Method and system for preparing high-whiteness and high-purity aluminum hydroxide from solid waste

An aluminum hydroxide, high-purity technology, applied in the direction of alumina/aluminum hydroxide, can solve the problems of large slag production, large sintering amount, different content, etc., and achieves short homogenization time, lower sintering temperature, and homogenization. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

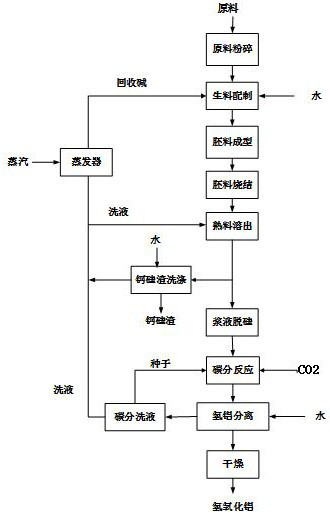

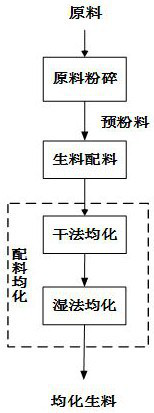

[0048] figure 1 It is a schematic diagram of the process flow for preparing high-white and high-purity aluminum hydroxide of the present invention, figure 2 It is a schematic flow chart of the raw material treatment process for preparing high-white and high-purity aluminum hydroxide of the present invention.

[0049] Such as figure 1 and figure 2 As shown, a method for preparing high-white and high-purity aluminum hydroxide includes the following steps: firstly, the raw material is pulverized to form a pre-powder, and then the pre-powder is prepared by raw material, and the blank is formed to obtain a blank, and the blank is sintered to obtain clinker , and then the clinker is dissolved to obtain a slurry, and the slurry is then subjected to slurry desiliconization, carbon reaction, hydrogen-aluminum separation and drying to prepare high-white and high-purity aluminum hydroxide; wherein,

[0050] Raw materials include aluminum-containing solid waste, calcium-containing so...

Embodiment 1

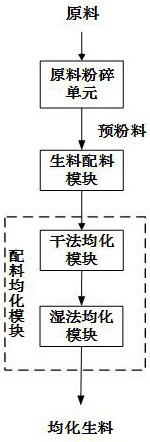

[0181] figure 1 It is a schematic diagram of the process flow for preparing high-white and high-purity aluminum hydroxide of the present invention; figure 2 It is a schematic flow chart of the raw material treatment process for preparing high-white and high-purity aluminum hydroxide of the present invention, image 3 It is a schematic structural diagram of a raw material processing system for preparing high-white and high-purity aluminum hydroxide of the present invention, Figure 6 It is a schematic structural diagram of the system for preparing high-white and high-purity aluminum hydroxide of the present invention. According to this embodiment figure 1 , 2 , 3 and 6 to prepare high-white high-purity aluminum hydroxide.

[0182] Raw material treatment of high white and high purity aluminum hydroxide

[0183] use as figure 2 and image 3 The process and flow process are used to process the raw materials for the preparation of high-white and high-purity aluminum hydrox...

Embodiment 2

[0205] Carry out batching, sintering, prepare aluminum hydroxide with reference to embodiment 1, and embodiment 1 is different:

[0206] Homogenized raw material preparation: fly ash, coal gangue, coal powder, calcium carbide slag, and soda ash are respectively fed into the pre-powder with a fineness of about 200 mesh in the Raymond mill, and the homogenization is completed according to the same formula as in Example 1. Preparation of raw materials.

[0207] Blank forming: using Figure 4 Medium G type prepares self-heating sintered embryo body, round cake shape body, diameter 10cm, thickness 3cm, cross-sectional area 200cm 2 , Use the demoulding tool to export the G-shaped blank, and finally dry the blank.

[0208] Blank material sintering: put the blank material into the roasting furnace, stack and sinter the blank material according to the height direction of the blank material to prepare clinker.

[0209] In this example, the G-type self-heating billet was sintered, put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com