Exterior wall fireproof coating and preparation method thereof

A technology for fire retardant coatings and exterior walls, which can be used in fire retardant coatings, cement coatings, coatings, etc., and can solve problems such as poor fire performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

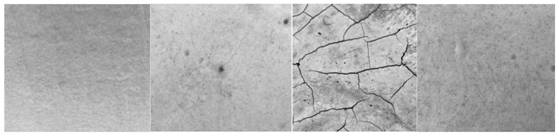

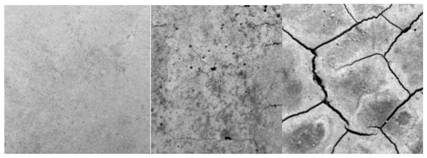

Image

Examples

Embodiment 1

[0037] A fireproof coating for exterior walls, comprising the following components in parts by weight:

[0038] 7 parts of styrene-acrylic emulsion;

[0039] 7 parts of water-based epoxy emulsion;

[0040] 45 parts of 525 high alumina cement;

[0041] 4 parts of aluminum silicate refractory fiber;

[0042] 0.5 parts of vinyltriethoxysilane;

[0043] 4 parts of silica sol.

[0044] Wherein, the aluminum silicate refractory fibers are chopped fibers with an average diameter of 2.5-3.5 μm and a fiber length of 3 mm.

[0045] The solid content of the water-based epoxy emulsion is 50%, and the epoxy equivalent is 1150.

[0046] The solid content of the styrene-acrylic emulsion is 48%, and the viscosity at 25° C. is 700 cps.

[0047] The preparation process is as follows: pre-disperse aluminum silicate refractory fiber and silane coupling agent into styrene-acrylic emulsion to obtain styrene-acrylic emulsion mixture, mix silica sol into high-alumina cement to obtain high-alumi...

Embodiment 2

[0049] A fireproof coating for exterior walls, comprising the following components in parts by weight:

[0050] 5 parts of styrene-acrylic emulsion;

[0051] 10 parts of water-based epoxy emulsion;

[0052] 35 parts of 525 high alumina cement;

[0053] 5 parts of aluminum silicate refractory fiber;

[0054] 0.2 parts of vinyltrimethoxysilane;

[0055] 3 parts of silica sol.

[0056] Wherein, the aluminum silicate refractory fibers are chopped fibers with an average diameter of 2.5-3.5 μm and a fiber length of 3 mm.

[0057] The solid content of the water-based epoxy emulsion is 50%, and the epoxy equivalent is 1150.

[0058] The solid content of the styrene-acrylic emulsion is 48%, and the viscosity at 25° C. is 700 cps.

[0059] The preparation method is the same as in Example 1.

Embodiment 3

[0061] A fireproof coating for exterior walls, comprising the following components in parts by weight:

[0062] 10 parts of styrene-acrylic emulsion;

[0063] 5 parts of water-based epoxy emulsion;

[0064] 40 parts of 625 high alumina cement;

[0065] 4 parts of aluminum silicate refractory fiber;

[0066] 0.8 parts of vinyltrimethoxysilane;

[0067] 5 parts of silica sol.

[0068]Wherein, the aluminum silicate refractory fiber is chopped fiber with an average diameter of 2.5-3.5 μm and a fiber length of 2 mm.

[0069] The solid content of the water-based epoxy emulsion is 50%, and the epoxy equivalent is 1150.

[0070] The solid content of the styrene-acrylic emulsion is 48%, and the viscosity at 25° C. is 700 cps.

[0071] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com