Agent for realizing reduction of low-concentration cyanogen-containing coking wastewater sludge and preparation method thereof

A coking wastewater and sludge reduction technology, applied in the field of water treatment, can solve problems such as the inability to reduce chloride ions in water, substandard water quality parameters, and a large amount of sludge generated, and achieve low cost, good synergy, and environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

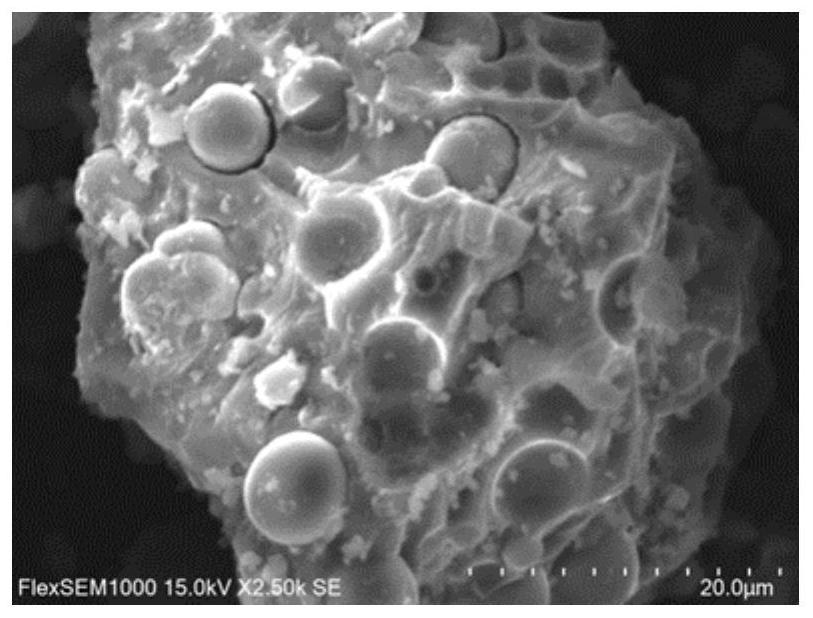

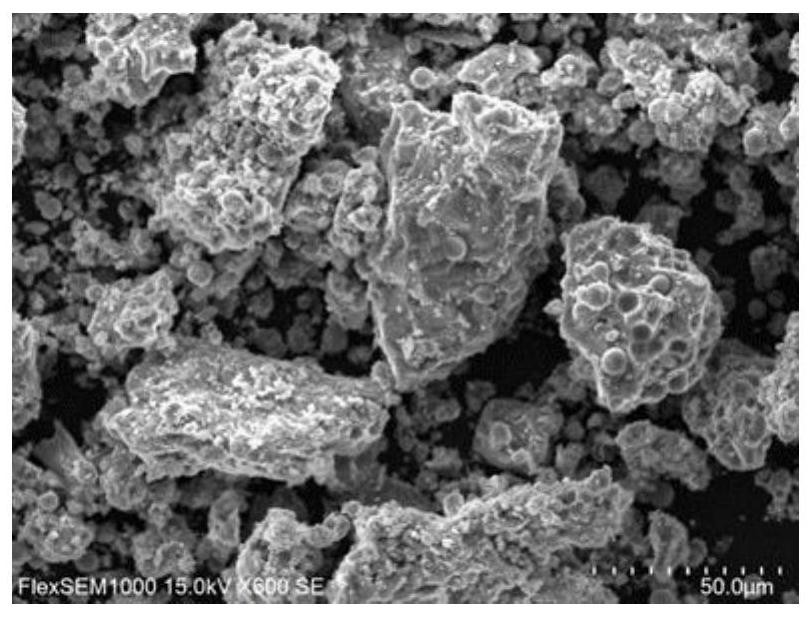

Embodiment 1

[0042] In this example, the medicament for reducing the amount of low-concentration cyanide-containing coking wastewater sludge is obtained according to the following ratio and method: add 5 g of sodium bicarbonate to 76 g of water, and after fully dissolving, use a microwave processor to dissolve 4 g of alginic acid Disperse the sodium evenly into the solution, then quickly add 9g of titanium dioxide by-products - ferrous sulfate heptahydrate, 5g of anhydrous copper sulfate, stir evenly and defoam for 45 minutes, the obtained gel state substance full of abundant voids, put it Dry in a vacuum oven at 40° C. for 60 hours, crush and pass through a 100-mesh sieve to obtain an adsorbent. After anaerobic fermentation of 10 parts of Salsify ginseng fruit and 4 parts of potassium carnate, 6 parts of quicklime were added thereto, dried and pulverized after shaking evenly, and a powder product was obtained through a 50-mesh sieve, and then mixed with 0.8 parts of alkali-hydrolyzed poly...

Embodiment 2

[0045] In this example, the medicament for realizing the reduction of low-concentration cyanide-containing coking wastewater sludge is obtained according to the following ratio and method: in 73g of water, add 7g of sodium bicarbonate, and after fully dissolving, use a microwave processor to dissolve 3.5g of seaweed Sodium bicarbonate was uniformly dispersed into the solution, and then quickly added 10g of titanium dioxide by-products-ferrous sulfate heptahydrate, 6.5g of anhydrous copper sulfate, stirred evenly and defoamed for 45 minutes, and the obtained gel-state substance filled with abundant voids, It was dried in a vacuum oven at 40° C. for 60 hours, and crushed through a 100-mesh sieve to obtain an adsorbent. After anaerobic fermentation of 8 parts of Salsify ginseng fruits and 3 parts of potassium carnate, 4 parts of quicklime were added thereto, dried and pulverized after shaking evenly, and a powder product was obtained through a 50-mesh sieve, and then mixed with 0...

Embodiment 3

[0048] The advanced treatment agent in this application is obtained according to the following ratio and method: add 8g of sodium bicarbonate to 73g of water, and after it is fully dissolved, disperse 5g of sodium alginate evenly into the solution with a microwave processor, and then add it quickly 8.5g of titanium dioxide by-products - ferrous sulfate heptahydrate, 7.5g of anhydrous copper sulfate, stirred evenly and defoamed for 45 minutes, the obtained gel substance filled with abundant voids was dried in a vacuum oven at 40°C for 60 hours , crushed through a 100-mesh sieve to obtain an adsorbent. After anaerobic fermentation of 12 parts of Salsify ginseng fruit and 4 parts of potassium carnate, 5 parts of quicklime were added thereto, dried and pulverized after shaking evenly, and the powder product was obtained through a 50-mesh sieve, and then mixed with 1.0 parts of alkali-hydrolyzed polyacrylamide powder, 48 parts of adsorbent, 11 parts of hydrated magnesium aluminum h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com