Novel graphite phase carbon nitride polymer material, preparation method and applications thereof

A technology of graphitic carbon nitride and polymer materials, applied in nitrogen compounds, nitrogen and non-metallic compounds, chemical instruments and methods, etc. Using sunlight and other problems to achieve the effects of good crystallinity, high yield and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

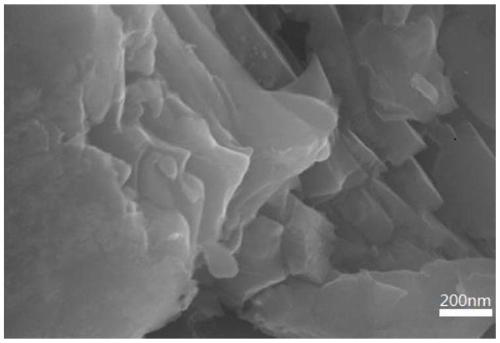

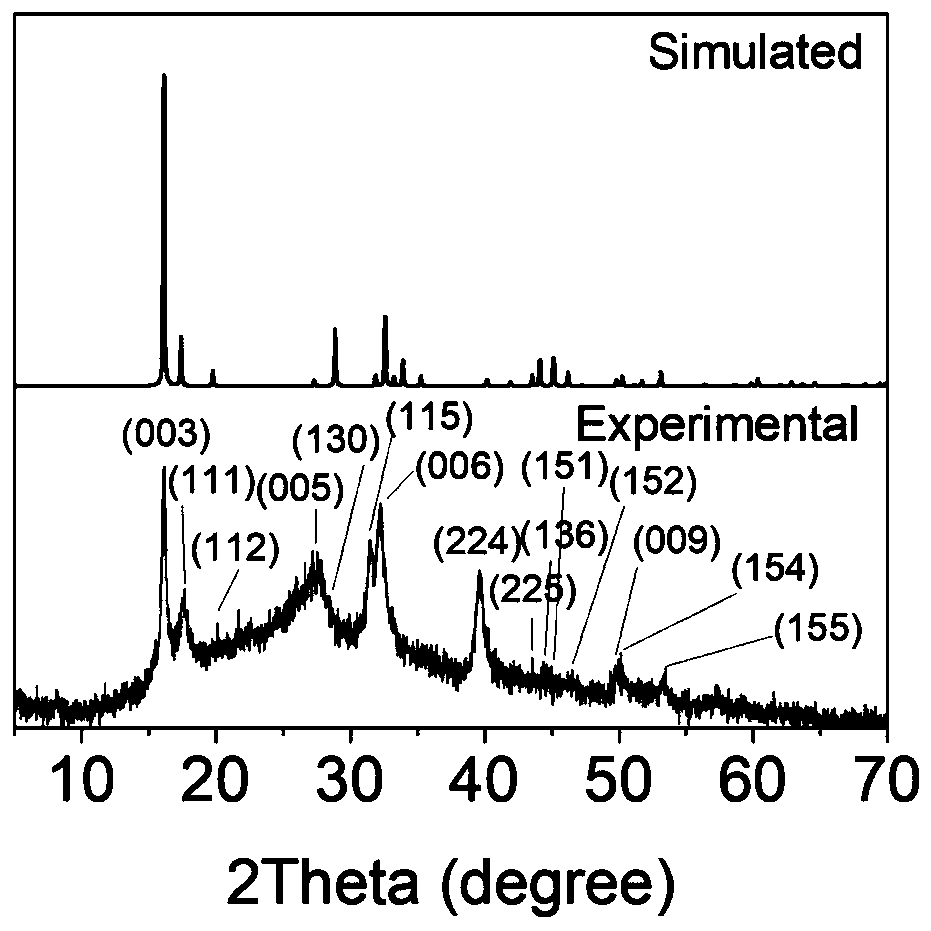

Image

Examples

Embodiment 1

[0049] The preparation method of a kind of novel graphite phase carbon nitride polymer material of the present embodiment, concrete steps are as follows:

[0050]Add 600mg of cyanuric chloride (CAS No.: 108-77-0, FW: 184.41) reaction monomer into a 50mL argon-filled PPL-lined hydrothermal synthesis reaction kettle, cut length 15cm, width 5cm, thickness of 0.05mm copper sheet, followed by ultrasonic cleaning with deionized water, absolute ethanol and acetone for 30min respectively, after drying, roll up to facilitate putting into the reactor; put the copper sheet into the appropriate position of the reactor Finally, the reaction kettle was sealed, transferred to a muffle furnace, heated to 260°C and kept for 24 hours. After the reaction was completed, it was lowered to room temperature, and the copper sheet was taken out. The sheet-shaped material loaded on the copper sheet was a new carbon nitride polymer.

[0051] Flatten the red copper sheet obtained above, tap gently with t...

Embodiment 2

[0062] The preparation method of a kind of novel graphite phase carbon nitride polymer material of the present embodiment, concrete steps are as follows:

[0063] Add 400mg of cyanuric chloride (CAS No.: 108-77-0, FW: 184.41) reaction monomer into a 50mL air-filled PPL-lined hydrothermal synthesis reaction kettle, cut length 15cm, width 5cm 1. A red copper sheet with a thickness of 0.05 mm was ultrasonically cleaned with deionized water, absolute ethanol and acetone for 30 minutes respectively, after drying, rolled up to facilitate putting into the reactor; after putting the red copper sheet into a suitable position of the reactor Seal the reaction kettle, transfer it to a muffle furnace, heat it to 280°C and keep it for 12 hours. After the reaction, cool down to room temperature, and take out the copper sheet.

[0064] The carbon nitride polymer prepared above in this example was crushed, washed with water and ethanol, and dried to obtain a new carbon nitride polymer powder. ...

Embodiment 3

[0067] The preparation method of a kind of novel graphite phase carbon nitride polymer material of the present embodiment, concrete steps are as follows:

[0068] Add 500mg of cyanuric chloride (CAS number: 108-77-0, FW: 184.41) reaction monomer into a 200mL PPL-lined hydrothermal synthesis reactor filled with nitrogen, and cut the length to 15cm and width to 5cm 1. A red copper sheet with a thickness of 0.05mm was ultrasonically cleaned with deionized water, absolute ethanol and acetone for 30 minutes respectively. After drying, it was rolled up to facilitate putting into the reaction kettle. After putting the red copper sheet into a suitable position of the reaction kettle Seal the reaction kettle, transfer it to a muffle furnace, heat it to 260°C and keep it for 18 hours. After the reaction, cool down to room temperature, and take out the copper sheet.

[0069] The carbon nitride polymer prepared above in this example was crushed, washed with water and ethanol, and dried to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com