Rib manufacturing device and method for continuous fiber reinforced thermoplastic composite rod

A technology of reinforced thermoplastic and composite materials, which is applied in the direction of household components, household appliances, and other household appliances. It can solve the problems of mechanical properties and durability decline, continuous preparation, and low bonding strength, etc., to achieve stable rib performance, Improved mechanical properties and service life, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

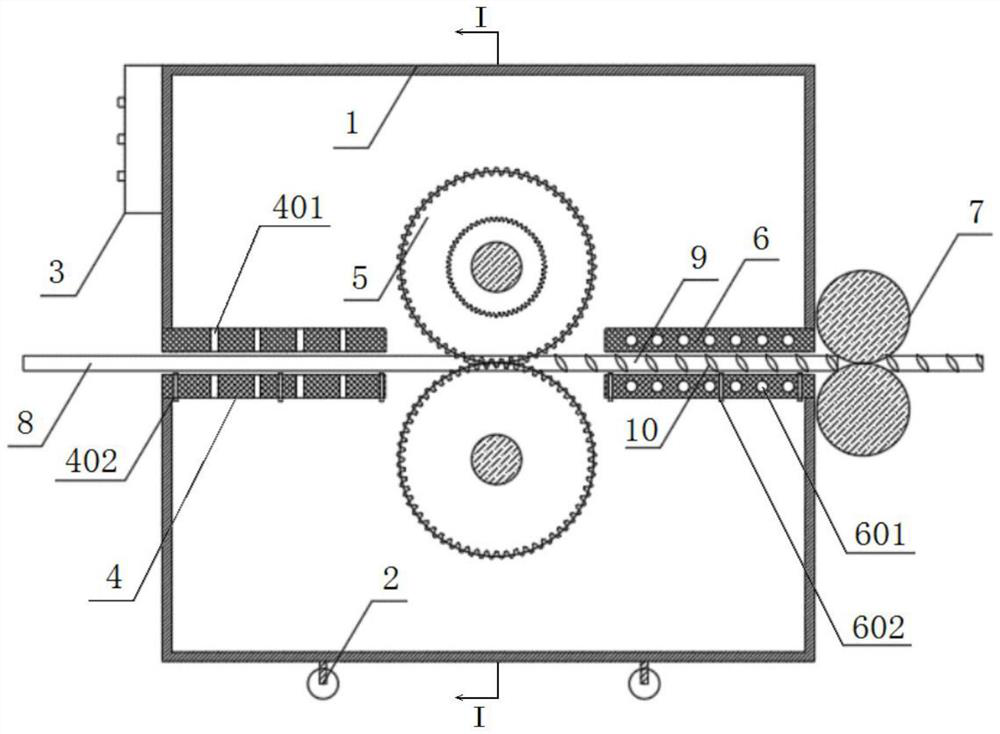

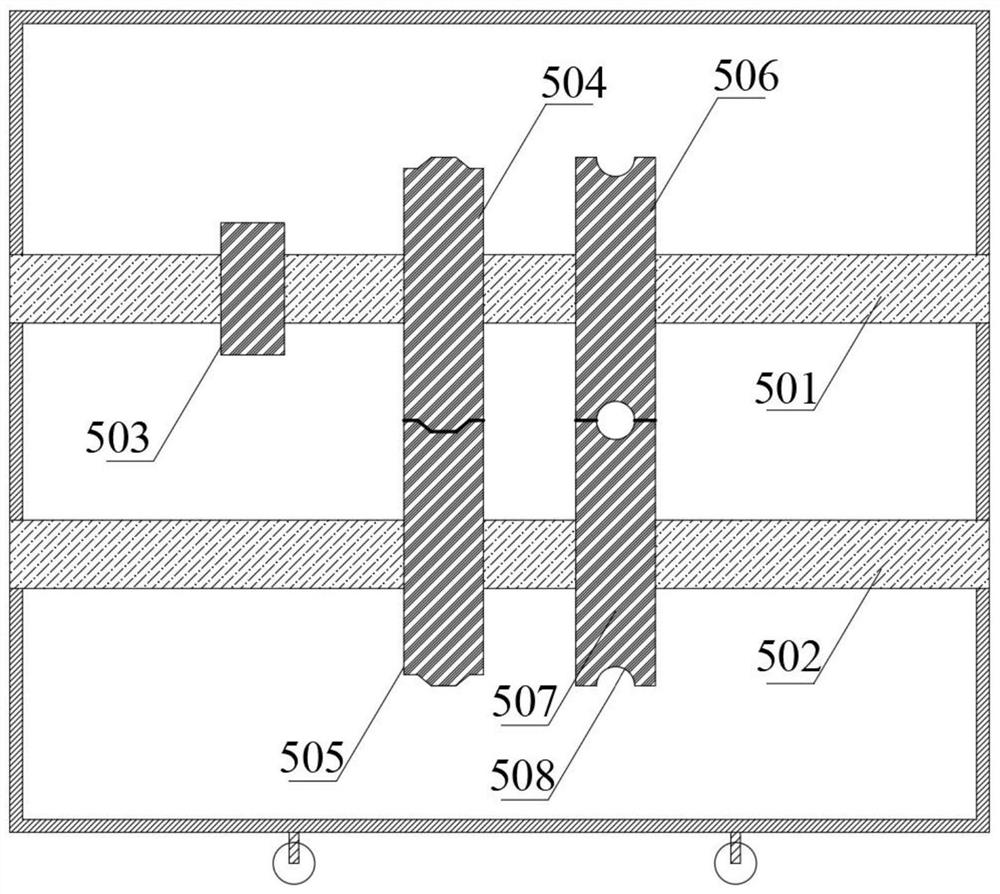

[0035] Embodiment 1. A continuous fiber reinforced thermoplastic composite rod rib making device in this embodiment includes moving rollers 2 arranged outside the steel frame 1, a control console 3, and traction rollers 7, as well as heating pipes arranged inside the steel frame 1. 4. Extrusion shaping part 5 and cooling pipe 6; the heating pipe 4 and cooling pipe 6 are respectively located on both sides of the extrusion shaping part 5, and the extrusion shaping part 5 and traction roller 7 are respectively located on the cooling pipe 6 On both sides of the steel frame 1, the heating pipe 4 and the cooling pipe 6 are respectively fixedly connected to the side walls of the steel frame 1;

