Shape memory alloy hollow micro-lattice material and preparation method thereof

A technology of memory alloy and micro-lattice, which is applied in the field of micro-lattice materials to achieve the effects of good film uniformity, wide selection of materials, and good memory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A shape-memory alloy hollow micro-lattice material, the formula includes: NiTi alloy with equiatomic ratio, and the weight percentage of the component is: 100% NiTi alloy.

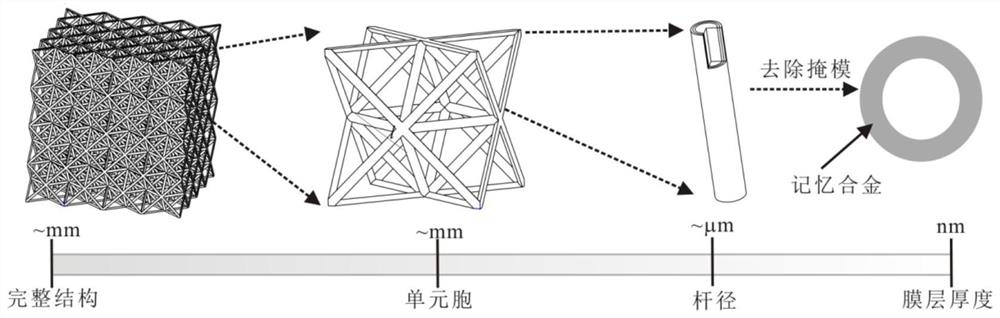

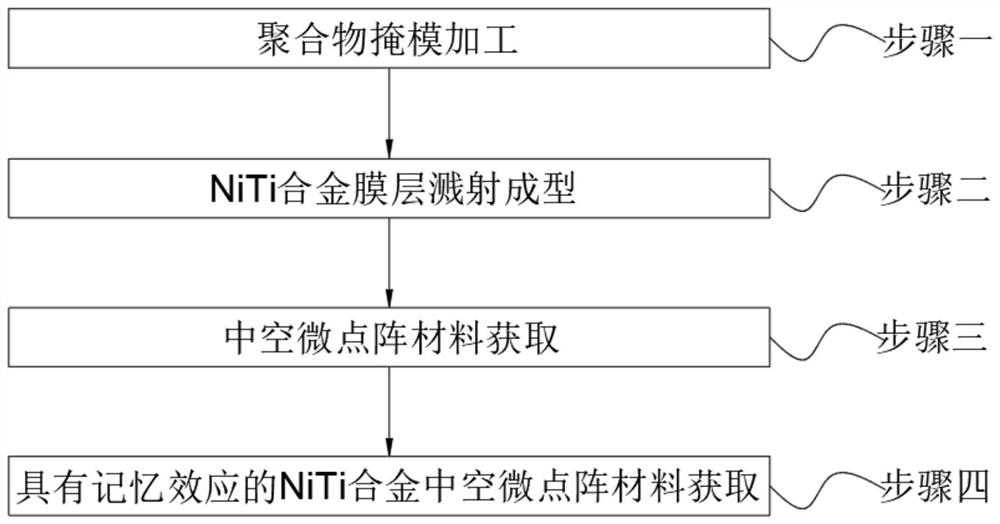

[0022] A method for preparing a shape memory alloy hollow micro-lattice material, comprising step 1, polymer mask processing; step 2, NiTi alloy film layer sputtering forming; step 3, hollow micro-lattice material acquisition; step 4, having memory Effect of NiTi alloy hollow micro-lattice material acquisition;

