Combined process method for producing olefin, aromatic hydrocarbon and mesophase pitch-based carbon fiber from crude oil

A mesophase pitch and carbon fiber technology, applied in the petroleum industry, hydroprocessing process, hydrocarbon oil treatment products, etc., can solve the problems of poor raw material adaptability and low chemical yield, and achieve strong adaptability and high chemical yield High, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

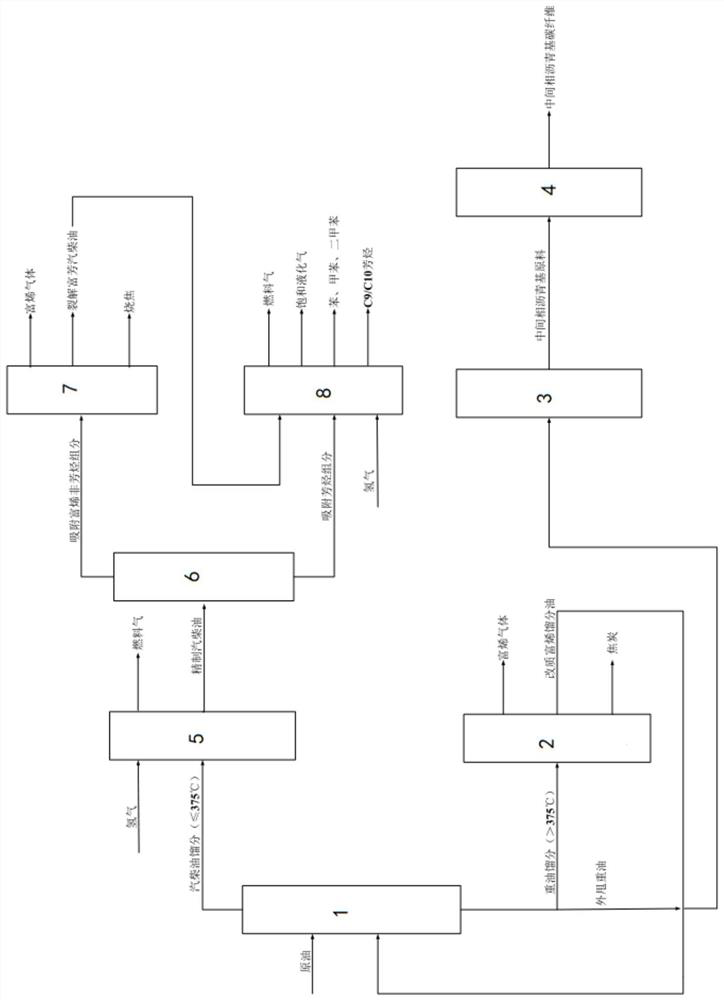

Image

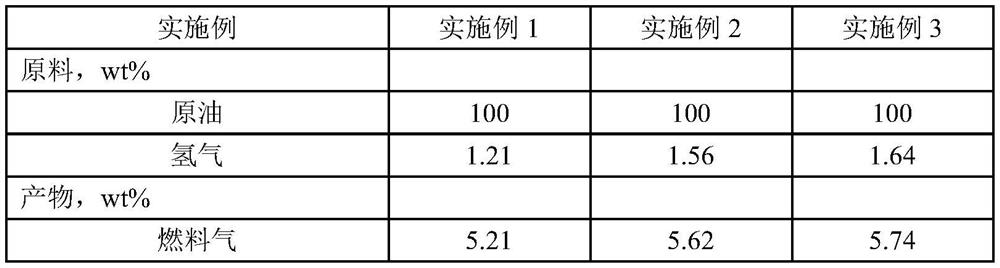

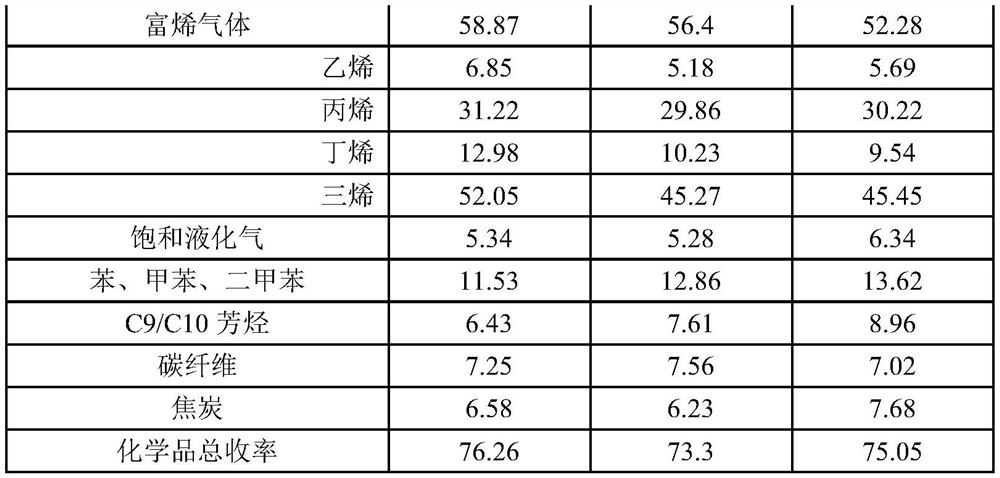

Examples

Embodiment 1

[0041] The paraffin-based crude oil from a refinery was used as the raw material, and the properties of the raw material are shown in Table 1.

[0042] Heavy oil directional upgrading unit: the reactor adopts a riser reactor, and the directional upgrading catalyst adopts Bi-Ca-K / coarse-pore silica gel (based on the catalyst, the Bi content is 2.5wt%, the Ca content is 5.0wt%, and the K content is 8.0wt%) %, the balance is coarse-porous silica gel), reaction conditions: temperature 580°C, pressure 0.1MPa, steam / oil mass ratio 1.0:1.

[0043] Gasoline and diesel selective hydrofining unit: the catalyst uses Ni-Mo / macroporous alumina (based on the catalyst, the Ni content is 8wt%, the Mo content is 4.0wt%, and the balance is macroporous alumina), and the reaction conditions are: temperature 120℃, pressure 3.0MPa, mass space velocity 2.0h -1 , The volume ratio of hydrogen to oil is 600:1.

[0044] Gasoline and diesel adsorption separation unit: simulated moving bed process is ad...

Embodiment 2

[0051] The intermediate base crude oil from a refinery is used as the raw material, and the properties of the raw material are shown in Table 1.