[0036] The inside of the tube body of the heating tube 4 is evenly provided with a number of heating galvanic rods 401 and a number of high temperature sensors 402, the heating galvanic rods 401 and the high temperature sensors 402 are evenly arranged in the axial direction of the heating tube...

Embodiment 2

[0041] Embodiment 2, a method for making ribs of a continuous fiber-reinforced thermoplastic composite rod according to this embodiment is carried out in the following steps:

[0042] Step 1: Start the heating galvanic rod 401 on the heating tube 4 to make the temperature reach 180-400°C and keep it constant;

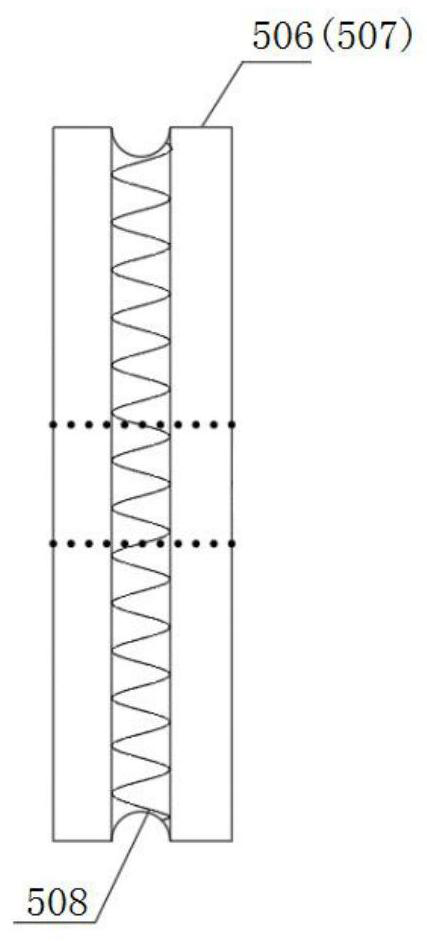

[0043] Step 2: Pass cooling water into the cooling pipe 6, start the servo motor of the extrusion shaping part 5, and adjust the rotation speed of the driving gear 503 through the console 3, so that the thread pitch on the continuous fiber reinforced thermoplastic composite rod is 4 mm to 16 mm , the allowable error is ±0.5mm, driven by the traction roller 7, the continuous fiber reinforced thermoplastic composite rod 8 passes through the extrusion shaping part 5 to obtain the CFRTP threaded rib 9, and the traction speed is divided into low speed and high speed, wherein the low speed is 0.1m / min~1.0m / min, the high speed is 1.0m / min~5.0m / min, the thermoplastic matrix mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com