Preparation method of nanoimprint anisotropic graphene film

A graphene film, anisotropic technology, applied in the field of preparation of anisotropic graphene film, can solve the problems of cumbersome calculation and mathematical calculation, complex operation steps, complex equipment, etc., and achieve complex preparation methods and good repeatability , Accurate and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

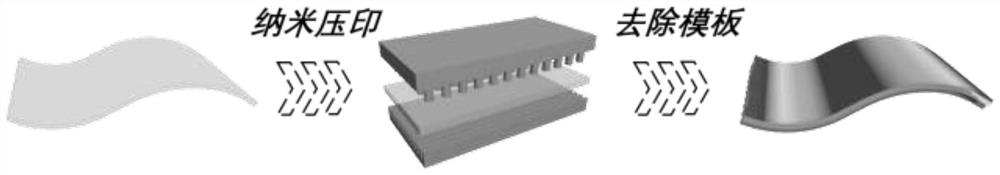

[0029] The invention provides a kind of preparation method of the anisotropic graphene film of nanoimprinting, comprises the steps:

[0030] 1) Preparation of graphene-doped polymer films: select thermoplastic polymers to be configured into a pre-gel solution of a certain concentration, and prepare the pre-gel solution into a film with a uniform surface by using spin coating and solvent evaporation methods, and then the The surface of the film is modified with polydopamine, and graphene oxide is adhered, and finally the graphene oxide is reduced with hydroiodic acid to obtain a graphene-doped polymer film;

