3D chrysanthemum-like Z type Bi2S3@CoO heterojunction composite catalyst as well as preparation method and application thereof

A composite catalyst and heterojunction technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of plant damage and human health, so as to improve the absorption capacity and improve the light intensity. Response range, photocatalytic performance, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

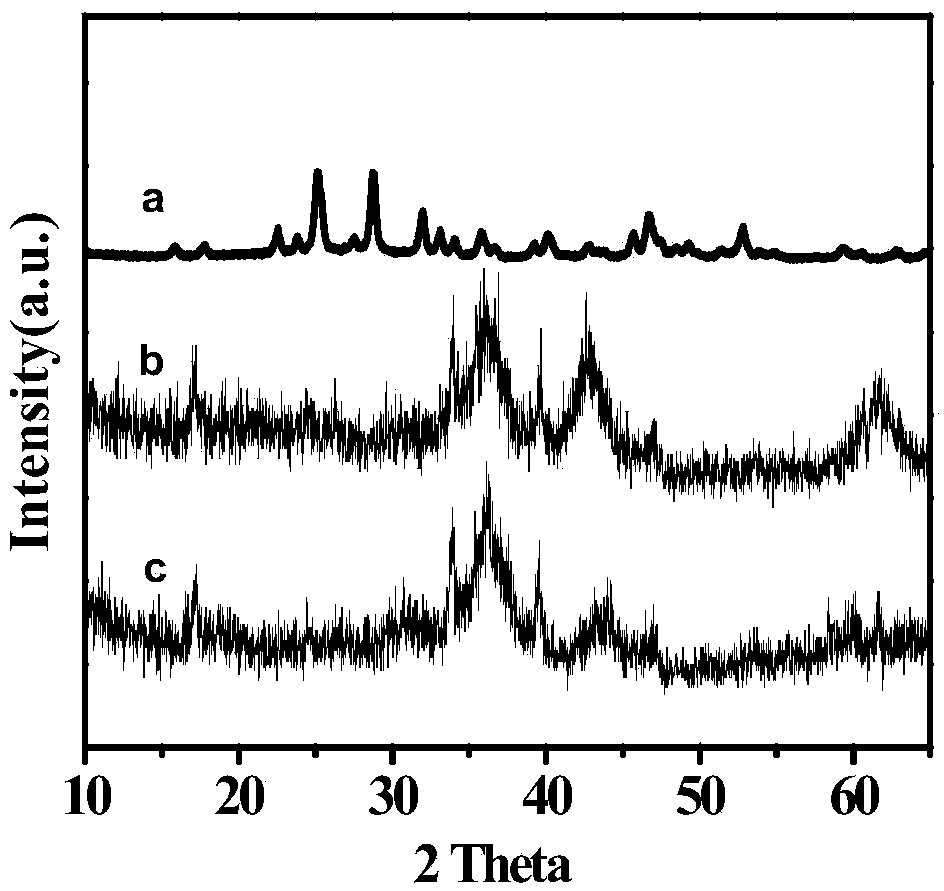

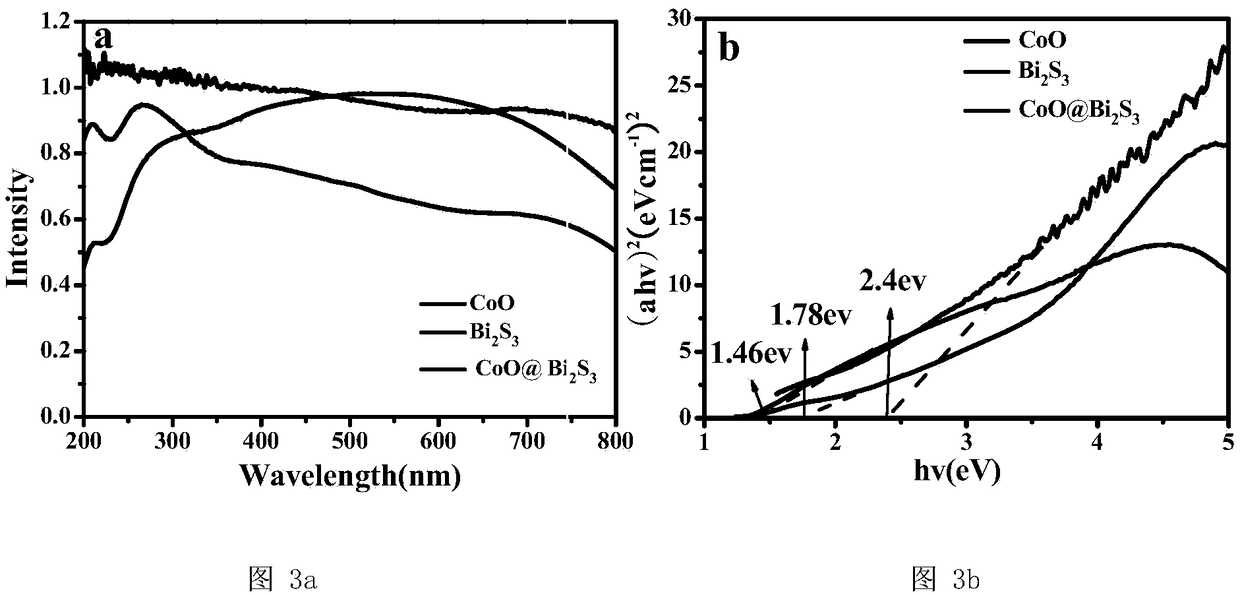

[0034] (1) Preparation of CoO

[0035] Weigh 0.582g of cobalt nitrate hexahydrate, 0.600g of urea and 0.074g of ammonium fluoride, add them into 50mL of double distilled water, keep stirring for 30min, then transfer to a 100mL hydrothermal reaction kettle, 110℃ water Thermal reaction for 6 hours. After the reaction was completed, cool to room temperature, collect the reaction product by centrifugation, and wash repeatedly with twice distilled water until the pH is neutral. Finally, it was dried in an oven at 60° C. for 12 hours. The completely dried reaction product was moved to a tube furnace, fed with nitrogen, and calcined at 300° C. for 2 h to obtain CoO.

[0036] (2) 3D chrysanthemum-shaped Z-shaped Bi 2 S 3 Preparation of @CoO Heterojunction Composite Catalysts

