High-bulk-density acrylic acid thickening agent as well as preparation method and application thereof

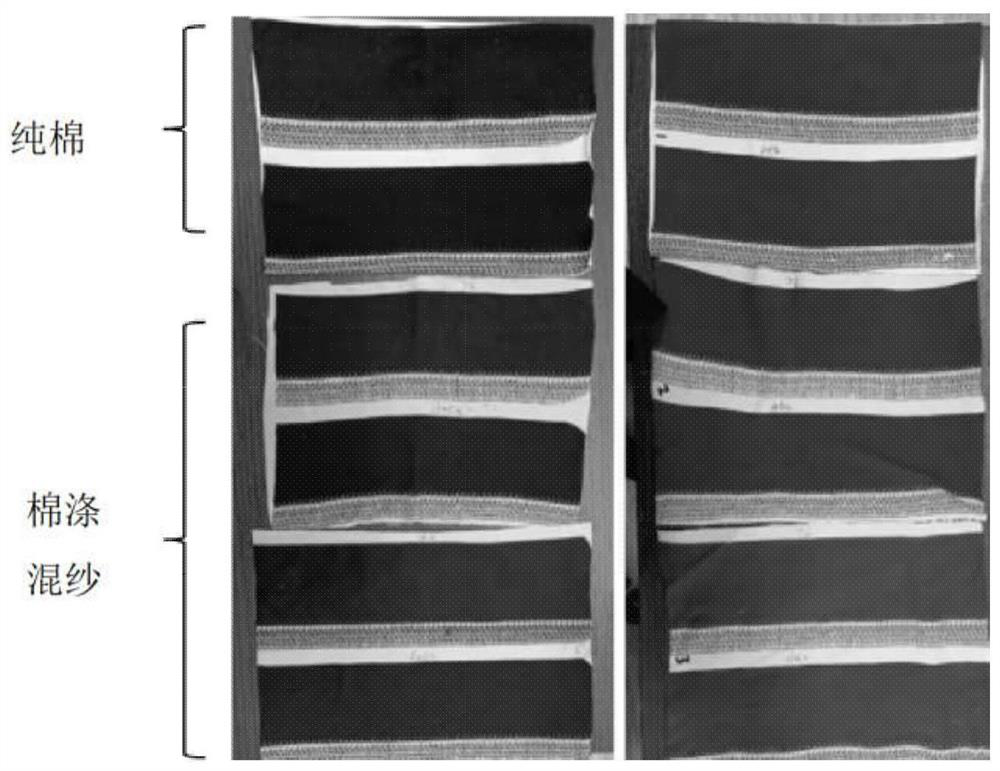

An acrylic thickener and bulk density technology, applied in the field of polymers, can solve problems such as limited application prospects and unfavorable application characteristics, and achieve the effects of simple operation, fast dispersion, and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

