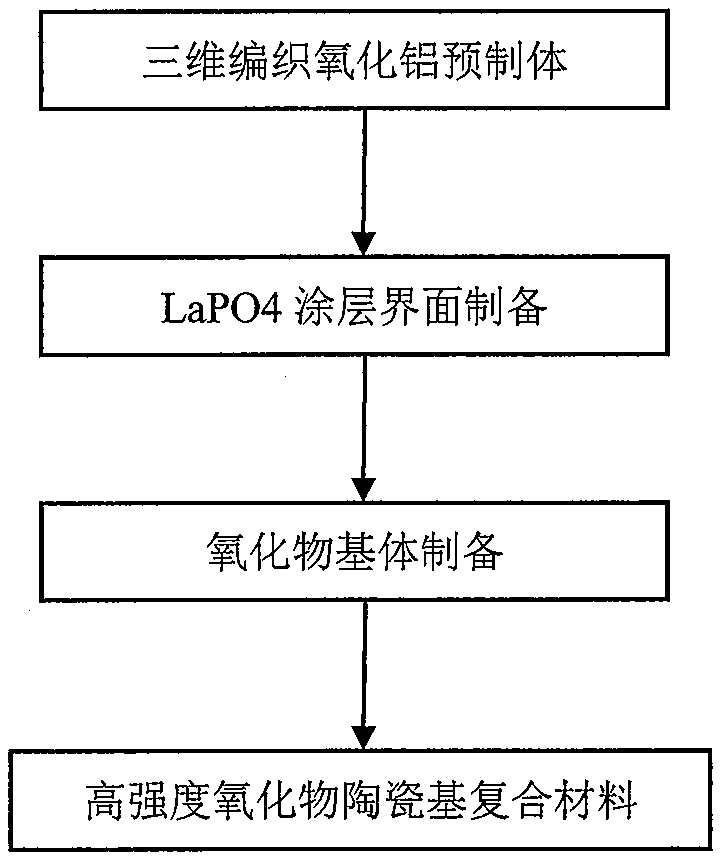

Novel high-strength oxide ceramic-based composite material and preparation method thereof

A technology of oxide ceramics and composite materials, which is applied in the field of preparation of new high-strength oxide ceramic matrix composite materials, to achieve the effect of uniform matrix, excellent mechanical properties and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Using a three-dimensional five-way weaving process, the alumina fiber is woven into a fiber prefabricated body, and the size of the prefabricated body is 60×60×5 mm 3 flat fiber preform;

[0022] (2) Place the fiber preform in step (1) in a tube furnace, and calcinate for 30 minutes in an air environment at 800°C;

[0023] (3) Treat the precursor solution of lanthanum phosphate in a cold water bath at 1° C. for 15 minutes, and mix the prepared lanthanum phosphate precursor solution at 1° C. according to the ratio of atomic ratio lanthanum: phosphorus = 1:1 Configured as a lanthanum phosphate mixed solution with a mass concentration of 80g / L; the precursor solution for preparing lanthanum phosphate is a combination of phosphoric acid aqueous solution and lanthanum citrate aqueous solution;

[0024] (4) At room temperature, immerse the fiber preform calcined in step (2) into the lanthanum phosphate mixed solution prepared in step (3) for 20 minutes, take out the fibe...

Embodiment 2

[0031] (1) Using the three-dimensional four-way weaving process, the alumina fiber is woven into a fiber prefabricated body, and the size of the prefabricated body is 120×120×10mm 3 flat fiber preform;

[0032] (2) Place the fiber preform in step (1) in a tube furnace, and calcinate for 60 minutes in an air environment at 600°C;

[0033] (3) Treat the precursor solution of lanthanum phosphate in a cold water bath at 3° C. for 15 minutes, and mix the prepared lanthanum phosphate precursor solution at 3° C. according to the ratio of atomic ratio lanthanum: phosphorus = 1:1 Configured as a lanthanum phosphate mixed solution with a mass concentration of 100g / L; the precursor solution for preparing lanthanum phosphate is a combination of phytic acid aqueous solution and lanthanum nitrate aqueous solution;

[0034] (4) At room temperature, immerse the fiber preform calcined in step (2) into the lanthanum phosphate mixed solution prepared in step (3) for 30 minutes, take out the fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com