Stone bathtub and preparation method thereof

A technology for bathtubs and gypsum powder, which is applied in bathtubs, showers, sanitary equipment and other directions, can solve the problems of artificial stone bathtubs that are not resistant to corrosion and aging, rapid cooling and rapid heating circulation, and cannot withstand sharp edges such as metal and other sharp objects, and achieves light weight. , low cost, variable shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

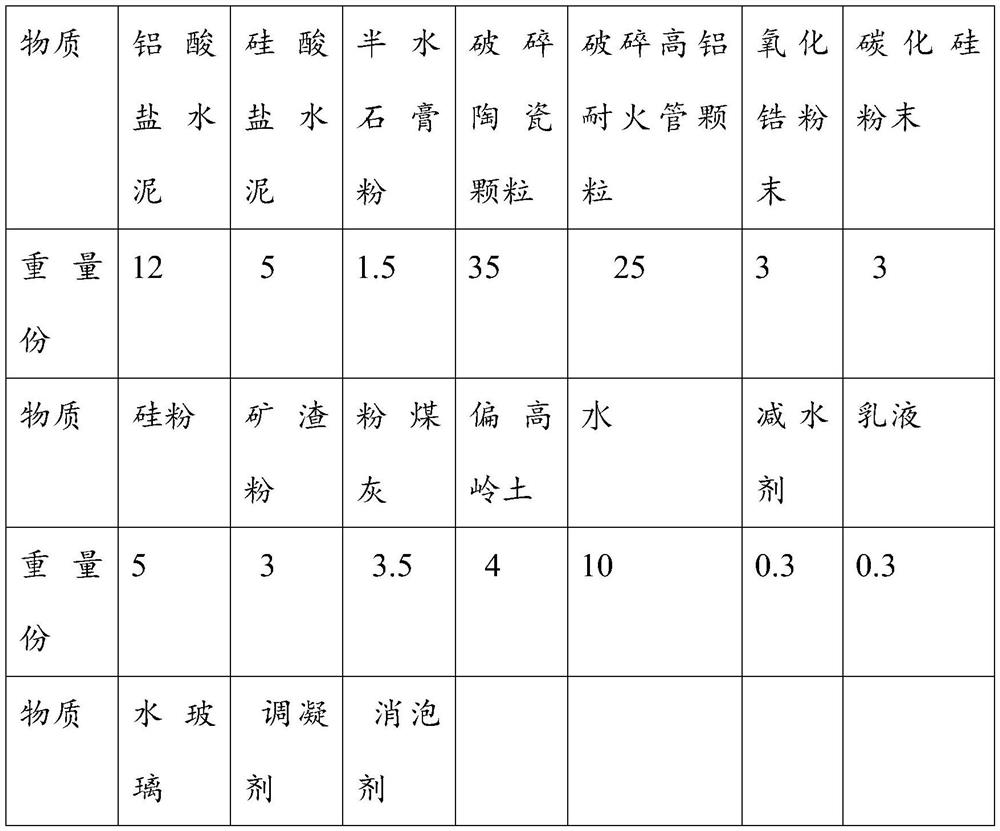

Embodiment 1

[0061] A method for preparing the above-mentioned stone bathtub, comprising the following steps:

[0062] Mix aluminate cement, Portland cement, hemihydrate gypsum powder, crushed ceramic particles, crushed high alumina refractory pipe particles, zirconia powder, silicon carbide powder, silica fume, slag powder, fly ash, metakaolin 5 Minutes, the speed is controlled at 15 rpm, then mix the water glass, water reducer, emulsion, defoamer, coagulant, water first and then add to the powder, stir for 1 minute, add fiber, stir for 2 minutes, stir Control the rotation speed at 45 rpm to obtain a mixture, control the flow expansion of the mixture to 40cm, and the viscosity to 8Pa s; pour the above mixture into the bathtub mold, demould after 1 hour, and the temperature of the bathtub after demoulding is 60°C , baked in an environment with a relative humidity of less than 30% for 1 hour to obtain the above-mentioned stone bathtub, and then spray a mixture of p-polyborazine silane and f...

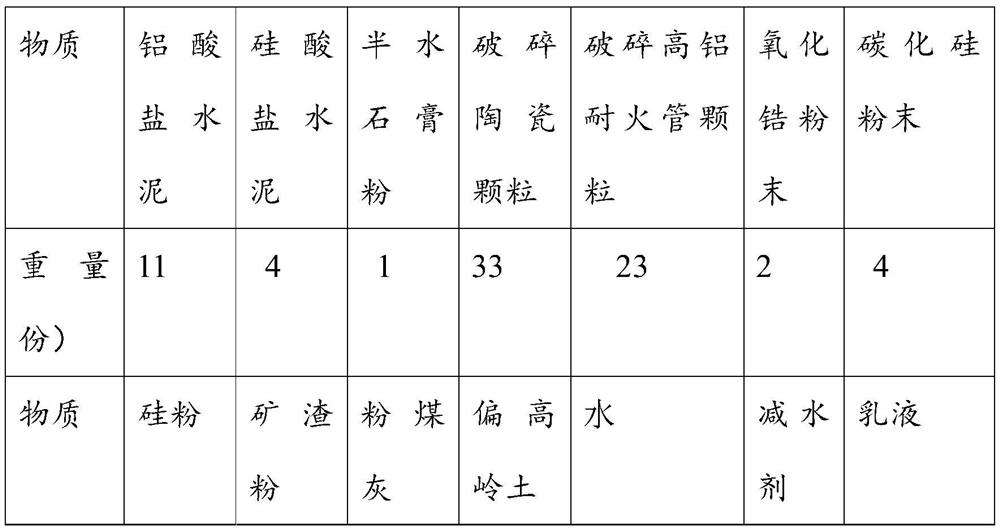

Embodiment 2

[0093] A method for preparing the above-mentioned stone bathtub, comprising the following steps:

[0094] Mix aluminate cement, Portland cement, hemihydrate gypsum powder, crushed ceramic particles, crushed high alumina refractory pipe particles, zirconia powder, silicon carbide powder, silica fume, slag powder, fly ash, metakaolin 5 Minutes, the speed is controlled at 15 rpm, then mix the water glass, water reducer, emulsion, defoamer, coagulant, water first and then add to the powder, stir for 1 minute, add fiber, stir for 2 minutes, stir Control the rotation speed at 45 rpm to obtain a mixture, control the flow expansion of the mixture to 40cm, and the viscosity to be 6Pa s; pour the above mixture into a bathtub mold, and demould after 1 hour. After demoulding, the temperature of the bathtub is 60°C , baked in an environment with a relative humidity of less than 30% for 1 hour to obtain the above-mentioned stone bathtub, and then spray a mixture of p-polyborazine silane and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com