Preparation method and application of tin selenide-selenium-doped polyacrylonitrile compound potassium ion battery negative electrode material

A polyacrylonitrile, battery negative electrode technology, applied in battery electrodes, circuits, electrical components, etc., to achieve the effect of environmental friendliness, narrow band gap, and fast kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of spinning solution: Weigh 0.7 g of anhydrous tin dichloride and 0.5 g of polyacrylonitrile and dissolve in 10 mL of N-N dimethylformamide, stir magnetically for 24 h to obtain uniform spinning solution, spare;

[0032] (2) Electrospinning: Take the uniform spinning solution prepared in the above step (1) in the syringe, set the spinning voltage to 23 kV, the plug flow rate to 0.3 mL / h, the receiving distance to 15 cm, and the temperature to 40 o C, PAN / SnCl prepared by electrospinning 2 composite fiber;

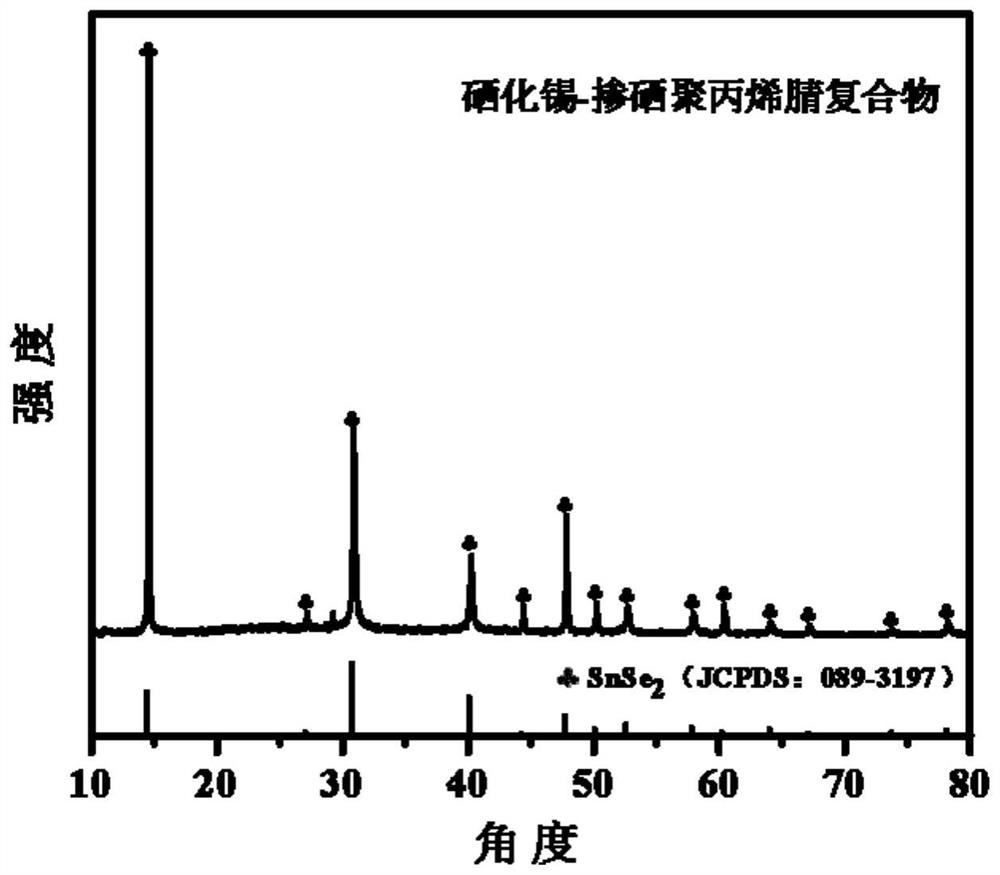

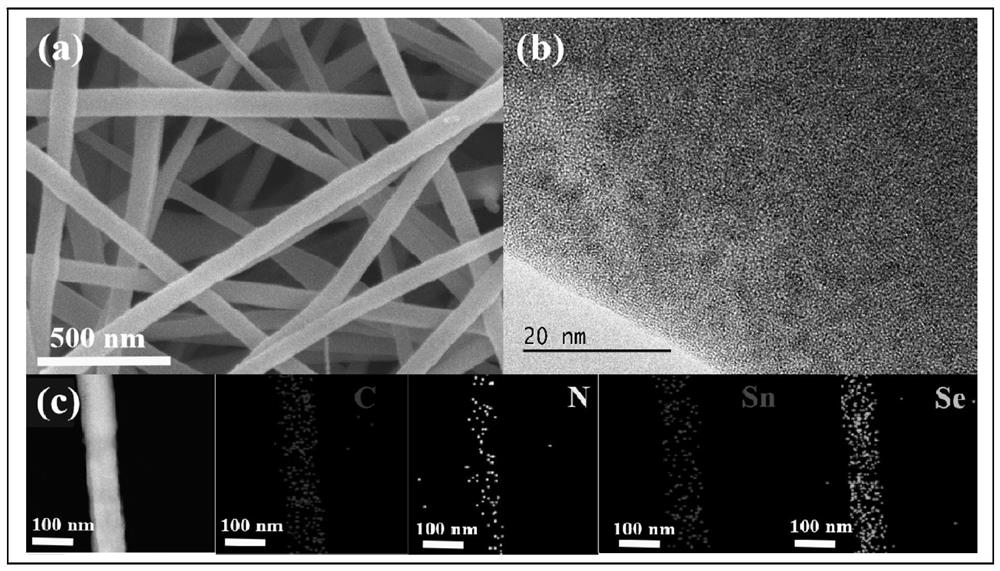

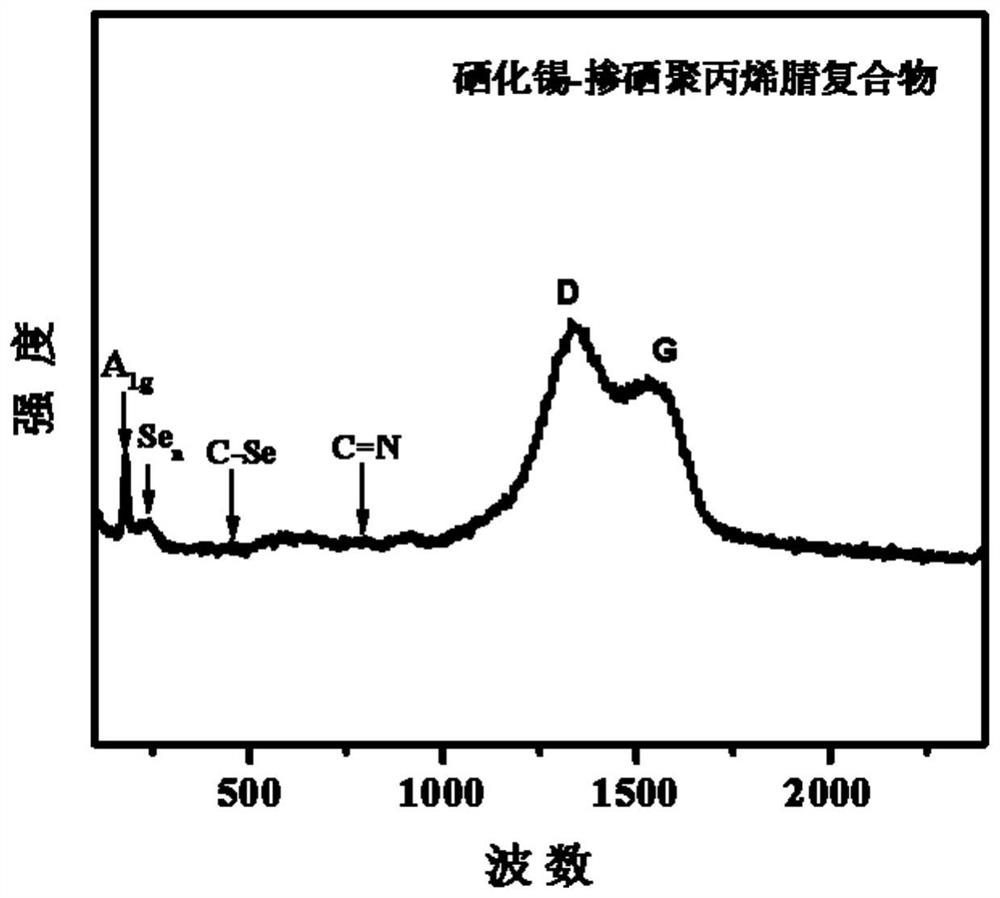

[0033] (3) Preparation of tin selenide-selenium-doped polyacrylonitrile composite material: the PAN / SnCl prepared in the above step (2) 2 The composite fiber and selenium powder were respectively placed in different corundum boats according to the mass ratio of 1:2, and were heated in an Ar atmosphere tube furnace with 5 o The heating rate of C / min is calcined at 470 °C for 1 hour, which is the tin selenide-selenium-doped polyacrylonitrile composit...

Embodiment 2

[0037] (1) Preparation of spinning solution: Weigh 0.7 g of anhydrous tin dichloride and 0.7 g of polyacrylonitrile and dissolve in 15 mL of N-N dimethylformamide, stir magnetically for 24 h to obtain uniform spinning solution, spare;

