Formula, preparation method and application of CsPbBr3: xDy < 3 + > quantum dot glass

A quantum dot glass and quantum dot technology, which are used in glass manufacturing equipment, glass molding, chemical instruments and methods, etc., can solve the problems of low crystallinity and unfriendly environment of quantum dots, achieve uniform particle size and improve crystallinity. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The raw material purity used for the following implementation of the present invention is as follows:

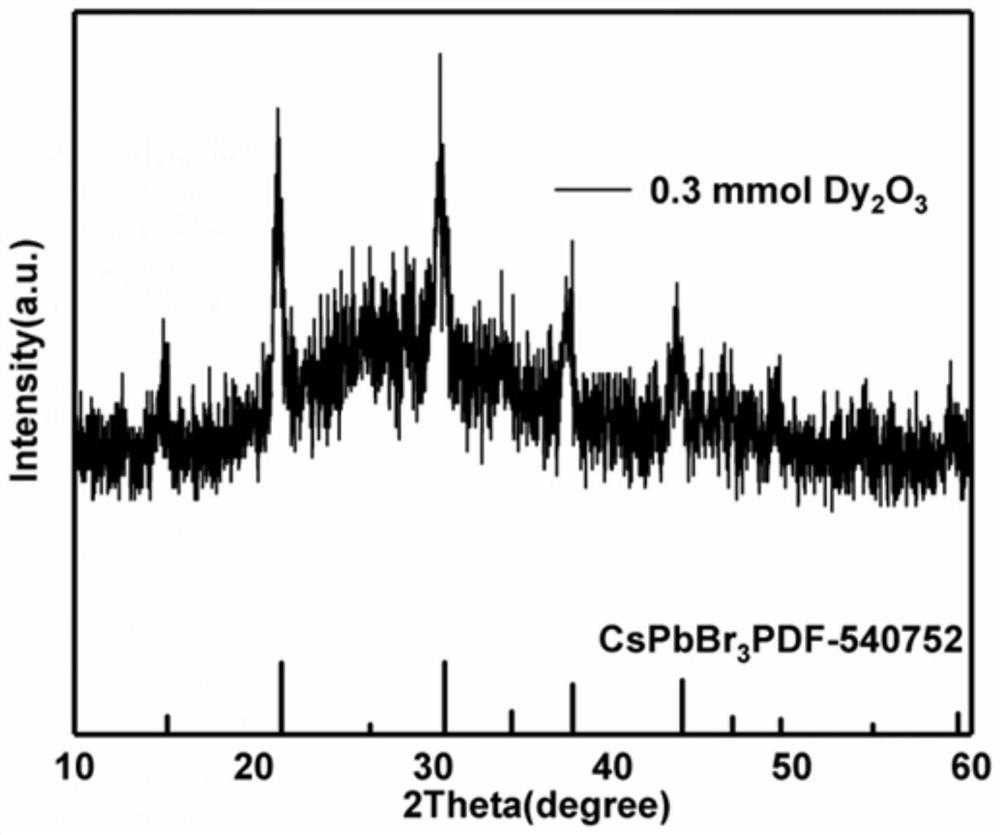

[0038] Sodium carbonate (≥99.5%), barium titanate (99%), silicon dioxide (99.5%), zinc oxide (99%), boric acid (≥99.5%), dysprosium oxide (≥99%), cesium carbonate (99.99%) %), lead oxide (≥99%), sodium bromide (99%). Glass matrix according to molar mass 5Na 2 CO 3 -20ZnO-80H 3 BO 3 -15SiO2 2 -10BaCO 3 Proportioning; doping materials according to molar mass xDy 2 o 3 (x=0.3mol%) for proportioning; the quantum dot raw material is according to the molar mass of 1.5Cs 2 CO 3 -3PbO-9NaBr (mol%) for proportioning.

[0039] Prepare a CsPbBr as follows 3 :xDy 3+ Quantum dot glass:

[0040] (1) Weigh the raw materials according to the above molar mass, then add them to the agate grinding pot in batches, and fully grind them with a grinding rod.

[0041] (2) Transfer the fully ground raw material from the agate grinding pot to a corundum crucible, and then put the...

Embodiment 2

[0048] The raw material purity used for the following implementation of the present invention is as follows:

[0049] Sodium carbonate (≥99.5%), barium titanate (99%), silicon dioxide (99.5%), zinc oxide (99%), boric acid (≥99.5%), dysprosium oxide (≥99%), cesium carbonate (99.99%) %), lead oxide (≥99%), sodium bromide (99%). Glass matrix according to molar mass 5Na 2 CO 3 -20ZnO-80H 3 BO 3 -15SiO2 2 -10BaCO 3 Proportioning; doping materials according to molar mass xDy 2 o 3 (x=0.5mol%) for proportioning; the quantum dot raw material is according to the molar mass of 1.5Cs 2 CO 3 -3PbO-9NaBr (mol%) for proportioning.

[0050] Prepare a CsPbBr as follows 3 :xDy 3+ Quantum dot glass:

[0051] (1) Weigh the raw materials according to the above molar mass, then add them to the agate grinding pot in batches, and fully grind them with a grinding rod.

