Untwisted yarn towel

A technology of untwisted yarn and towel, which is applied in the field of untwisted yarn towels, which can solve the problems of short service life, short service life and waste of resources of untwisted yarn towels, and achieve the goal of maintaining strength, increasing strength and service life, and increasing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

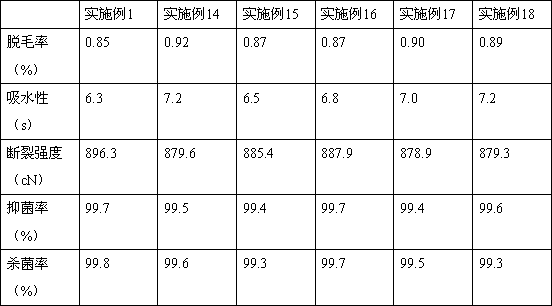

Examples

Embodiment 1

[0041] A kind of untwisted yarn towel, processing method comprises the steps:

[0042] (1) The vinylon and the yarn are twisted in reverse to form a cotton-dimensional ply yarn, and the cotton ply yarn is used as the warp thread, and the silver ion cotton yarn is used as the weft thread for weaving. The warp density is 250 threads / 10cm, and the weft density is 200 threads / 10cm. The silver ion cotton yarn is subjected to silver ion blockade treatment before weaving, so that the silver ion content in the silver ion cotton yarn is 10%.

[0043] Silver ion blockade treatment steps are as follows:

[0044] A. Soak the silver ion cotton yarn in the treatment solution, the bath ratio is 1:8, the temperature is 50°C, soak for 1h. The solvent of the treatment liquid is water and 5% OWF stabilizer and 12% OWF metal blocking agent are added. The metal blocking agent is a water-soluble chitin blocking agent. The stabilizer is water-soluble polyethylene glycol with a molecular weight o...

Embodiment 2

[0052] The difference between Example 2 and Example 1 is that the conditions of silver ion blocking treatment and the content of silver ions in the obtained silver ion cotton yarn are different, and the content of silver ion in the silver ion cotton yarn is 8%.

[0053] Silver ion blockade treatment steps are as follows:

[0054]A. Soak the silver ion cotton yarn in the treatment solution, the bath ratio is 1:9, the temperature is 50°C, soak for 1h. The solvent of the treatment liquid is water and 4% OWF stabilizer and 10% OWF metal blocking agent are added. The metal blocking agent is a water-soluble chitin blocking agent. The stabilizer is water-soluble polyethylene glycol with a molecular weight of 8000;

[0055] B. Add 4% OWF soaping agent to the treatment solution of step A, stir at 100-120r / min, and dehydrate;

[0056] C, the silver ion cotton yarn dehydrated in step B is soaked with clear water and then cleaned, the bath ratio is 1:25, soaked and cleaned 5 times and ...

Embodiment 3

[0058] The difference between Example 3 and Example 1 is that the conditions of silver ion blocking treatment and the content of silver ions in the obtained silver ion cotton yarn are different, and the content of silver ion in the silver ion cotton yarn is 7%.

[0059] Silver ion blockade treatment steps are as follows:

[0060] A. Soak the silver ion cotton yarn in the treatment solution, the bath ratio is 1:10, the temperature is 50°C, soak for 1h. The solvent of the treatment liquid is water and 3% OWF stabilizer and 8% OWF metal blocking agent are added. The metal blocking agent is a water-soluble chitin blocking agent. The stabilizer is water-soluble polyethylene glycol with a molecular weight of 2000;

[0061] B. Add 2% OWF soaping agent to the treatment solution of step A, stir at 100-120r / min, and dehydrate;

[0062] C. The silver ion cotton yarn dehydrated in step B is soaked and cleaned with clear water, the bath ratio is 1:20, soaked and cleaned 5 times and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com