[0052] Heavy oil directional upgrading unit: the reactor adopts a dense-phase fluidized bed, and the directional upgrading catalyst adopts Bi-Ca-K / silica (based on the catalyst, the Bi content is 4.0wt%, the Ca content is 10.0wt%, and the K content is 5.0 wt%, the balance is white carbon black), reaction conditions: temperature 480°C, pressure 0.2MPa, steam / oil mass ratio 2.0:1.

[0053] Gasoline and diesel selective hydrofining unit: the catalyst uses Ni-Co / amorphous silica-alumina + alumina (based on the catalyst, Ni content is 10wt%, Co content is 4.0wt%, and the balance is amorphous silica-alumina + alumina) , the reaction conditions are: temperature 140°C, pressure 3.0MPa, mass space velocity 1.5h -1 , The volume ratio of hydrogen to oil is 500:1.

[0054] Gasoline and diesel adsorption separation unit: fixed bed technology i...

Embodiment 3

[0061] Naphthenic crude oil from a refinery is used as raw material, and the properties of the raw material are shown in Table 1.

[0062] Heavy oil directional reforming unit: the reactor adopts moving bed, and the directional reforming catalyst adopts Ce-Ca-Mg / high silicon MCM-48 molecular sieve (based on the catalyst, Ce content is 3.0wt%, Ca content is 15.0wt%, Mg content is 3.0wt%) %, the balance is molecular sieve + binder), reaction conditions: temperature 500°C, pressure 0.5MPa, steam / oil mass ratio 2.0:1.

[0063] Gasoline and diesel selective hydrofining unit: the catalyst uses Ni-Mo-Co / alumina (based on the catalyst, Ni content 10wt%, Mo content 5.0wt%, Co content 4.0wt%, the balance is alumina), the reaction The conditions are: temperature 150°C, pressure 4.0MPa, mass space velocity 1.5h -1 , The volume ratio of hydrogen to oil is 600:1.

[0064] Gasoline and diesel adsorption separation unit: simulated moving bed technology is adopted, the adsorbent is activated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com