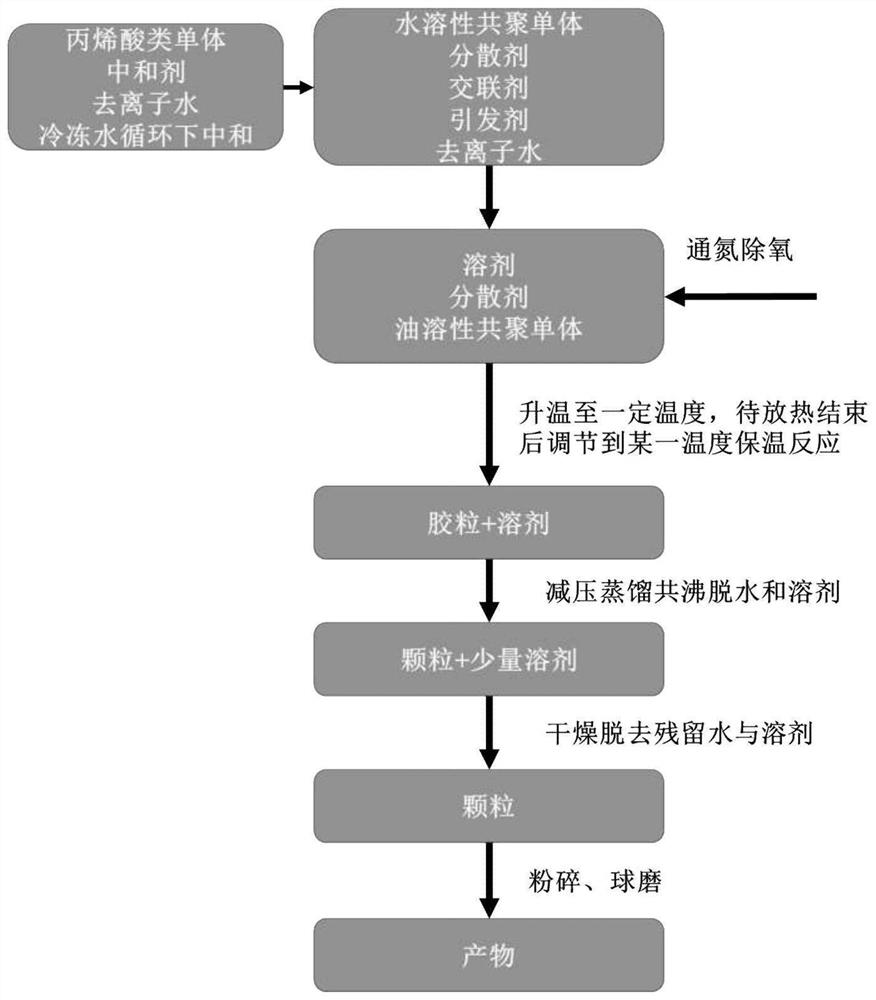

Method used

Image

Examples

Embodiment 1

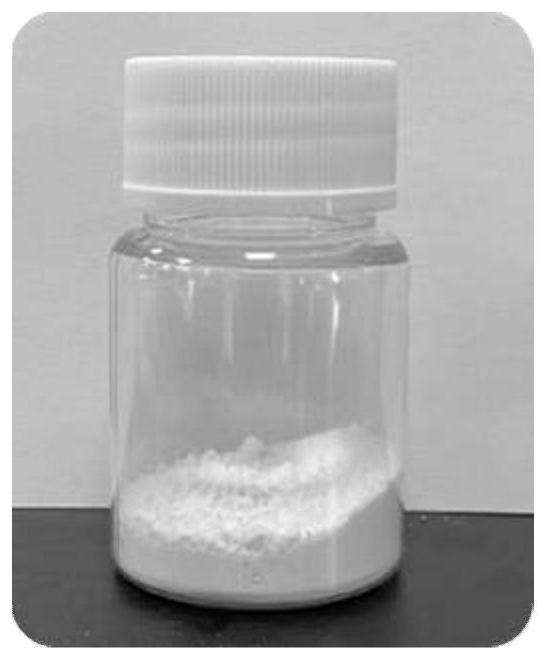

[0085] This embodiment provides a special powder thickener for 3D reactive printing and dyeing, and the preparation method includes the following steps:

[0086] Dissolve 60g of acrylic acid in water, add 32% liquid caustic soda dropwise to neutralize under chilled water circulation, and the degree of neutralization is 75%; then add 1.8g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 1.2g N,N methylenebisacrylamide (MBAA), 1.2g OP-10 and 10% ammonium persulfate aqueous solution, then add a certain amount of water as the water phase; subsequently, add 1.2g Span60, 1.2g of lauryl methacrylate (SMA) and cyclohexane were used as the oil phase to ensure that the oil-water ratio was 1.5:1; then the water phase was added to the oil phase and stirred rapidly to make it emulsified completely, and nitrogen was introduced for deoxygenation for about 1h ; After a certain period of nitrogen, the temperature was raised to 70 °C to initiate polymerization. After the reaction, the produ...

Embodiment 2

[0088] Basically the same as Example 1, only the degree of neutralization was changed to 90%.

Embodiment 3

[0090] Basically the same as Example 1, only the degree of neutralization was changed to 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com