Preparation method of polyester plasticizer as well as product and application thereof

A polyester plasticizer and polyester technology, applied in the field of polyester plasticizer and rubber additives, can solve the problems of long time required and slow enzyme-catalyzed reaction speed, and achieve the effect of reducing reaction energy consumption and polycondensation reaction Good effect of lifting and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

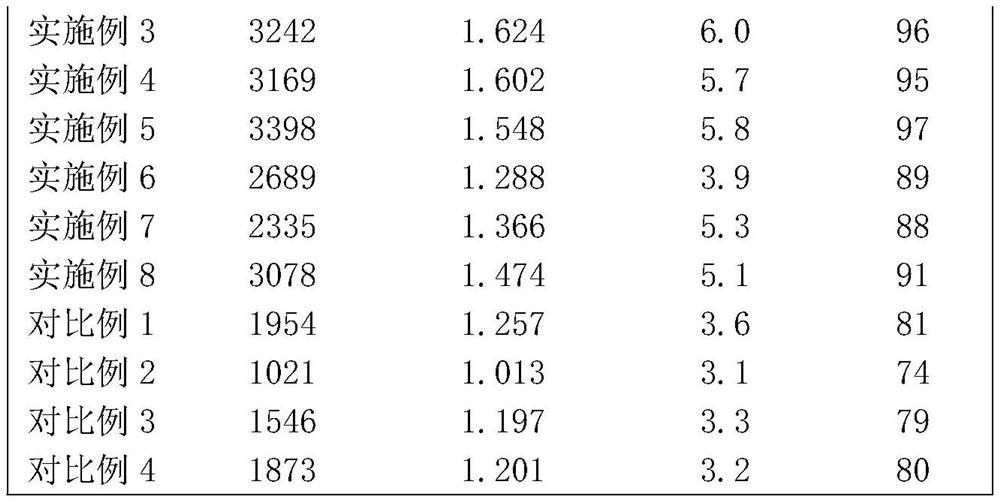

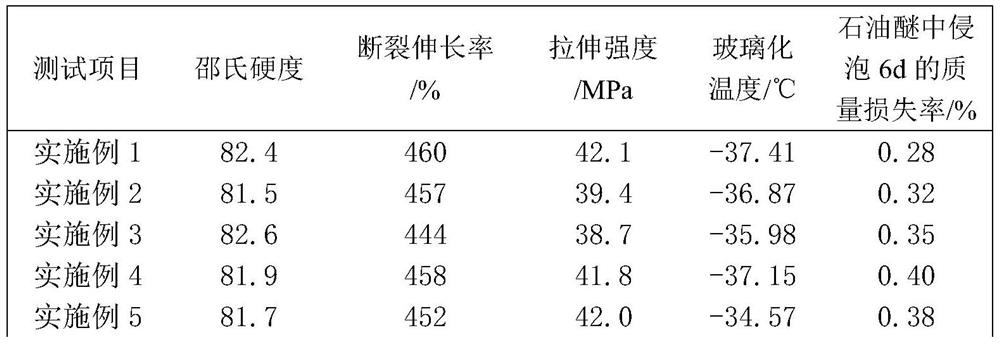

Examples

Embodiment 1

[0044] (1) Using succinic acid, butanediol, and 1,3-propanediol as raw materials, the molar ratio of alkyd to acid is 1.5:1, carry out esterification reaction at normal pressure, under the protection of nitrogen, heat up to 120°C, and continue to stir Reaction 3h makes prepolymer;

[0045] (2) Under the protection of nitrogen, reduce the temperature to 70°C, add Novozym435 (5wt%, calculated based on the total mass of the substrate), and open the vacuum device, control the pressure to 500Pa, carry out decompression to remove water, and react for 12h to obtain poly crude ester;

[0046] (3) Mix the crude polyester and polydimethylsiloxane at a molar ratio of 1:0.2, in dibutyltin dilaurate (the amount is 5‰ of the total molar mass of the crude polyester and polydimethylsiloxane) Carry out the grafting reaction under the action, the initial reaction temperature is 140°C, the time is 1h, the temperature is gradually raised to 180°C, the reaction is 3h, and the modified polyester c...

Embodiment 2

[0049] (1) Use adipic acid, butanediol, 1,3-propanediol, and the molar ratio of alkyd to 1.5:1 to carry out esterification reaction at normal pressure. Under the protection of nitrogen, heat up to 120°C and continue to stir for 3 hours. Prepare the prepolymer;

[0050] (2) Under the protection of nitrogen, reduce the temperature to 70°C, add Novozym435 (5wt%, calculated based on the total mass of the substrate), and open the vacuum device, control the pressure to 500Pa, carry out decompression to remove water, and react for 12h to obtain poly crude ester;

[0051] (3) Mix the crude polyester and polydimethylsiloxane at a molar ratio of 1:0.2, in dibutyltin dilaurate (the amount is 5‰ of the total molar mass of the crude polyester and polydimethylsiloxane) Carry out the grafting reaction under the action, the initial reaction temperature is 140°C, the time is 1h, the temperature is gradually raised to 180°C, the reaction is 3h, and the modified polyester crude product is obtai...

Embodiment 3

[0054] (1) Using succinic acid, sebacic acid, pentanediol, octanediol, and hexanediol as raw materials, the alkyd acid molar ratio is 1.5:1, carry out esterification reaction at normal pressure, and heat up under the protection of nitrogen To 120°C, continue stirring for 3 hours to prepare the prepolymer;

[0055] (2) Under the protection of nitrogen, reduce the temperature to 70°C, add Novozym435 (5wt%, calculated based on the total mass of the substrate), and open the vacuum device, control the pressure to 500Pa, carry out decompression to remove water, and react for 12h to obtain poly crude ester;

[0056] (3) Mix the crude polyester and polydimethylsiloxane at a molar ratio of 1:0.2, in dibutyltin dilaurate (the amount is 5‰ of the total molar mass of the crude polyester and polydimethylsiloxane) Carry out the grafting reaction under the action, the initial reaction temperature is 140°C, the time is 1h, the temperature is gradually raised to 180°C, the reaction is 3h, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com