[0052] (2) Transfer the fully ground raw material from the agate grinding pot to a corundum crucible, and then put the...

Embodiment 3

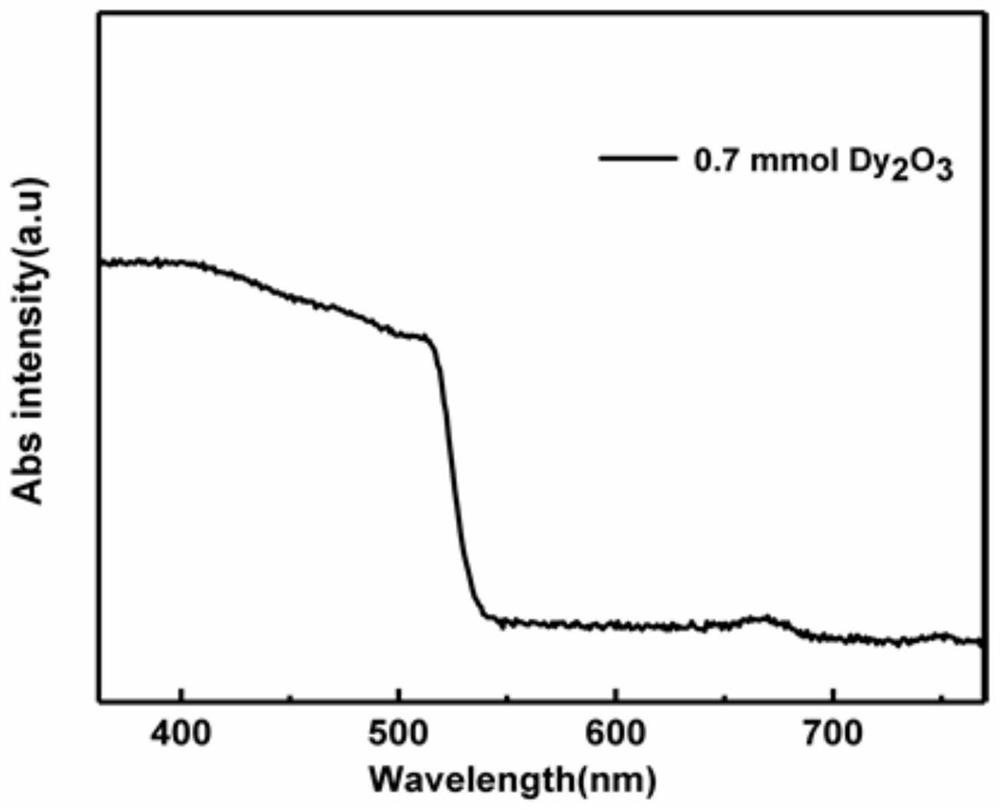

[0059] The raw material purity used for the following implementation of the present invention is as follows:

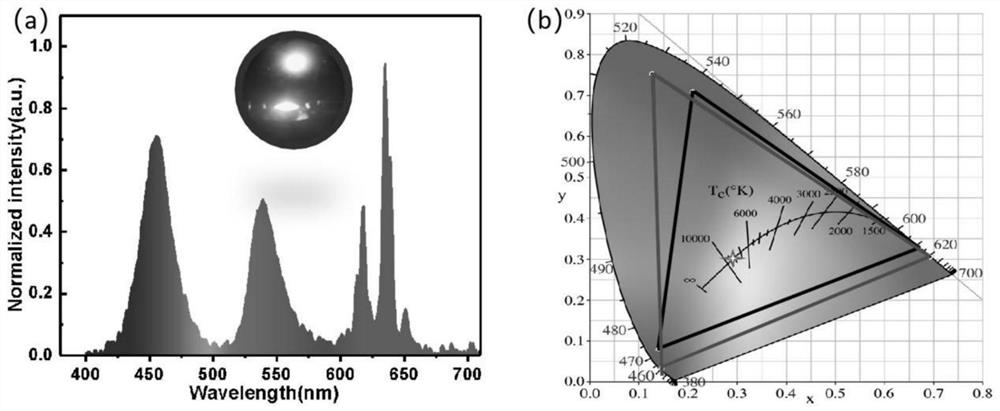

[0060] Glass matrix according to molar mass 5Na 2 CO 3 -20ZnO-80H 3 BO 3 -15SiO2 2 -10BaCO 3 Proportioning; doping materials according to molar mass xDy 2 o 3 (x=0.7mol%) for proportioning; the quantum dot raw material is 1.5Cs according to the molar mass 2 CO 3 -3PbO-9NaBr (mol%) for proportioning. The glue uses A / B glue, the ratio of A component and B component is 1:1, and the red commercial phosphor with emission wavelength of 630nm is used, and the red commercial phosphor and CsPbBr 3 :xDy 3+ The ratio of quantum dot glass powder is 1:3. A blue light chip with an emission wavelength of 450nm is used, and the rated power of the blue light chip is 1W.

[0061] Prepare a CsPbBr as follows 3 :xDy 3+ Quantum dot glass, and package it into a white LED device:

[0062] (1) Weigh the raw materials according to the above molar mass, then add them to the agat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com