Copper ferrite spinel material as well as preparation method and application thereof

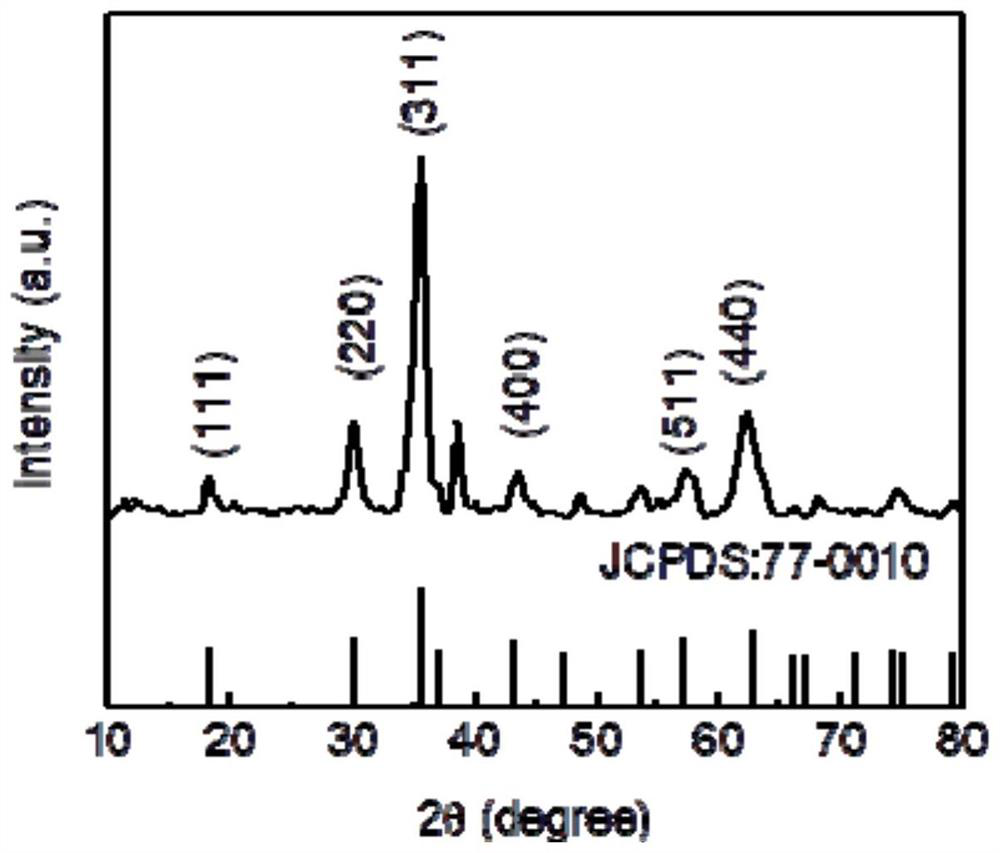

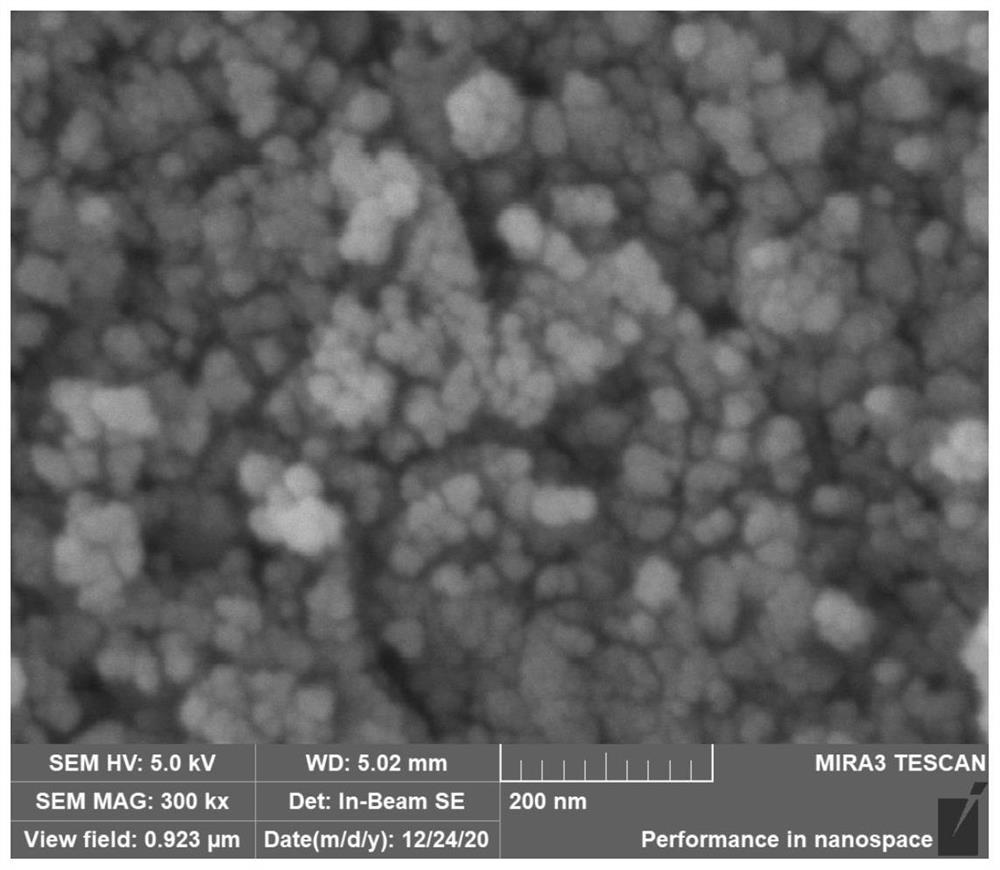

A technology of copper ferrite and spinel, applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of large dosage of copper ferrite , the dissolution of metal copper ions and the poor reusability of materials, etc., to achieve the effect of stable crystal structure, good crystallization and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of copper ferrite spinel material:

[0033] According to the chemical formula CuFe 2 o 4 The stoichiometric ratio of each element in the formula, respectively weighed raw materials: Fe(NO3) 3 9H 2 O: 4.04 g, Cu(NO 3 ) 2 ·3H 2 O: 1.28 grams, citric acid: 3.15 grams.

[0034] Cu(NO 3 ) 2 ·3H 2 O and Fe(NO3) 3 9H 2 Dissolve O in a flask filled with 100mL ultrapure water, and stir in a water bath at 60°C; dissolve citric acid powder in 100mL pure water, and add it dropwise to the salt solution with a separatory funnel, and the mixed solution continues to cool at 50°C to 60°C Stir in a water bath for 2h-4h; then adjust the temperature of the water bath to 80-90°C, continue stirring to evaporate water; transfer the obtained transparent sol into an oven, and dry at 100°C-105°C for 10-16h to obtain a gel; Transfer to a muffle furnace and calcinate for a certain period of time (rise temperature at 1°C / min from room temperature to 200°C, keep at 200°C for ...