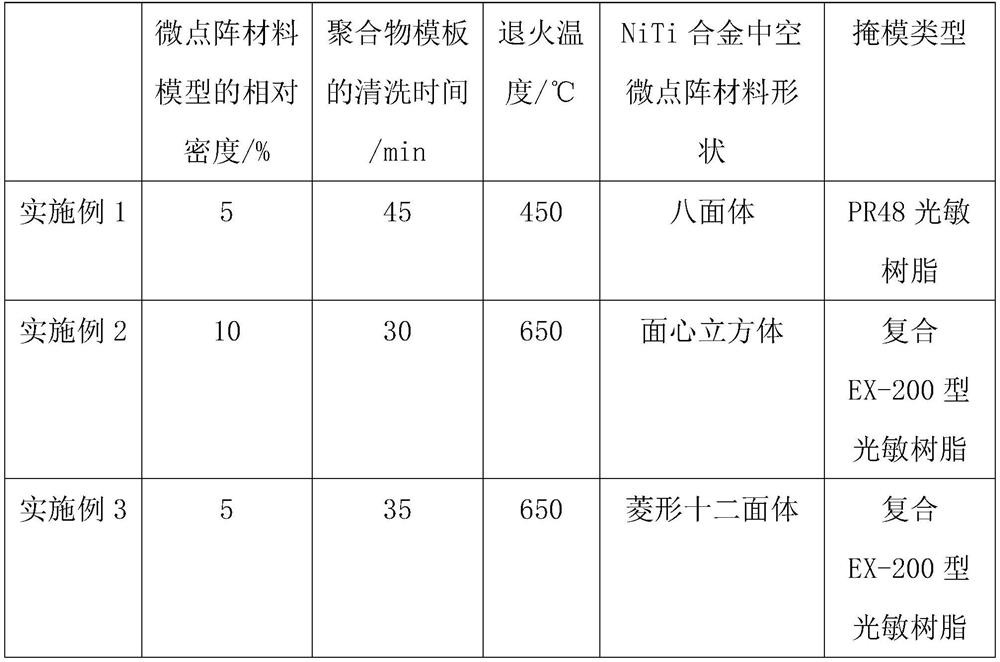

[0023] In the above step 1, first establish a micro-array material model with a relative density of 5% and a unit rod diameter of 0.1mm through CAD software, then convert the CAD file into an STL format file, and then import the STL format file into the 3D printing device , using digital light processing technology to process PR48 photosensitive resin octahedral micro-lattice material mask; the process parameters are projection resolution 768×480, projection light band 350nm, slice thicknes...

Embodiment 2

[0028] A shape-memory alloy hollow micro-lattice material, the formula includes: NiTi alloy, and the weight percentage of the component is: 100% NiTi alloy.

[0029] A method for preparing a shape memory alloy hollow micro-lattice material, comprising step 1, polymer mask processing; step 2, NiTi alloy film layer sputtering forming; step 3, hollow micro-lattice material acquisition; step 4, having memory Effect of NiTi alloy hollow micro-lattice material acquisition;

[0030] In the above step 1, first establish a micro-array material model with a relative density of 10% and a unit rod diameter of 0.2mm through CAD software, then convert the CAD file into an STL format file, and then import the STL format file into the 3D printing device , using digital light processing technology to process composite EX-200 photosensitive resin material face-centered cube micro-lattice material mask; process parameters are ultraviolet laser 355nm, scanning speed 300mm / s, scanning distance 0.3...

Embodiment 3

[0035] A shape-memory alloy hollow micro-lattice material, the formula includes: NiTi alloy, and the weight percentage of the component is: 100% NiTi alloy.

[0036] A method for preparing a shape memory alloy hollow micro-lattice material, comprising step 1, polymer mask processing; step 2, NiTi alloy film layer sputtering forming; step 3, hollow micro-lattice material acquisition; step 4, having memory Effect of NiTi alloy hollow micro-lattice material acquisition;

[0037] In the above step 1, first establish a micro-array material model with a relative density of 5% and a unit rod diameter of 0.1mm through CAD software, then convert the CAD file into an STL format file, and then import the STL format file into the 3D printing device , using digital light processing technology to process composite EX-200 photosensitive resin material rhombic dodecahedron micro-lattice material mask; process parameters are ultraviolet laser 355nm, scanning speed 300mm / s, scanning distance 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com