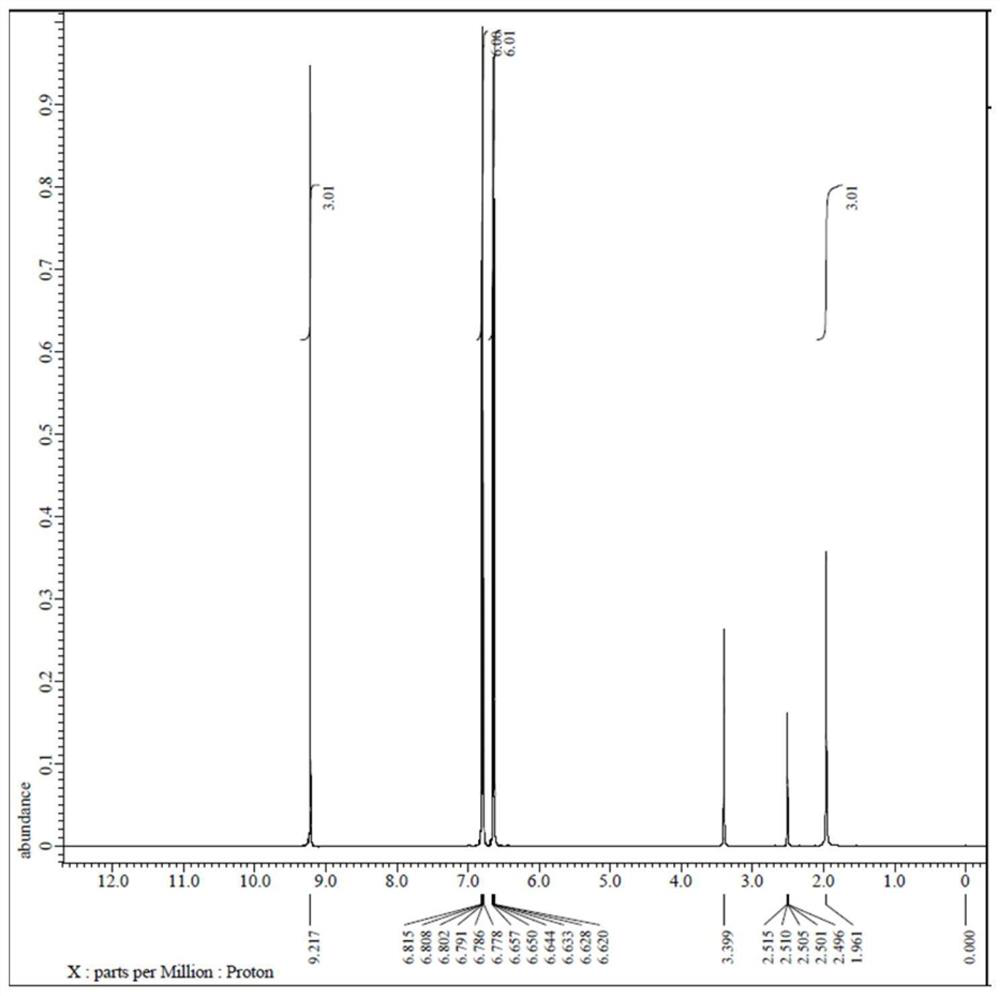

[0036] Weigh 54.4g of 4-hydroxyacetophenone, 163.2g of dichloroethane, 225.6g of phenol, and 5g of solid acid catalyst Scat05 into a 1000ml three-necked flask, and pass through a dry and stable nitrogen flow. After the reaction system was raised to an internal temperature of 50°C, it was kept warm for 7 hours, and then filtered to obtain an orange-yellow solid powder; after methanol was added to filter and recover the solid acid catalyst, after decolorization by activated carbon and sodium borohydride, 98.8 g of off-white powder was obtained by adding water to precipitate 1,1,1 ,-tris(4-hydroxyphenyl)ethane. The HPLC detection is 99.59%, and the yield is 80.62%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com