Anaerobic ammonium oxidation bacteria particle culture method and device

An anammox bacteria and culture method technology, applied in the field of environmental protection microorganisms, can solve the problems of easy bonding of fiber fillers into agglomerates, inability to achieve a mixed state, poor solid-liquid contact effect, etc. Expand training and reduce the effect of manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

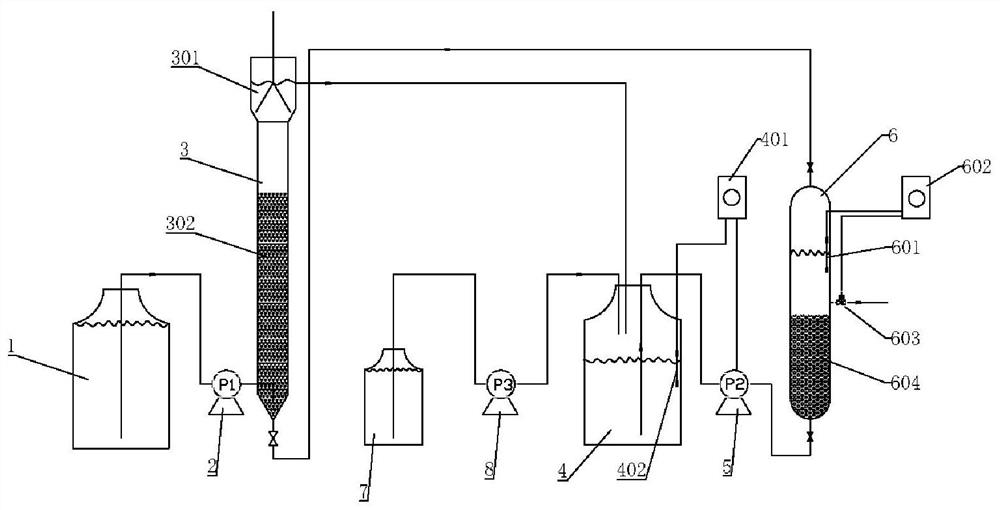

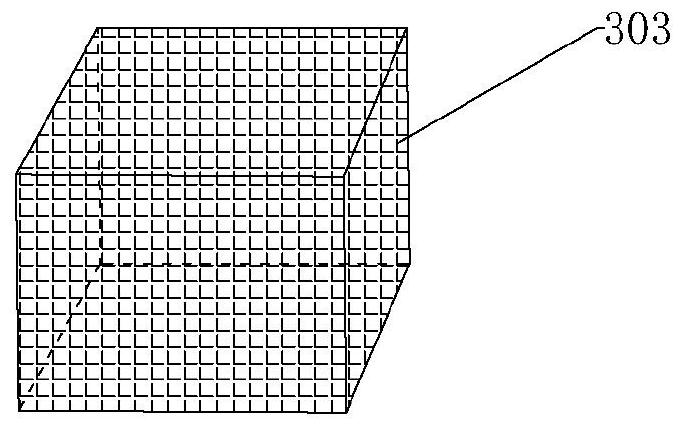

[0031] see Figure 1-2 , as a typical embodiment of the present invention, a kind of anammox bacterial granule culture device, comprises enrichment nutrient solution tank 1, upflow anaerobic reactor 3, first water pump 2, medium storage tank 4, the second Two water pumps 5 and the denitrification reactor 6, the upflow anaerobic reactor 3, the middle storage tank 4 and the denitrification reactor 6 are connected in sequence; The oxygen reactor 3 is connected through the first water pump 2, and the top of the upflow reactor 3 is provided with a three-phase separator 301, and the three-phase separator 301 is provided with a liquid outlet, and the liquid outlet is connected to the middle through a pipeline. The storage tank 4 is connected, and the middle storage tank 4 is connected with the denitrification reactor 6 through the second water pump 5. The top of the denitrification reactor 6 is provided with a gas outlet, and the gas outlet is connected to the upflow type via a gas p...

Embodiment 1

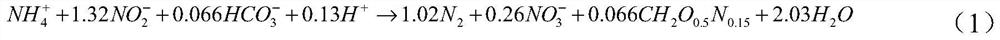

[0038] A method for cultivating anaerobic ammonium oxidizing bacteria granules, comprising the steps of:

[0039] S1. Using domestic sewage as the influent, mix granular fillers and nitrification sludge for intermittent aeration culture, set the aeration temperature to 20°C, and the dissolved oxygen concentration to 2 mg / L, and stop the aeration after 6 hours of air aeration. Place the sediment for 0.5h, discharge the supernatant after standing, add the same volume of water and let stand for 3h, this is an aeration culture cycle; repeat the culture cycle to more than 20 days to complete the intermittent aeration culture of granular fillers;

[0040] S2. Fill the granular filler obtained in step S1 after intermittent aeration culture into the hollow carrier on the mesh surface as a film-hanging filler layer and place it in the anaerobic reactor, put in nitrification sludge, and feed the enriched nutrient solution to start the anaerobic reactor. Oxygen ammonium oxidation culture...

Embodiment 2

[0050] A method for cultivating anaerobic ammonium oxidizing bacteria granules, comprising the steps of:

[0051] S1. Using domestic sewage as the influent, mix granular fillers and nitrifying sludge for intermittent aeration culture, set the aeration temperature to 30°C, and the dissolved oxygen concentration to 3 mg / L, and stop the aeration after 7 hours of air aeration. Place the sediment for 1 hour, discharge the supernatant after standing, add the same volume of water and let stand for 4 hours, this is an aeration culture cycle; repeat the culture cycle to 20 days to complete the intermittent aeration culture of granular fillers;

[0052] S2. Fill the granular filler obtained in step S1 after intermittent aeration culture into the hollow carrier on the mesh surface as a film-hanging filler layer and place it in the anaerobic reactor, put in nitrification sludge, and feed the enriched nutrient solution to start the anaerobic reactor. Oxygen ammonium oxidation culture;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com