Embodiment 2

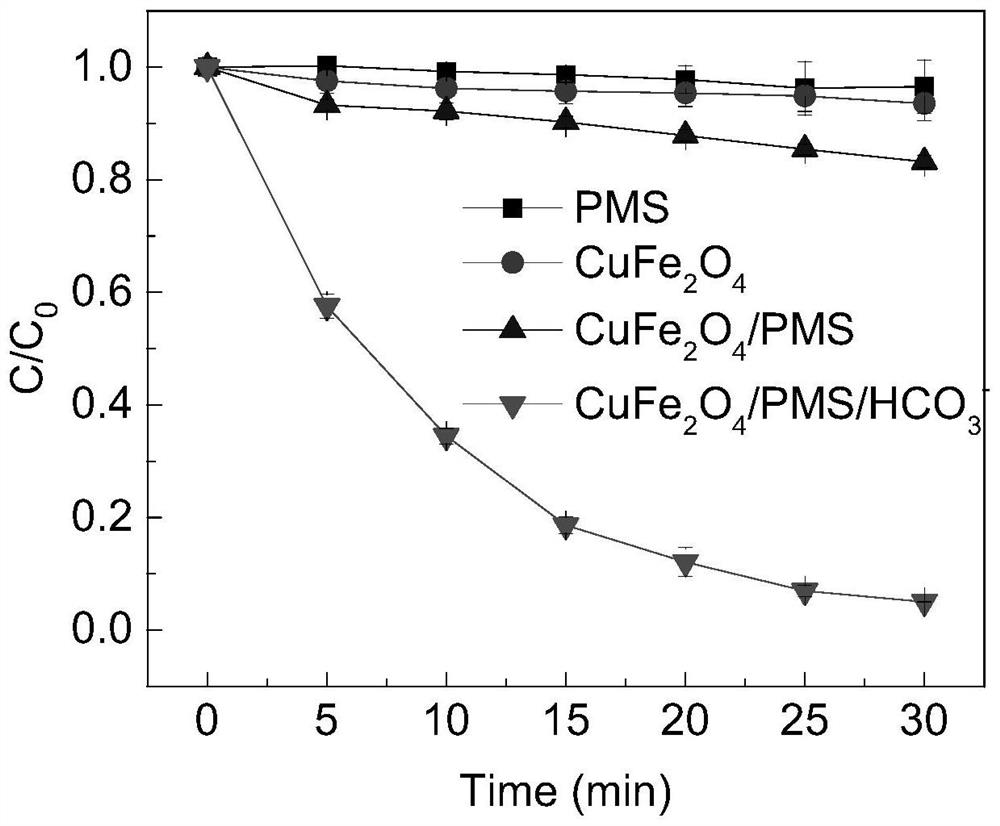

[0038] The copper ferrite spinel material prepared in Example 1 was applied to the research on the removal of yellow orange II (AO7).

[0039] Test 1: Take 100 mL of Orange II solution with a concentration of 0.29 mM, add copper ferrite spinel material in an amount of 0.63 mM, and react at room temperature for 30 min.

[0040] Test 2: Take 100 mL of orange II solution with a concentration of 0.29 mM, add peroxymonosulfate in an amount of 0.98 mM, and react at room temperature for 30 min.

[0041] Test 3: Take 100mL of Orange II solution with a concentration of 0.29mM, add copper ferrite spinel material in an amount of 0.63mM, add peroxymonosulfate in an amount of 0.98mM, and react at room temperature for 30min.

[0042] Test 4: Take 100mL of orange II solution with a concentration of 0.29mM, add copper ferrite spinel material in an amount of 0.63mM, add persulfate in an amount of 0.98mM, add 2mM bicarbonate, and react at room temperature for 30min .

[0043] like image 3 S...

Embodiment 3

[0045] The peroxosulfate / bicarbonate / copper ferrite spinel material system was applied to the research of treating different organic pollutants.

[0046] Test 5: Take 100mL of Orange II solution with a concentration of 0.2mM, add copper ferrite spinel material in an amount of 0.15g / L, add peroxymonosulfate in an amount of 0.3g / L, and add 2mM bicarbonate, React at room temperature for 30 minutes.

[0047] Test 6: Take 100mL of rhodamine B solution with a concentration of 0.2mM, add copper ferrite spinel material in an amount of 0.15g / L, add peroxymonosulfate in an amount of 0.3g / L, and add 2mM bicarbonate , reacted at room temperature for 30min.

[0048] Test 7: Take 100mL of reactive brilliant blue solution with a concentration of 0.2mM, add copper ferrite spinel material in an amount of 0.15g / L, add peroxymonosulfate in an amount of 0.3g / L, and add 2mM bicarbonate , reacted at room temperature for 30min.

[0049] Test 8: Take 100mL of methyl orange solution with a concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com