Dry material anti-oxidation coating for continuous casting tundish

An anti-oxidation coating and continuous casting technology, applied in the field of refractory coating, can solve the problems affecting the safety performance of the tundish, reducing the strength of dry materials, loose structure, etc. Strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

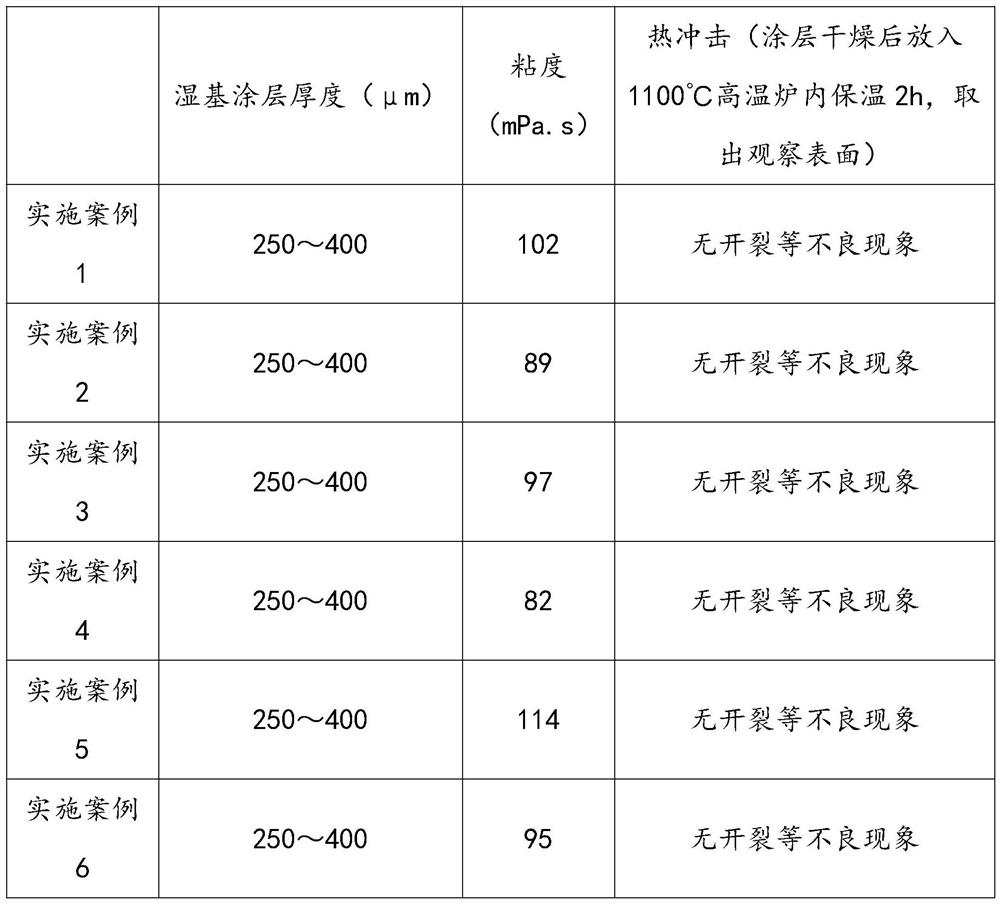

Examples

Embodiment example 1

[0049] Weigh 17 parts of medium temperature glass powder, 6 parts of solid water glass, 34 parts of lightly burned magnesium powder, 1.3 parts of terpineol, 2.5 parts of ethyl cellulose, 3.2 parts of water-based epoxy resin, 4 parts of sodium metasilicate nonahydrate, Silicon carbide scrap 32 parts, MoSi 2 30 parts of powder, B 2 o 3 30 parts of powder, SiO 2 25 parts of powder, 50 parts of isopropanol, 30 parts of chloroplatinic acid powder, 45 parts of absolute ethanol, 15 parts of polycarbosilane solution, 18 parts of dilute ammonia solution and 57 parts of deionized water;

[0050] Send the light-burned magnesium powder and water-based epoxy resin into the planetary ball mill, vibrate and grind for 80 minutes at a speed ratio of 1:1.5, and then send it to a vacuum drying furnace for heating and drying. For 25 minutes, the heating temperature is 95°C, and the mixed powder is obtained. The particle size of the mixed powder is 600 mesh. Put the medium temperature glass pow...

Embodiment example 2

[0053] Weigh 18 parts of medium temperature glass powder, 5 parts of solid water glass, 33 parts of lightly burned magnesium powder, 1 part of terpineol, 2 parts of ethyl cellulose, 3 parts of water-based epoxy resin, 3 parts of sodium metasilicate nonahydrate, Silicon carbide scrap 35 parts, MoSi 2 30 parts of powder, B 2 o 3 30 parts of powder, SiO 2 25 parts of powder, 50 parts of isopropanol, 30 parts of chloroplatinic acid powder, 45 parts of absolute ethanol, 15 parts of polycarbosilane solution, 18 parts of dilute ammonia solution and 56 parts of deionized water;

[0054] Send the light-burned magnesium powder and water-based epoxy resin into the planetary ball mill, vibrate and grind for 80 minutes at a speed ratio of 1:1.5, and then send it to a vacuum drying furnace for heating and drying. For 25 minutes, the heating temperature is 95°C, and the mixed powder is obtained. The particle size of the mixed powder is 600 mesh. Put the medium temperature glass powder, si...

Embodiment example 3

[0057]Weigh 16 parts of medium temperature glass powder, 8 parts of solid water glass, 31 parts of lightly burned magnesium powder, 1.5 parts of terpineol, 3 parts of ethyl cellulose, 3 parts of water-based epoxy resin, 3.5 parts of sodium metasilicate nonahydrate, Silicon carbide scrap 34 parts, MoSi 2 30 parts of powder, B 2 o 3 30 parts of powder, SiO 2 25 parts of powder, 50 parts of isopropanol, 30 parts of chloroplatinic acid powder, 45 parts of absolute ethanol, 15 parts of polycarbosilane solution, 18 parts of dilute ammonia solution and 58 parts of deionized water;

[0058] Send the light-burned magnesium powder and water-based epoxy resin into the planetary ball mill, vibrate and grind for 80 minutes at a speed ratio of 1:1.5, and then send it to a vacuum drying furnace for heating and drying. For 25 minutes, the heating temperature is 95°C, and the mixed powder is obtained. The particle size of the mixed powder is 600 mesh. Put the medium temperature glass powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com