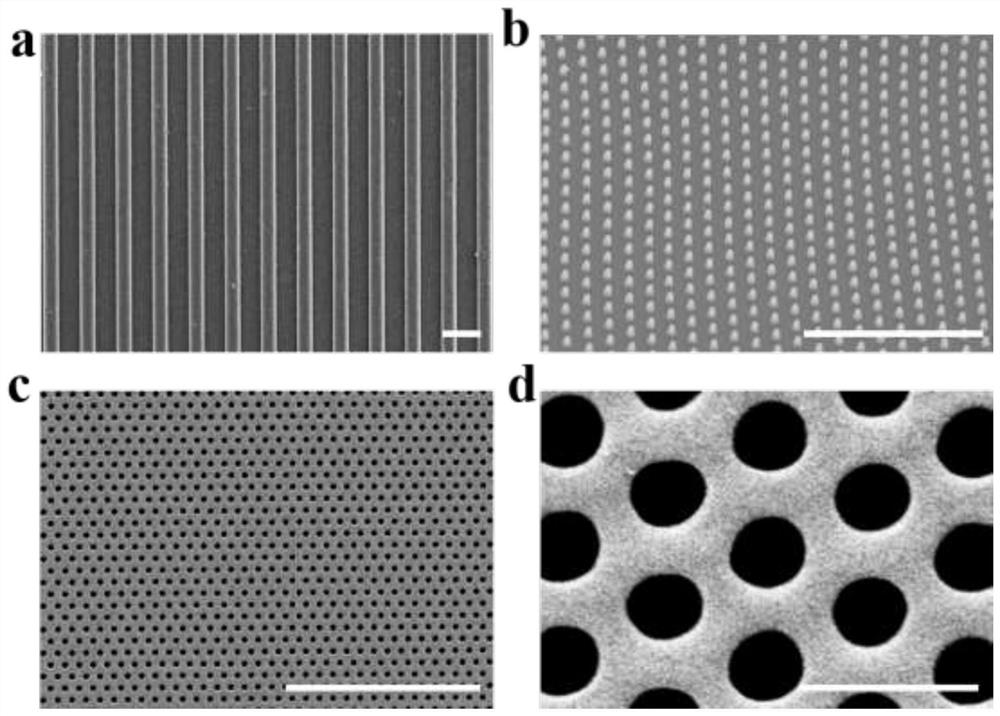

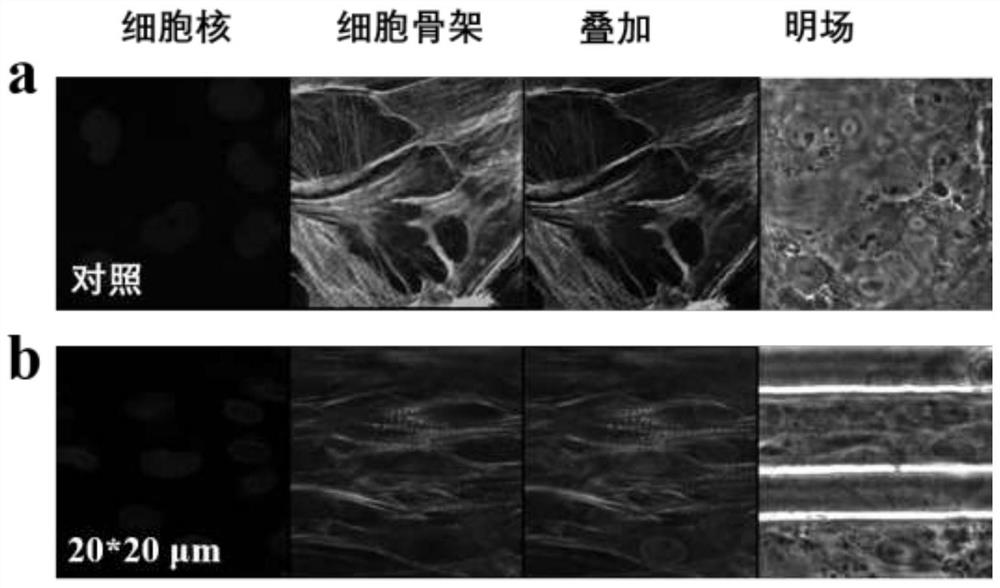

[0031] 2) Preparation of nanoimprinted anisotropic graphene film: use two PDMS positive templates with micron-scale grooves and nano-scale cylinders to sandwich the graphene-doped polymer film prepared in step 1) to form a " Sandwich" model, using a nanoimprinter to obtain a nanoimprinted anisotropic graphene film in one step.

[0032] Further, the thermoplastic polymer i...

Embodiment 1

[0043] A nanoimprinted anisotropic graphene film using nitrocellulose as a skeleton material, prepared according to the following method:

[0044] (1) Preparation of nitrocellulose pregel solution

[0045]The nitrocellulose powder was dissolved in a mixed solution of acetone and DMF (acetone:DMF=1:1, v / v), the final concentration was 7% (wt%), the mixed solution was placed on a magnetic stirrer, and mixed Stir until the nitrocellulose powder is completely dissolved, then, in order to increase the elasticity of the nitrocellulose film, add 2% Tween-20 to the mixed solution, and stir the solution evenly to obtain a nitrocellulose pregel solution.

[0046] (2) Preparation of nitrocellulose film grafted with graphene on the surface

[0047] The prepared nitrocellulose pregel solution was prepared into a thin film on the surface of a plasma-treated glass sheet by spin coating, and the film was heated on a hot stage at 65°C, and the film was cured by solvent volatilization, and the...

Embodiment 2

[0053] A nano-imprinted anisotropic graphene film using polyvinylidene fluoride as a framework material, prepared according to the following method:

[0054] (1) Preparation of polyvinylidene fluoride pregel solution

[0055] Dissolve polyvinylidene fluoride powder in DMF solution, final concentration is 7wt%, place this mixed solution on the magnetic stirrer, mix and stir until polyvinylidene fluoride powder dissolves completely, afterwards, in order to increase polyvinylidene fluoride film For elasticity, 2% Tween-20 is added to the mixed solution, and the solution is stirred evenly to obtain a polyvinylidene fluoride pregel solution.

[0056] (2) Preparation of polyvinylidene fluoride film grafted on the surface of graphene

[0057] The prepared polyvinylidene fluoride pregel solution is prepared into a thin film on the surface of a plasma-treated glass sheet by spin coating, and the film is heated on a hot stage at 65°C, and the film is cured by solvent volatilization. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com