[0038] (2) Electrospinning: Take the uniform spinning solution prepared in the above step (1) in the syringe, set the spinning voltage to 23 kV, the plug flow rate to 0.6 mL / h, the receiving distance to 18 cm, and the temperature to 35 o C, PAN / SnCl prepared by electrospinning 2 composite fiber;

[0039] (3) Preparation of tin selenide-selenium-doped polyacrylonitrile composite material: the PAN / SnCl prepared in the above step (2) 2 The composite fiber and selenium powder were placed in different corundum boats according to the mass ratio of 1:2, and placed in an Ar atmosphere tube furnace for 5 o The heating rate of C / min is calcined at 500 °C for 1 hour, which is the tin selenide-selenium doped polyacrylonitrile composite material.

[004...

Embodiment 3

[0042] (1) Preparation of spinning solution: Weigh 1.4 g of stannous sulfate and 6 g of polyacrylonitrile and dissolve in 50 mL of N-N dimethylformamide, stir magnetically for 24 h to obtain a uniform spinning solution, and set aside ;

[0043] (2) Electrospinning: Take the uniform spinning solution prepared in the above step (1) in the syringe, set the spinning voltage to 25 kV, the flow rate to 0.8 mL / h, the receiving distance to 18 cm, and the temperature to 40 o C, PAN / SnCl prepared by electrospinning 2 composite fiber;

[0044] (3) Preparation of tin selenide-selenium-doped polyacrylonitrile composite material: the PAN / SnCl prepared in the above step (2) 2 The composite fiber and selenium powder were respectively placed in different corundum boats according to the mass ratio of 1:2, and placed in an Ar atmosphere tube furnace with 10 o The heating rate of C / min is calcined at 600 °C for 1 hour, which is the tin selenide-selenium-doped polyacrylonitrile composite materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com