[0037] Weigh 600mg of CoO and 58mg of Bi(NO 3 ) 3 , was added to 30 mL of double distilled water, and stirred continuously for 20 min. Then 20mL containing 43mg Na was added dropwise 2 S aqueous solutio...

Embodiment 2

[0045] (1) 3D chrysanthemum-shaped Z-shaped Bi with different mass ratios 2 S 3 Preparation of @CoO Heterojunction Composite Catalysts

[0046] In 600mgCoO, add 23mg, 58mg, 69mg, 92mg and 115mg of Bi(NO 3 ) 3 , add 30mL of double distilled water, and continue to stir for 20min. Then add 20mL containing 17mg, 43mg, 51mg, 68mg and 85mg Na 2 The aqueous solution of S was stirred and reacted for 30 min, and the reaction product was collected by centrifugation, and washed several times with twice distilled water until the pH was neutral. Finally, it was dried in an oven at 60° C. for 12 hours. The completely dried material was moved to a tube furnace, fed with nitrogen, and calcined at 250°C for 2 hours to obtain the mass ratio Bi 2 S 3 :CoO=2:100, 5:100, 6:100, 8:100 and 10:100 3D chrysanthemum-like Z-shaped Bi 2 S 3 @CoO heterojunction composite catalyst.

[0047] (2) Degradation of organic pollutants

[0048] Method: weigh 3D chrysanthemum-shaped Z-shaped Bi 2 S 3 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com